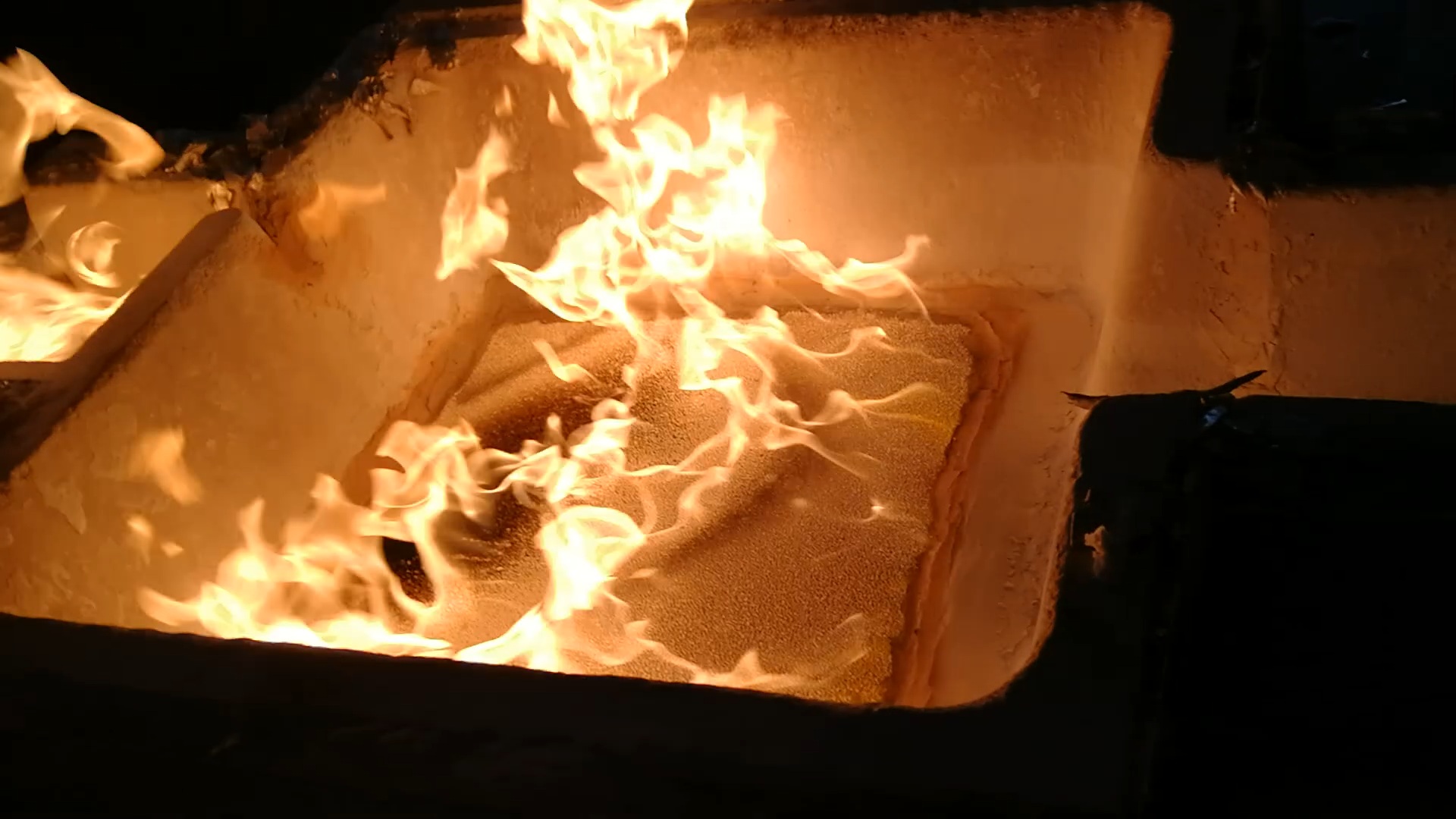

Use Ceramic Foundry Filter for aluminum alloy casting to purify the molten aluminium.

The four-square correction center distance automatic extrusion process is adopted to uniformly apply the slurry to the bubble skeleton of the carrier, and is baked and solidified at a high temperature of 1680 ° C.

Use Ceramic Foundry Filter and install in the aluminium casting filter box for the impurity filtration of aluminum alloy liquid, and it can meet the high-value-added and high-tech aluminum alloy precision casting of aviation and transportation.

Use Ceramic Foundry Filter Advantages:

1.Ceramic Foundry Filter adopts the principle of adsorption, which can effectively remove large inclusions in aluminum liquid and effectively adsorb fine inclusions of micron size. The filtration efficiency of the same mesh size is high;

2. No slag, effectively reduce the pollution of aluminum liquid;

3. Good thermal shock resistance and improved corrosion resistance to molten metal;

4. Automated assembly line production, three calibration procedures, accurate size, and more suitable for the aluminium casting filter box;

5. Ceramic Foundry Filter improves surface quality, improve product performance, and improve microstructure.