Use Foundry Filters during the smelting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, which is prone to oxidation, easily reacts with water vapor to absorb hydrogen, and easily forms various forms of non-metallic slag (and coarse intermetallic particles, etc.). Wait.

On the other hand, part of the waste material in the composition charge carries some non-aluminum impurities during the circulation.

Since the waste comes from the process waste and waste of the various processes of the factory and the waste outside the factory, the route is different, the composition is complex, and the quality is also poor.

Use Foundry Filters for these impurities which tend to cause bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, thereby further affecting the processing properties, mechanical properties, corrosion resistance and appearance quality of the product.

Foundry Filters significantly improves the quality of castings and facilitates cutting, reducing tool wear and reducing manufacturing costs.

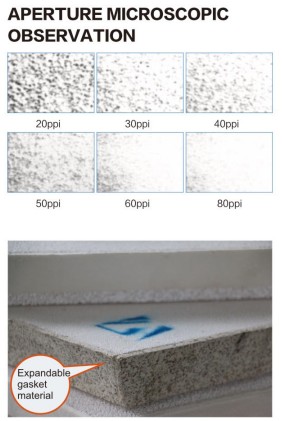

Foundry Filters has excellent thermal shock resistance, strength and high porosity and specific surface area. It can filter and adsorb as little inclusions as possible in the molten metal.

With its unique rectification effect, smooth and rapid laminar flow is prevented, and bubbles are prevented from entering, which is suitable for different refractoriness and casting speed requirements in the foundry industry.