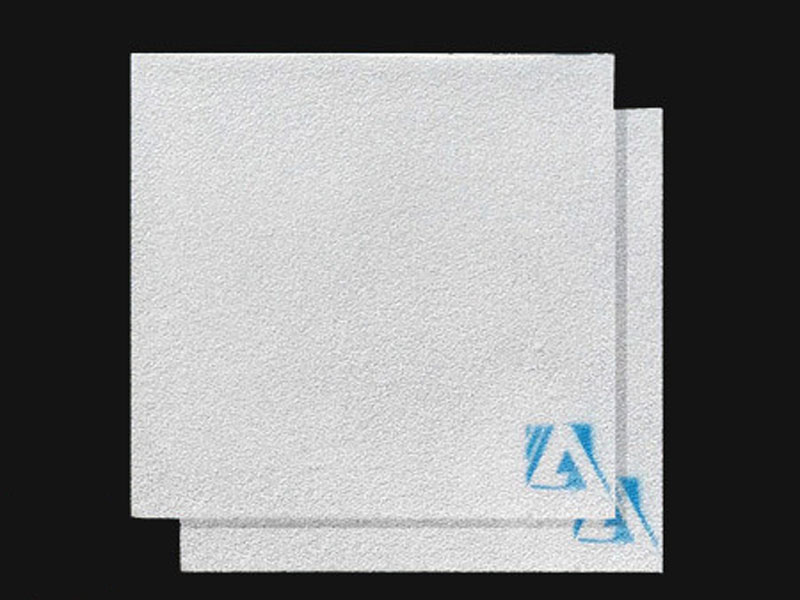

Features of Zirconia “ceramic foam filter“.

1. The zirconia porous ceramic filter uses a three-dimensional network structure and an organic foam body connected to pores as a carrier;

2. The zirconia ceramic foam filter invades the special ZrO2 molten material with thixotropy;

3. The zirconia ceramic foam plate adopts the automatic extrusion process of square correction center distance so that the slurry is evenly coated on the foam body skeleton of the carrier;

4. The zirconia porous ceramic filter is dried, solidified, and fired at high temperature, and has expanded cotton sealing edges.

With the economic recovery and development of developing countries such as South America and Southeast Asia, the demand for aluminum and aluminum alloy products is increasing, and the quality requirements for the aluminum alloy are also increasing, which stimulates the development of zirconia foam ceramics. filter consumption.

In order to meet the needs of the market, Adtech Metallurgical Materials Co., Ltd. introduced the latest international technology, developed a high-performance zirconia porous ceramic filter, and obtained relevant national patents.

Ceramic foam filter