Ceramic Foam Filter For Liquid Aluminum must always be in the melt. After the cessation of casting, the product can be kept in a working (hot) state by placing it under a special gas or electric heater, otherwise the product is removed from the box and cannot be used further. It is economically feasible to extract (replace) the filter element after fully utilizing its filter resource. It is forbidden to clean the filter during metal casting, as this may cause damage to its surface.

Ceramic Foam Filter For Liquid Aluminum packaging and labeling

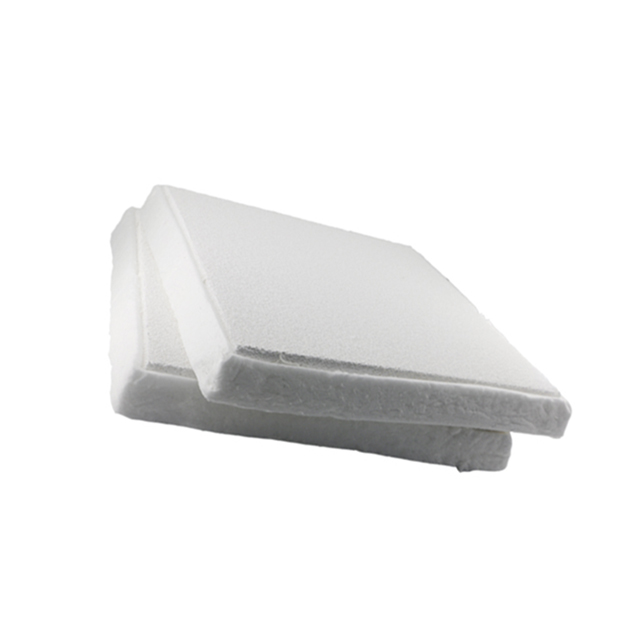

Cast filters are packaged in cardboard boxes that protect the filter from damage. Separate layers are laid with soft multilayer paper. Gaps are left between the filters to prevent mutual contact between the products in the box.

Ceramic Foam Filter For Liquid Aluminum is packed in separate cardboard boxes, which in turn are installed in the so-called “master box” and transported in an upright position.

Each box is equipped with a label containing identification data on the filters (size, type, ppi, quantity, production date, etc.) and order information (order number, customer name, etc.).

Transportation and storage

Filter cartons are mounted on pallets and transported in covered vehicles. Ceramic foam filters are stored exclusively in closed, dry storage facilities. Cardboard boxes can be stacked, but no more than seven layers. If the filters were exposed to high humidity during transportation or storage, they must be dried at 110 ° C before use until moisture is completely removed.