Uzbekistan China Foundry Filter uses aluminum filtration, which is suitable for long-term high temperature loads. Ceramic foam filter has excellent thermal shock resistance and corrosion resistance.

Clean molten metal can produce higher quality castings, less scrap and fewer inclusion defects, all of which help increase profits.

Ceramic foam filter for casting is installed in the CFF filter box. After the molten aluminum is degassed, the CFF filter system works.

The filter box has good heat preservation performance.

The CFF filter box and pouring trough are as close as possible to the switchboard.

The reason is that the flow distance of the filtered aluminum liquid can be shortened, and the re-oxidation of oxides can be reduced or avoided.

The molten aluminum flows out from the furnace mouth through the filter box, and then flows through the tank to the washing tank.

The selection of Uzbekistan China Foundry Filter for foundry must be based on the flow of molten aluminum.

Secondly, consider the cleanliness of the melt, the maximum inclusion content and the total output of the melt.

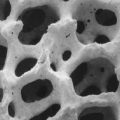

The filtering effect of the molten metal filter is mainly ensured by its size and porosity.

The greater the porosity of the filter plate, the worse the slag removal effect. For aluminum castings with higher requirements, foam ceramic filters for casting with smaller porosity should be used.

In order to reduce the influence of gas and non-metallic inclusions, people have put forward strict requirements on the raw materials and smelting process of alloy preparation on the one hand.

On the other hand, they are committed to the research and application of advanced new technologies for melt purification.

Since 2012, AdTech has been committed to the research of on-line degassing devices and filtering devices for melt purification technology.

At present, AdTech molten aluminum purification equipment has been widely used in aluminum foundries. Ceramic foam filter (CFF) filtration technology is the most economical filtration method.

Molten aluminum filters are usually used in standard sizes (inches) with a porosity of 10 to 60 PPI (pores per linear inch).

The size of the ceramic foam filter depends on its porosity, which is selected according to the filtering capacity, pouring time and the layout of the CFF filter box.

The choice of the porosity of the molten aluminum filter element depends on the specific alloy, the temperature of the casting, the degree of contamination of the metal, and the required output quality.