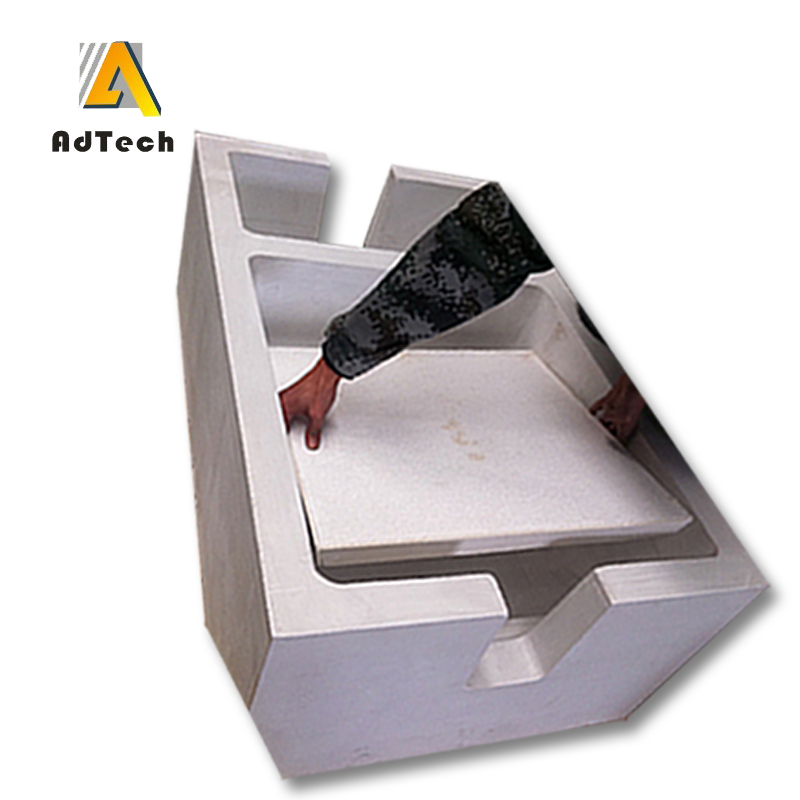

Use Foam Furnace Filter to clean the slags in the molten aluminium, which is made by Adtech China the manufacture. pls contact sales@adtechamm.com

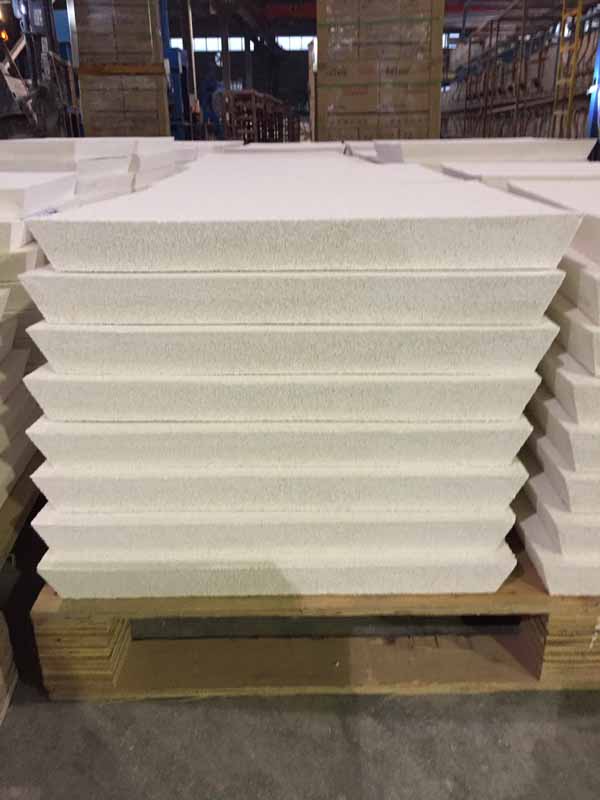

Porosity is the percentage of the total volume of the cavities in the filter foam plate to the total volume of the filter plate product.

The porosity determines the filtration capacity of the foam ceramic filter plate per unit volume.

The larger the porosity, the larger the filtration flow rate of the filter plate and the stronger the filtration capacity, and vice versa.

Foam Ceramic Filter Folding Compressive Strength

In the process of transportation and use of the filter plate, ceramic filter plate must withstand the impact of a certain pressure from the outside, so the index of compressive strength is also introduced in the standard as one of the basis for measuring the quality of the filter plate.

The higher the compressive strength, the more durable the product, the better the quality, and vice versa.

If you want to use Foam Furnace Filter, pls contact sales@adtechamm.com

Ceramic foam Filter folding thermal shock resistance

Thermal shock resistance refers to the resistance of foam ceramic filter plates to damage caused by rapid temperature changes. In the use of foam ceramic filter plates.

Filtration should begin before the filter plate is gradually preheated to the temperature of the filtered aluminum melt.

This requires the filter plate to have a certain thermal shock resistance. The better the thermal shock resistance, the more durable the filter plate and the better the quality.