When Use Filter Foundry for Aluminium Casting Factory, in general, need to pay attention to the following aspects.

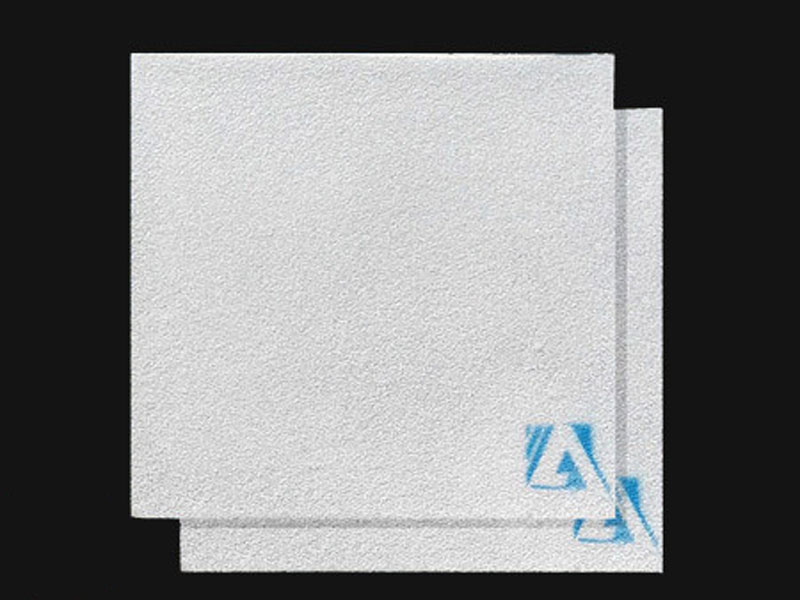

Correct selection of filter plates

The size of the filter plate and the number of holes must be selected in consideration of the flow rate range of the specific casting type, the maximum liquid level of the metal during filtration, the total filtration amount, and the cleanliness of the original aluminum liquid.

The pre-melt filtration treatment can not be ignored

Such as the normal slag and clearing the furnace of the aluminum melting furnace and the holding furnace.

The refining in the furnace. In particular, an in-line degassing unit is still necessary because it not only reduces the hydrogen content of the melt, but also removes some of the non-metallic inclusions.

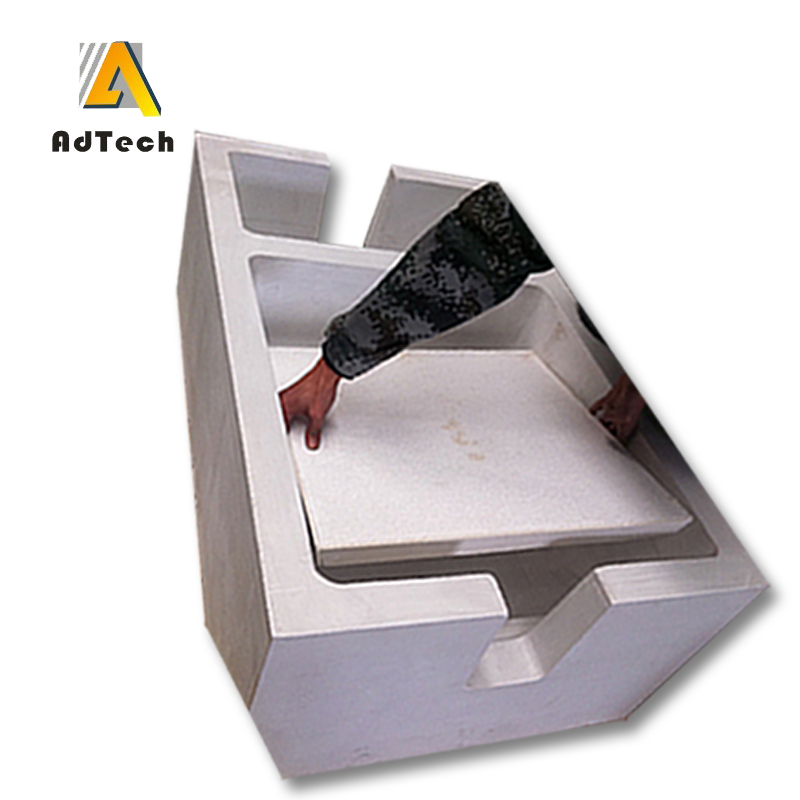

The filter plate shall be adapted to the square refractory filter box

The two are adapted to seal, so as to prevent the metal from flowing into the casting box from the gap without being filtered, and also avoid floating in the aluminum water due to the excessively light weight of the foam filter plate.

Preheating before use

Preheat to remove moisture and facilitate initial transient filtration.

Preheating can be carried out using electrical or gas heating.

Under normal circumstances, it takes about 15 minutes.

During normal filtration, no slag is required to avoid knocking and vibrating the filter plate.

At the same time, the launder should be filled with aluminum water to avoid too much disturbance of the aluminum water.

After aluminium casting process, drain the metal in the flow cell and filter plate.

There is a vibrator abroad that is placed on the foam ceramic filter plate and shaken for one minute to shake off about 75% of the remaining liquid metal from the filter plate.

Finally clean the perimeter and remove the foam ceramic filter plate after solidification.