What Is Ceramic Foam Filter

The group of inventions relates to ceramic filters suitable for filtering molten metal.

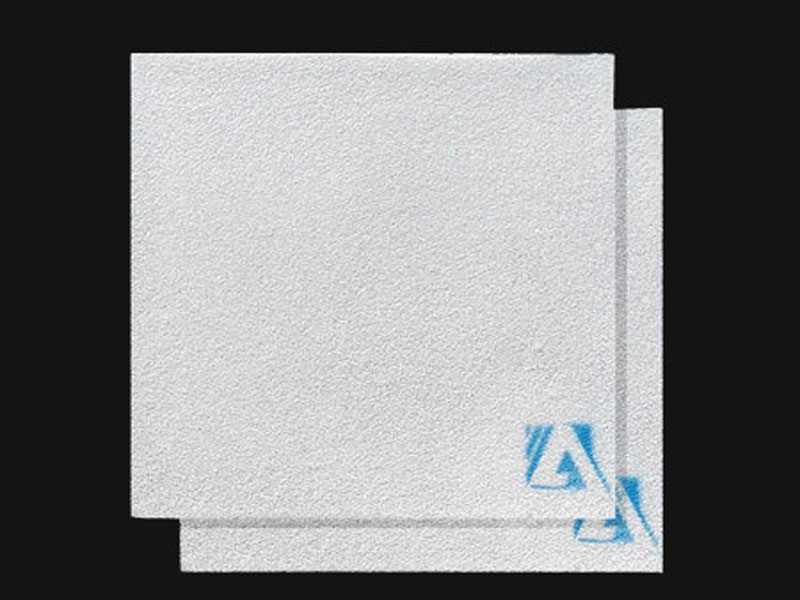

The ceramic filter contains a carbon coating deposited on refractory materials bonded with ceramic binders.

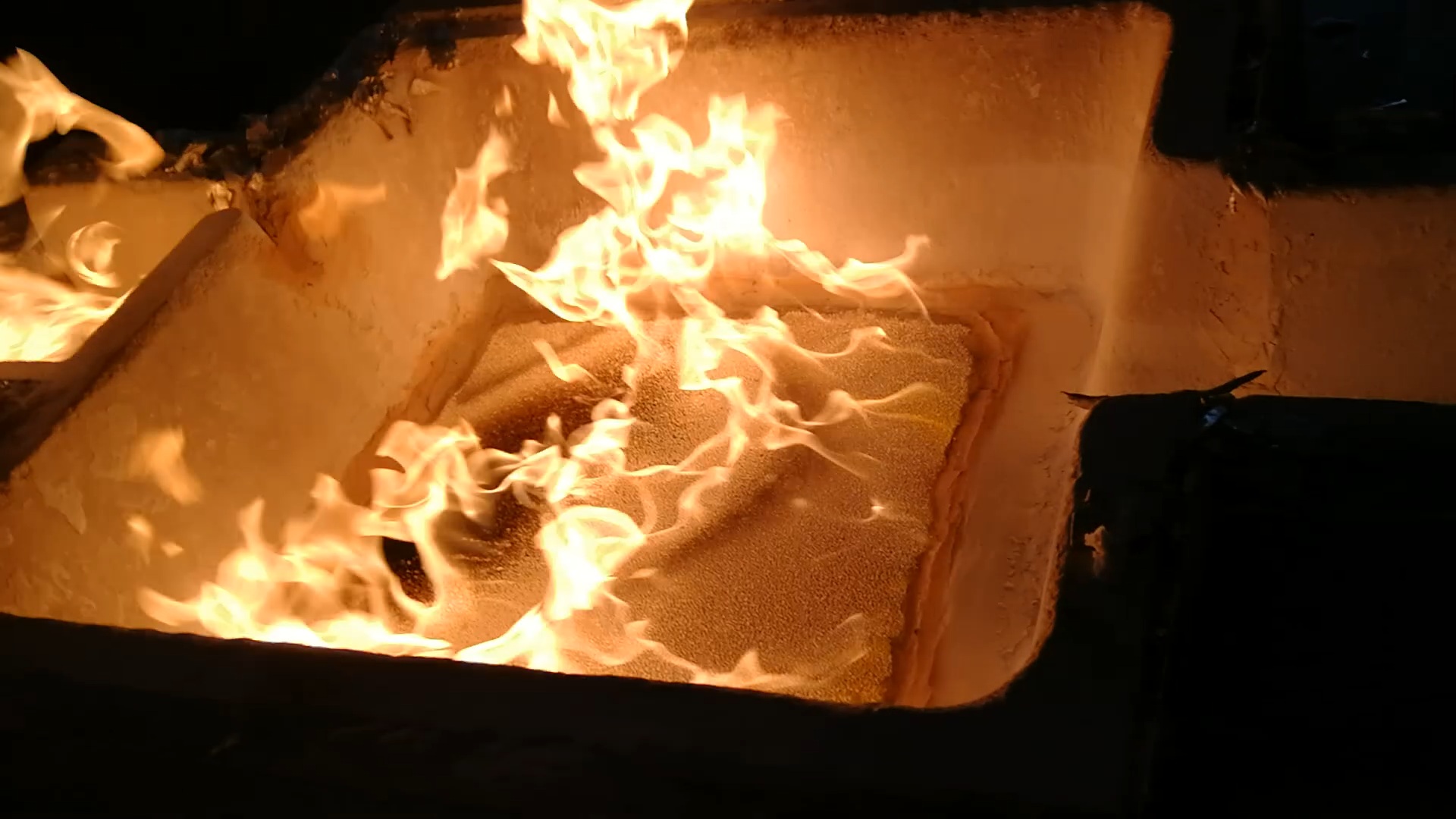

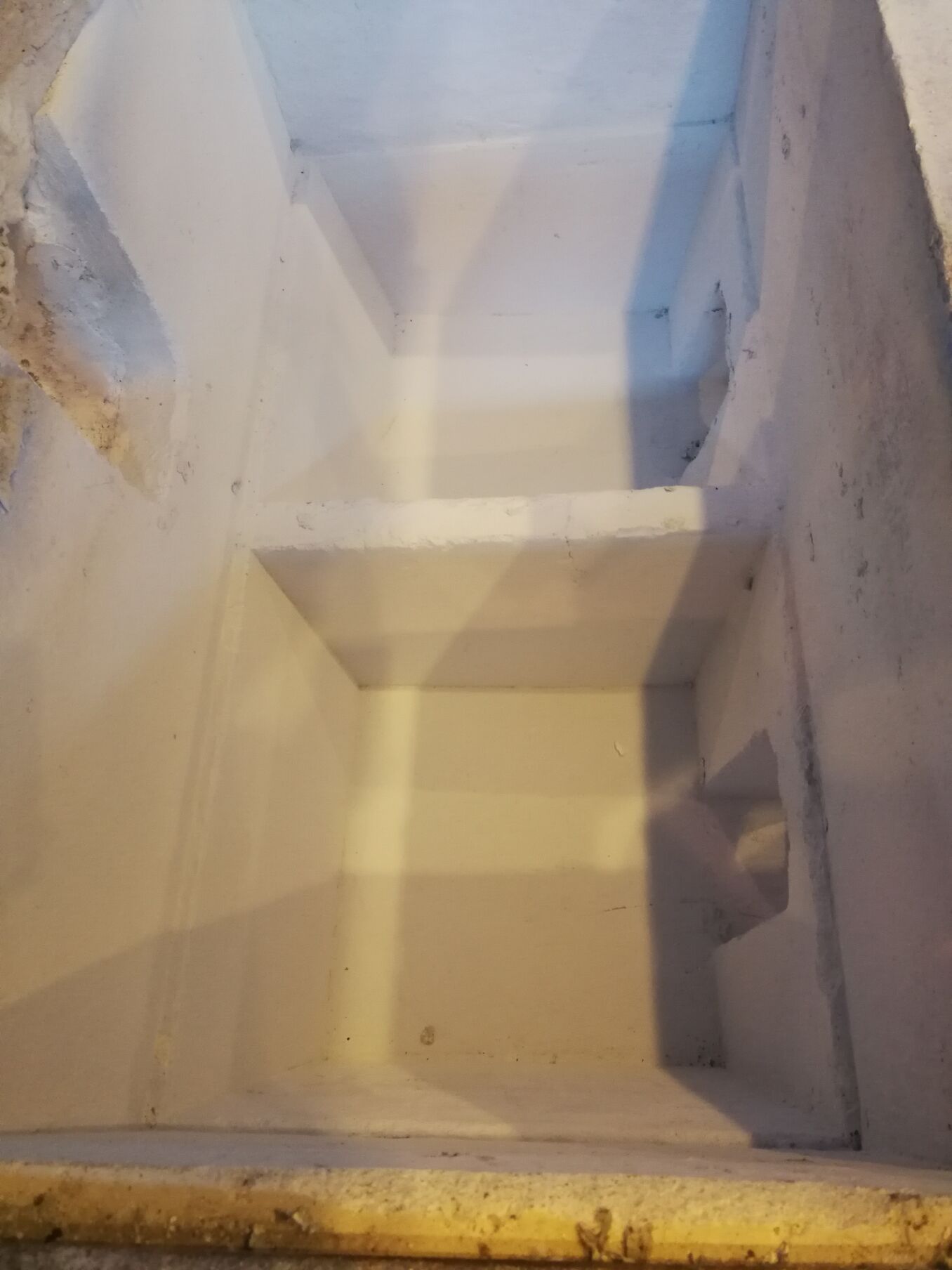

A suspension is prepared containing refractory materials, a ceramic binder, and a liquid carrier. The suspension is coated on a porous foam obtained from thermoplastic materials.

Coated foam is dried. Carbon coating is applied and the product obtained is dried.

The present invention relates to a filter suitable for filtering molten metal, in particular to a ceramic filter containing a carbon coating.

The present invention also relates to a method for manufacturing said filter.

In the manufacture of castings, the proportion of defective castings associated with casting defects, such as non-metallic acquired impurities, usually accounts for 50% -60% of the total waste. Acquired impurities not only worsen the strongly mechanical properties of the casting, but also have a harmful effect on its working properties and appearance.

Refining a casting molten alloy to reduce or eliminate various non-metallic acquired impurities is definitely a very important technical tool for producing high quality castings.

The task of cleaning a liquid alloy for casting can be effectively achieved through the use of filtering techniques.

The filtering technique has been used in the foundry industry for about several decades.

Initially, only simple filters, such as a thin wire mesh, a porous steel plate and a porous ceramic insert, were inserted into the casting system to filter out a large block of acquired impurities.

Although a porous sintered ceramic filter, first developed in the USA in the early 1970s, solved the problems of particles passing easily through it and inconvenient use, its porosity was low, usually less than 50%, and the rate of flow of liquid metal was low , as well as in a pressed ceramic cassette filter, developed for the first time in the USA in the early 1980s.

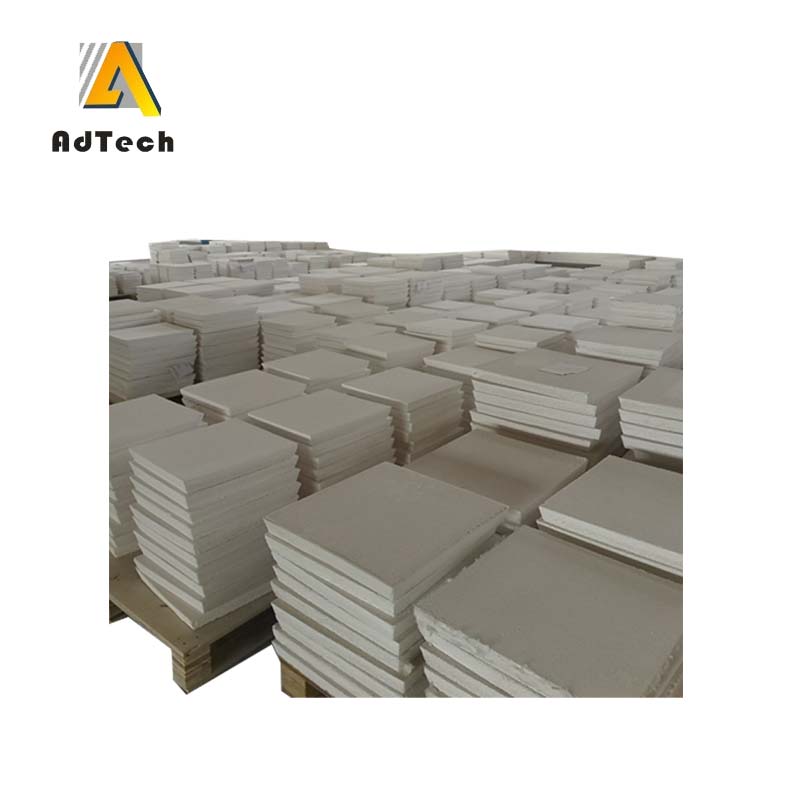

What Is Ceramic Foam Filter? The foamed ceramic filtration technique has evolved rapidly since the filter for aluminum foamed ceramic alloy was successfully developed for the first time in 1978.

What Is Ceramic Foam Filter? Ceramic Foam Filter on the market mainly include an alumina filter for filtering aluminum metal, a silicon carbide filter for filtering cast iron, and a zirconia filter for filtering molten steel.

Among them, an alumina filter and a silicon carbide filter cannot be used to filter molten steel, due to the insufficiently high temperature resistance and thermal shock resistance characteristics. A zirconia filter for filtering molten steel has a high manufacturing cost.

The filter described in the literature contains carbon based material that has higher refractory properties.

A refractory material containing carbon-based material can withstand temperatures greater than that of molten metal and prevent metal leakage; for this reason, such a material has high strength and a better characteristic of thermal shock resistance at high temperature.

Where the specified filter contains a monolithic substrate formed of a refractory material such as aluminum oxide, mullite, powdered zirconium, zirconia, spinel, cordierite, lithium, aluminosilicate, titanate, feldspar, quartz, colloidal silicon oxide, silicon carbide, kaolin, titanate aluminum, silicates, aluminates and their mixture.

Carbon-based coatings are applied to the surface of the screen or used as a termite.

The specified carbon coating is not affected by the sintering process.

The specified coating is obtained from powdered graphite, and the termite material can be mixed with it.