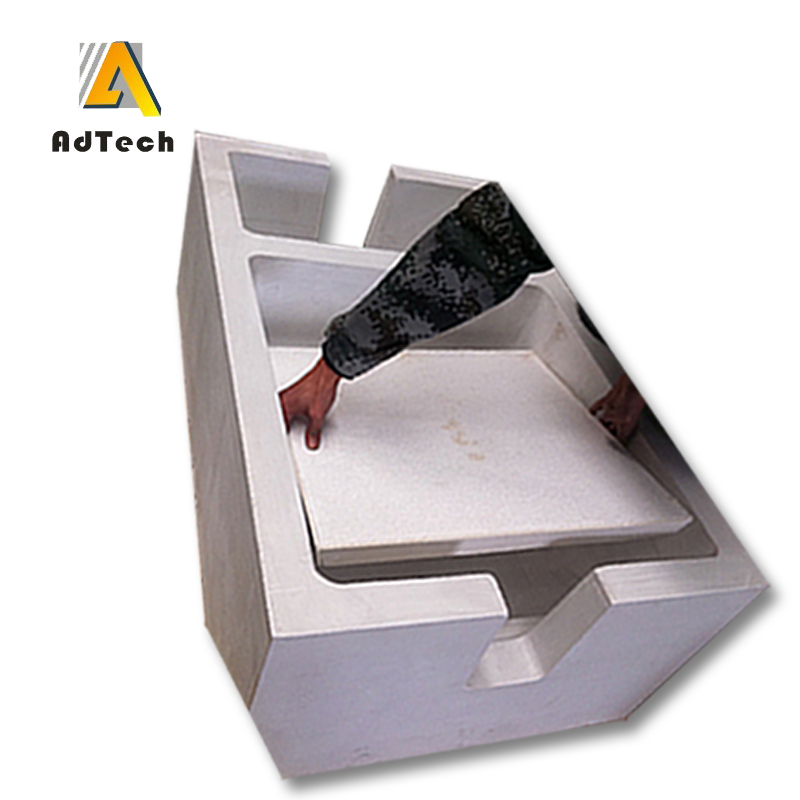

Zirconia Foam Ceramic Filter For Aluminium Foundry

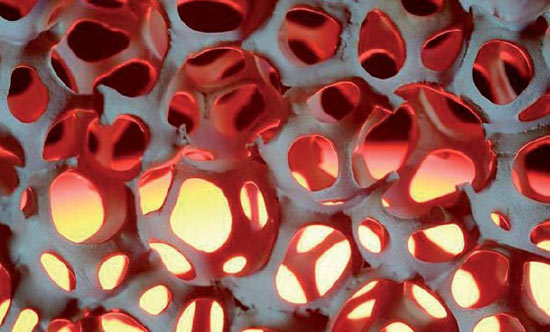

The effect of CeO2 on the properties of alumina-based foam ceramic filters was investigated using an organic foam impregnation process.

The microstructure of the sample was investigated by scanning electron microscopy (SEM) by measuring the normal temperature compressive strength, thermal shock stability, permeability and other properties of the sample.

The effects of different contents of CeO2 on the properties of alumina-based ceramic foam filters were investigated in detail.

The use of CeO2 as an additive promotes the formation of a liquid phase, lowers the firing temperature of the alumina-based foamed ceramic, and improves the microstructure and properties of the ceramic body.

The thermal shock resistance and compressive strength are optimal when the CeO2 content is 3%.