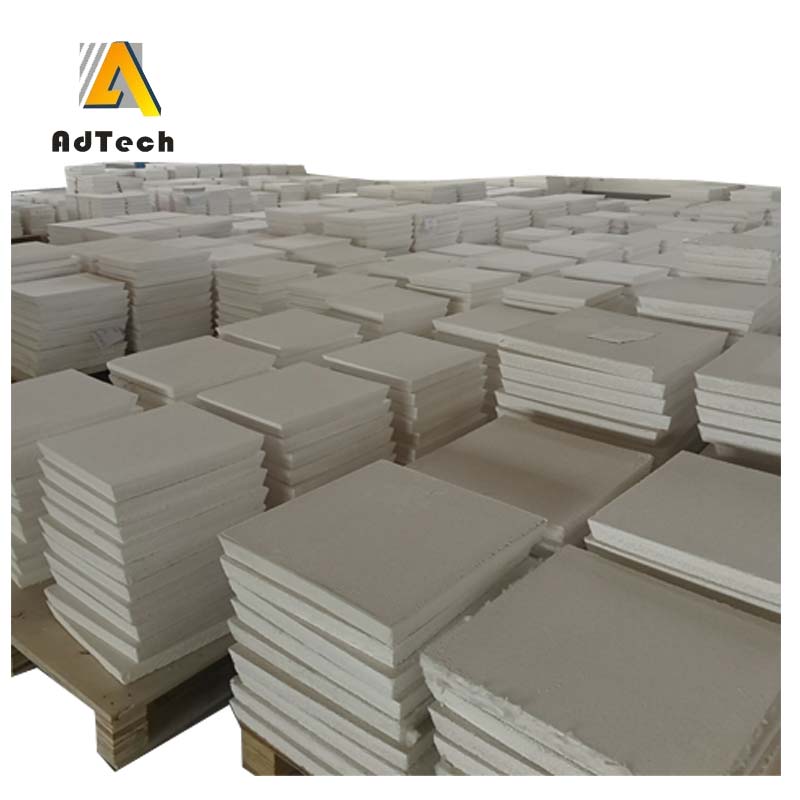

Ziroconia Filter

Ziroconia Filter has been widely used in the aluminum processing industry. There are two main modes in the application of deformed aluminum alloy melt purification technology.

In-furnace fluxing and refining, semi-continuous casting of foamed ceramic plate filtration outside the furnace, ceramic filter plate replacement is one per casting, and some aluminum processing plants add a trough-type online deaerator before filtration to improve Purification effect.

The second type is adopted on the continuous casting line, and the replacement is based on the pressure difference before and after the filter plate to determine the replacement period.

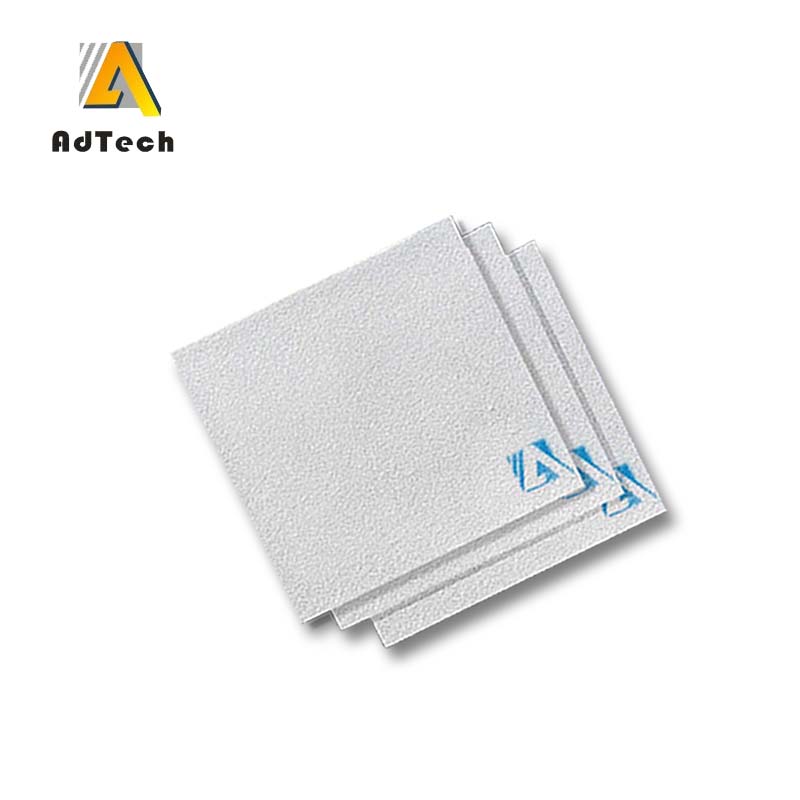

Ziroconia Filter is a type of ceramic filter plate. The zirconia-based ceramic slurry is uniformly applied to the three-dimensional network structure and the organic foam of the communicating pores as a skeleton of the carrier, and then dried and solidified and then fired at a high temperature.

Ziroconia Filter has a maximum temperature of 1760 ° C and is widely used in the filtration of various castings, high temperature master alloys and aerospace castings, magnetic materials, copper-magnesium alloy continuous casting and non-ferrous metal alloy low-pressure casting.

Ziroconia Filter Porosity

Porosity is the percentage of the total volume of the cavities in the filter plate product to the total volume of the Ceramic Filter Plate product.

Porosity determines the filtration capacity of the foam ceramic filter plate per unit volume.

The larger the porosity, the larger the filtration flow rate of the filter plate and the stronger the filtration capacity.

There are currently two main methods for determining porosity.

One is to calculate the volume of the hole in the Ziroconia Filter according to Archimedes’ law, that is, to inject water into the glass beaker with the overflow pipe until the water flows out from the overflow pipe.

The water will be tested when the water is no longer flowing out.

All the samples are gently placed in the water, then the water flows out of the overflow tube, and the volume of water in this part is measured.

The volume of the overflow water is subtracted from the physical volume of the filter plate, which is the total volume of the holes in the filter plate.

Another method is to separately determine the true density and bulk density of the sample to be tested, and then calculate the porosity of the sample according to the following formula.

These two methods have their own advantages and disadvantages.

The method of operation is simple and convenient, and the detection speed is fast, but its fatal weakness is due to the water absorption characteristics of the filter plate material itself, so that the volume of water discharged is smaller than the actual one. This causes the measured data to be too small.

Although the test process of the second method is more complicated, the influence of the water absorption of the filter plate material is excluded during the test, and the obtained data is relatively accurate.

The index of porosity is determined to be greater than 84% in this standard.

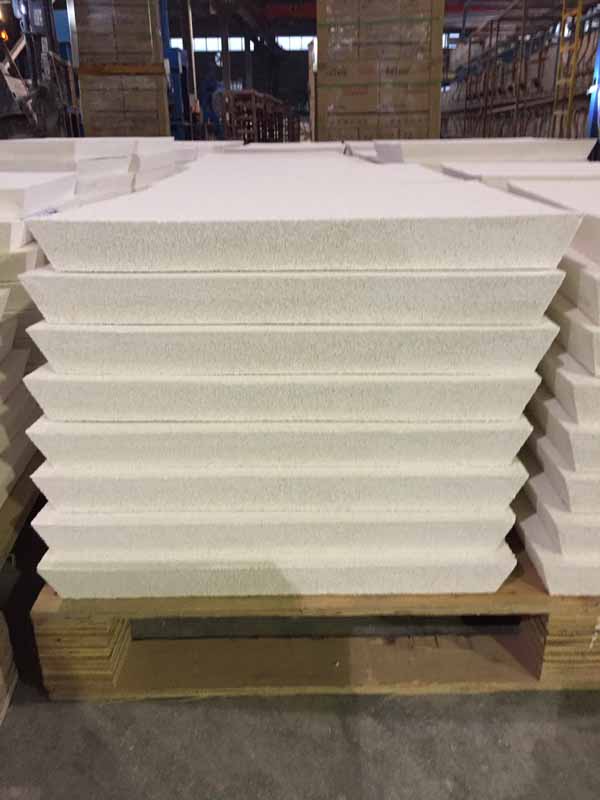

The merits of Ziroconia Filter include:

Reduce gas and inclusions that are contained in the casting, reduce the turbulence level of molten metal when filling the mold, reduce surface defects in castings, and significantly reduce the rejection rate of casting

Increase the compressive sealing of casting, increase elongation and tensile strength of casting, improved surface finish of casting, improve the mobility of molten metal, increase the filling capacity and the feeding capacity of melt.

Simplify the casting system, reduce the length of the lateral flow channel, improve casting yield.

Reduce the processing time and tool abrasion, improve surface quality of casting.

Ceramic foam possesses high mechanical strength, chemical stability, high resistance to thermal shock and liquid metal flow shock even under high temperature environment.

No slag or broken in working process, to ensure the quality and stable chemical composition of the molten metal.

Has a large and stable metal flow, even if the high content of inclusions in molten metals, ceramic foam filter will not be plugged.ery high dimensional accuracy, can be automatically placed in production line.