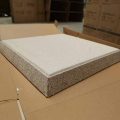

Use Foundry Ceramic Filters which adopts a three-dimensional network structure and an organic bubble communicating with pores as a carrier, infiltrates the thixotropic alumina slurry.

Use Foundry Ceramic Filters uses a four-center correction center distance automatic extrusion process.

he slurry was evenly applied to the carrier’s foam body skeleton, and baked and cured at a high temperature of 1180°C.

Use Foundry Ceramic Filters installed in the filter box for aluminum alloy liquid impurities filter, aluminum water foam ceramic filter to meet the production of high value-added, high-tech performance aviation, transportation and other aluminum alloy precision casting. Such as: computer hard drives, printing PS base, can making materials, jet turbine engine fan blades and other products.

Foundry Ceramic Filters Advantages:

1. Using the principle of adsorption, it can effectively remove large inclusions in the aluminum liquid and effectively adsorb fine inclusions of small size;

2. Do not drop slag, effectively reduce the pollution of aluminum liquid;

3. Good thermal shock resistance and improved resistance to molten metal corrosion;

4. Automated assembly line production, three calibration procedures, accurate dimensions, and more in line with the filter box;

5. Improve surface quality, improve product performance, and improve microstructure.

Foundry Ceramic Filters Product Uses:

AdTech’s aluminum water Foundry Ceramic Filters uses a three-dimensional mesh structure and an organic foam body that communicates with air holes as a carrier, infiltrating it into a thixotropic aluminum oxide slurry, and using a square-corrected center distance automatic extrusion The process is such that the slurry is evenly deposited on the foam body skeleton of the carrier, and baked and cured at a high temperature of 1180°C. Installed in the filter box for aluminum alloy liquid impurity filtration, to meet the production of high value-added, high-tech performance aviation, transportation and other aluminum alloy precision casting. Such as: computer hard drives, printing PS base, can making materials, jet turbine engine fan blades and other products.