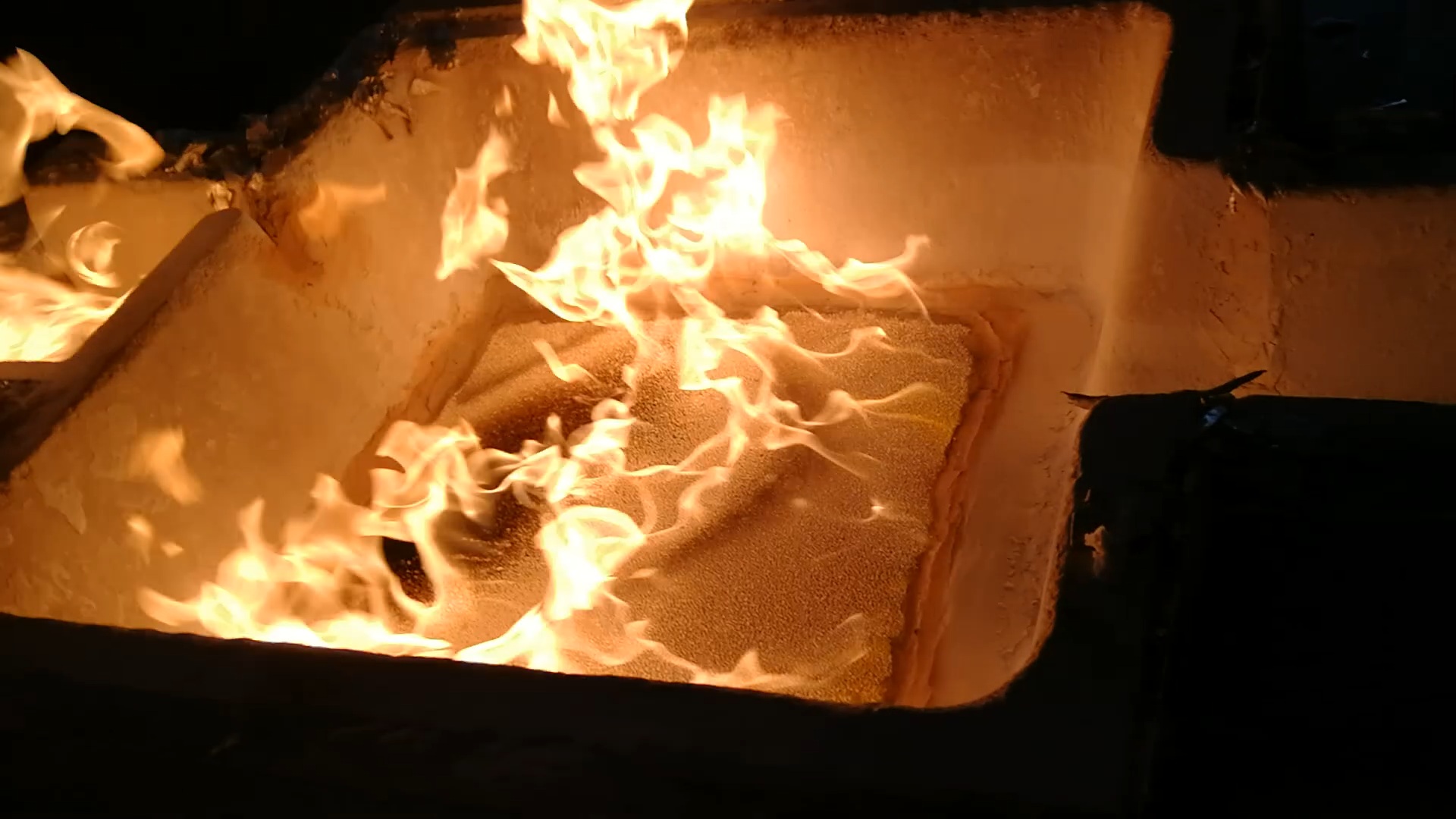

Zro2 Molten Metal Filter for filtering gray and ductile iron, as a rule, are used for installation in foundry half-molds of the bottom in specially provided for this recess. Ceramic foam effectively cleans metal melts when casting into single sand molds, metal chill molds and with continuous methods of casting non-ferrous metals (for example, filtering copper wires). Silicon carbide-based foam-ceramic filters (PCF SiC) are the universal, most common and popular filtering material in foundry.

PHYSICAL AND CHEMICAL CHARACTERISTICS

Chemical composition: SiC – min 50%, Al2O3 – max. 25%, SiO2 – max 25%;

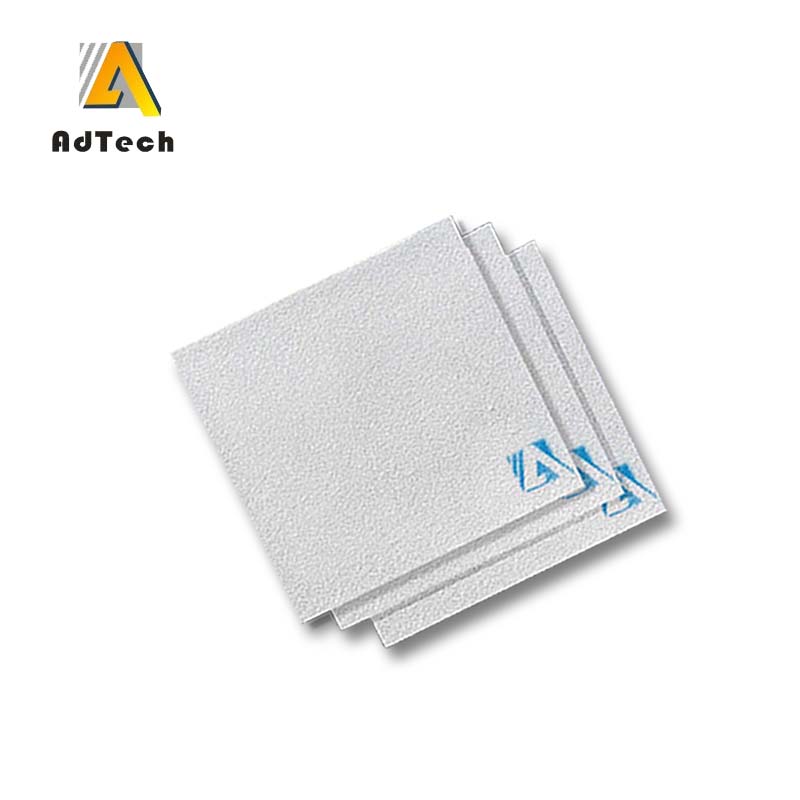

Structure: ceramic, three-dimensional developed with open pores;

Color: gray;

Porosity (pore per square inch): 10, 20 or 30 PPI;

Filtered melt temperature (cast iron, copper): max. 1480 ° C;

Basic shapes: circle, square, rectangle or other shapes on request;

Standard overall dimensions of the filter (diameter): from 30 to 150 mm;

Thickness: 10, 12, 15, 18, 20, 22, 25 or 30 mm;

Size Tolerances:

0.5 / – 1.5 mm (up to 99 mm);

0.5 / – 2.5 mm (over 100 mm);