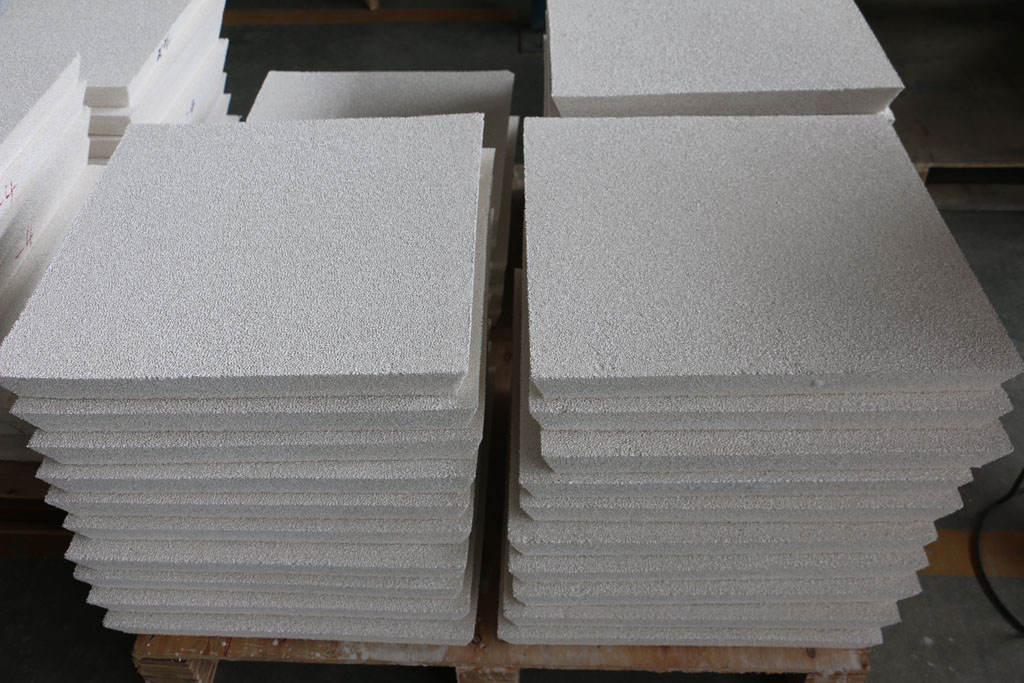

Why does White Ceramic Foam Filter turn black when baked?

To deal with the fumes generated by the firing of foam ceramics, it is first necessary to understand the composition of the polyurethane sponge used in the foam ceramics, and then analyze the smoke components and the amount of smoke generated during the combustion process.

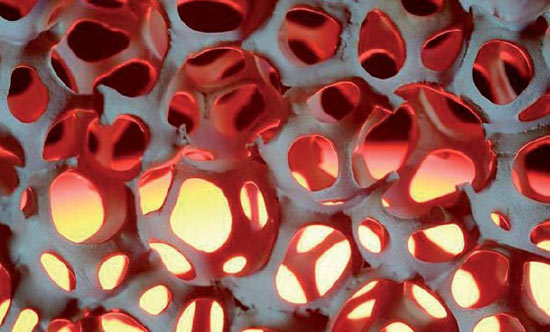

The flexible polyurethane porous mesh sponge used for foam ceramics is a closed-cell sponge foam which is foamed from chemical raw materials such as toluene diisocyanate, polyether polyol, amine catalyst, dichloromethane, silicone oil, etc., and then uses acetylene or hydrogen. It is opened into a three-dimensional through-mesh structure.

The open-cell polyurethane sponge has a density of only 0.03 to 0.05 g/cm3.

Sponges are made from a variety of chemical raw materials, their chemical composition is complex, and there are very few reports on their chemical composition.

It is reported that the chemical composition of the sponge is roughly polyurethane, polypropylene glycol, diphenylmethane diisocyanate, toluene diisocyanate, etc., and has the characteristics of molecular chain length and large molecular weight.

The foaming of the White Ceramic Foam Filter during the firing process is harmful to the environment. Therefore, with the increasingly strict national environmental protection requirements, environmental protection in the production process has become a top priority for manufacturers.