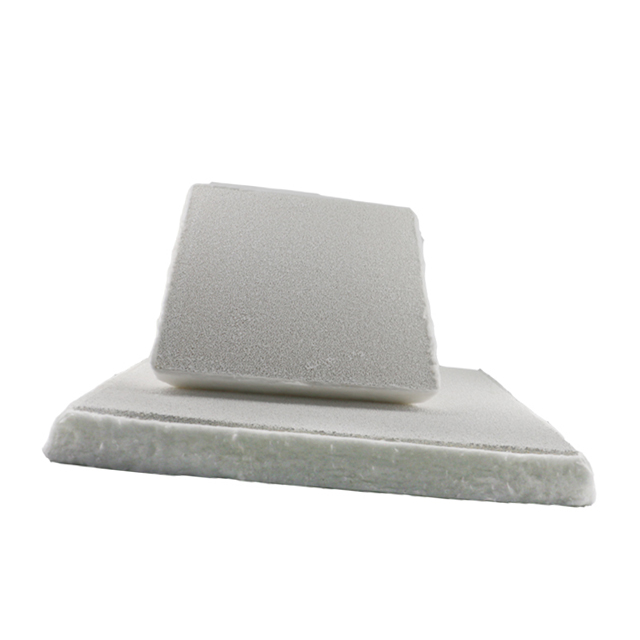

Zirconia Honeycomb Filter Closed pores and cracks on the working surfaces of the filter are not permissible. The side walls of the filter can be surface-coated with ceramics.

Handling and application

Persons working with ceramic foam filters should adapt their handling to their fragile nature. When handling filters, it is preferable to work without gloves. When removing from the boxes, the filter must be easily tapped or purged with a stream of compressed air to remove possible small ceramic particles.

When choosing the size, shape and porosity of the filters, it is necessary to comply with the applicable principles and rules that take into account the required filtering ability, casting speed and the installation location of the filter. For technical assistance, please contact the commercial and technical department of the company.

In no case do we adapt the shape or size of the filter, they must correspond to the installation location in the chamber of the gate system or in

ceramic watering can or exothermic filling. If the system does not have a collar for installing a filter, then

Zirconia Honeycomb Filter can be made with a slope for its landing, which will facilitate its exit to the surface after casting.

technical parameters of application

The values in the table are based on measurements made so far and knowledge accumulated so far. They can vary depending on the specific conditions in the foundries (temperature and level of metal contamination, the installation location of the filter in the gate system, etc.).

Filter packaging and labeling

Zirconia Honeycomb Filter is packaged in cardboard boxes that protect the filter from damage. Separate layers are laid with soft multilayer paper. Clearances are left between the filters to prevent mutual contact of the filters in the box.

Each box is equipped with a self-adhesive label containing identification data on the filters (size, type, ppi, quantity, production date, etc.) and order information (order number, customer name, etc.).

Transportation and storage

Cardboard boxes and containers with ceramic foam filters are transported in covered vehicles. Ceramic foam filters are stored exclusively in closed, dry storage facilities. Stacking cardboard boxes is allowed in max. seven layers one above the other. If the filters were subject to high humidity during transportation and storage, they will have to be dried at 110 ° C before use until all moisture is removed.