Zro2 Porous Foam Filter General information

Zro2 Porous Foam Filter is used in the production of castings from various grades of steel, cast iron, non-ferrous alloys is an effective way to ensure and improve the quality of castings.

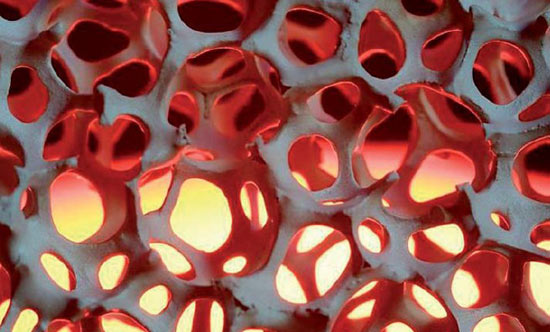

The metallurgical purity of the molten metal increases not only due to the retention of inclusions during liquid metal filtration due to the formation of a “filter cake” on the inlet side of the filter and deep filtration inside the ceramic matrix, but also due to the laminar flow in the inlet system for the metal flow.

This test suppression of turbulence leads to uniform filling of the mold, reducing erosion of the moldable mixture, and reducing the number of surface microchannels in the casting, microporosity both on the surface and inside the casting.

The decrease in the number of air inclusions in the inlet gate system due to the maintenance of the laminar flow allows reducing the contact area of the melt with the surrounding atmosphere and, therefore, prevents additional saturation of the melt with oxygen during casting.

Properly applied ceramic and foam ceramic filters do not allow the penetration of mechanical impurities, slag inclusions and films into the body of the casting.

In addition, the turbulent metal flow to the filter is converted to a laminar flow after the filter, which contributes to the quiet filling of the form and prevents the capture of gases by metal inside the form.

The main advantages when using Zro2 Porous Foam Filter

1. Reduction of marriage by impurities and inclusions.

2. Reducing the time for machining.

3. Improving the mechanical properties of cast products.

4. Increased yield.

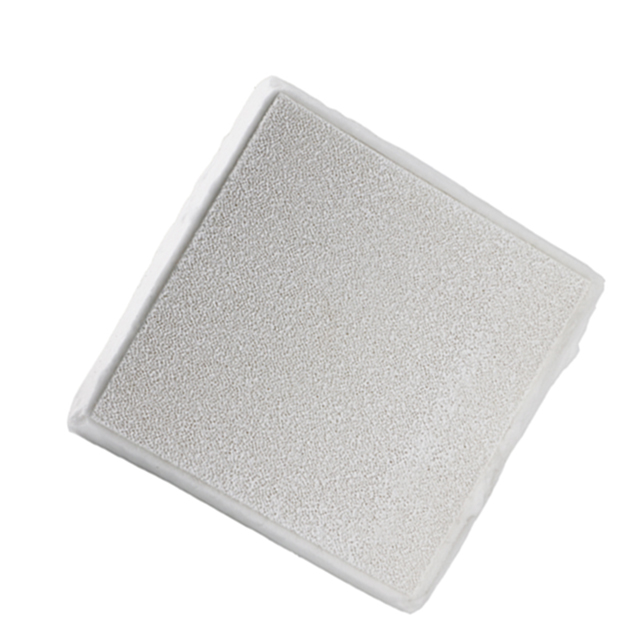

Zro2 Porous Foam Filter selection technique

1.Select the brand of ceramic foam filter in accordance with the alloy to be filtered.

Zircon filters are recommended for use only on low carbon steels, high alloy steels and special alloys where there are restrictions on the carbon content.

For carbon steel, carbon filters are best. For copper alloys, it is better to use filters made of silicon carbide.

2. Select the porosity of the filter. For experimental work, the recommended porosity is 10 PPI. The PPI value shows the number of pores per linear inch, measured by applying a ruler to the filter and counting the pores.

The larger the value, the smaller the pore size.

The need to increase the porosity is determined by the results of experimental work.

3. The choice of geometric parameters is determined based on the installation method and filter resource