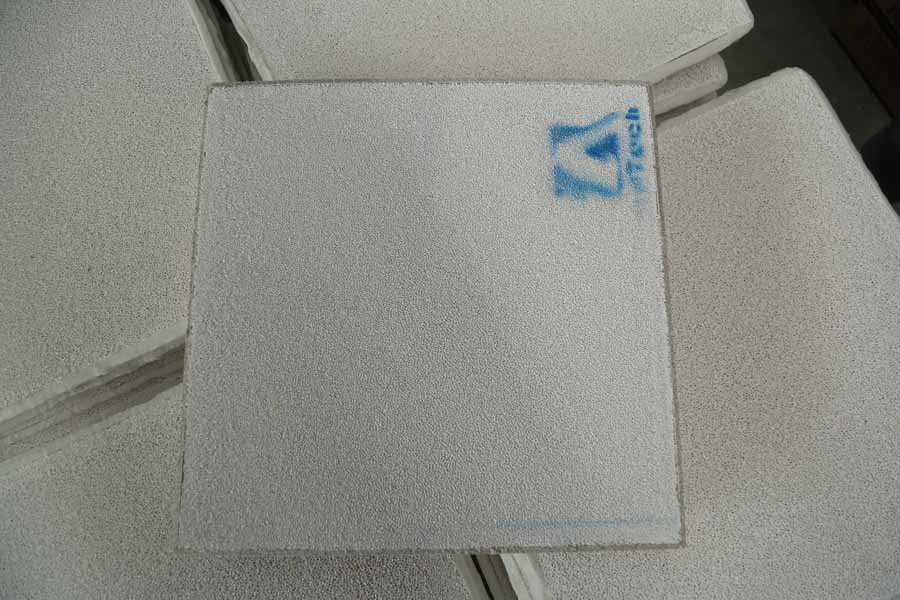

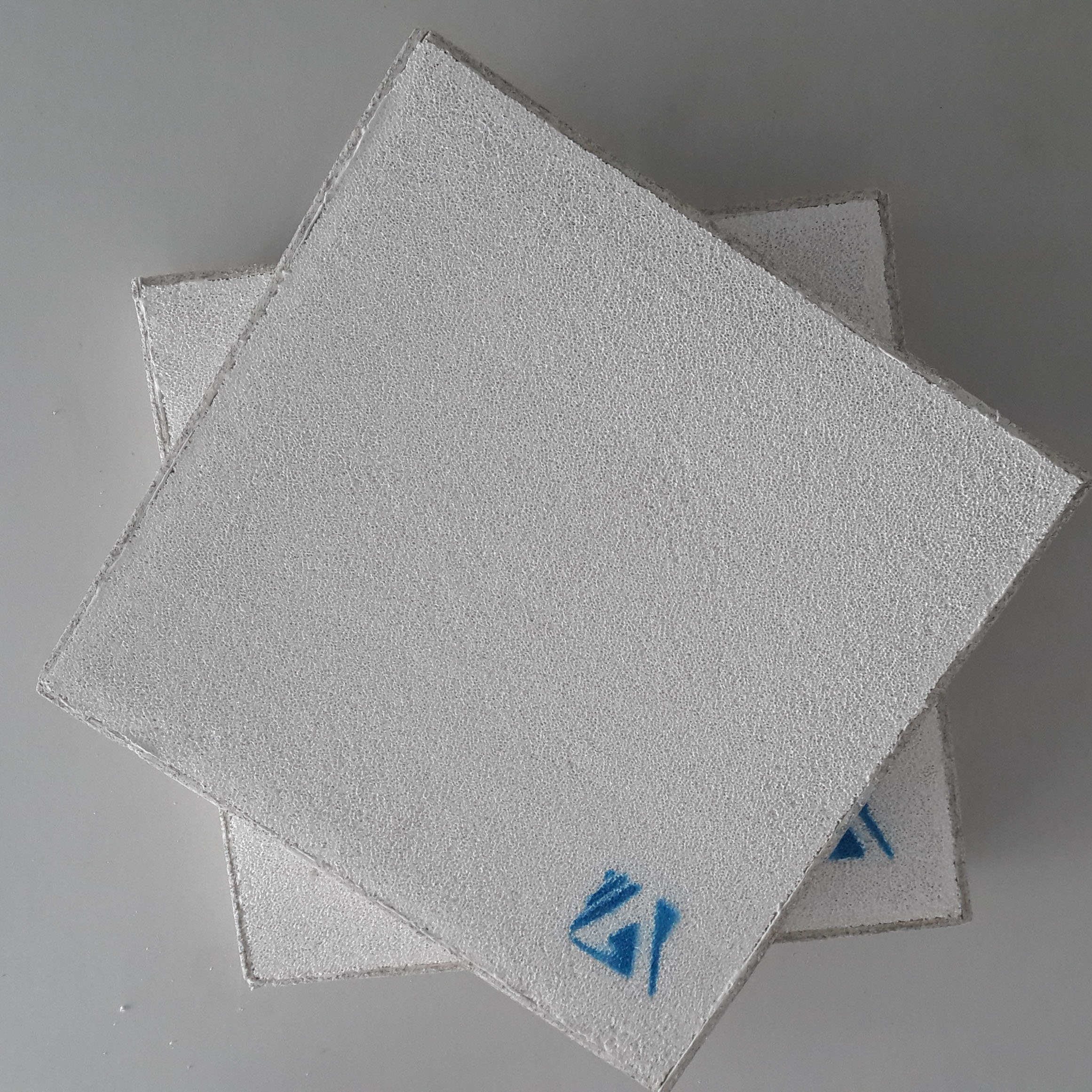

Use Alumina Ceramic Foam Filter by aluminium casting line can effectively remove all kinds of impurities in the aluminum liquid.

The sealing ceramic fiber gasket is affixed around the filter plate, which helps to seal the filter plate in the filter box and ensure that there is no aluminum liquid from Side out.

Here we introduce how to Use Alumina Ceramic Foam Filter

1. Inspect and clean debris on the surface of the filter box to keep the filter box clean and free from damage;

2. Use Alumina Ceramic Foam Filter into the filter box gently and press the sealing gasket around the filter plate to prevent the aluminum liquid from flowing or floating.

3. Evenly preheat the filter box and Alumina Ceramic Foam Filter so that they are close to the temperature of the aluminum liquid.

The preheating temperature of the filter plate is not lower than 460°C.

The expanded cotton is automatically sealed by the thermal expansion.

Use Alumina Ceramic Foam Filter to remove the adsorbed aluminium water. Parts, more conducive to help open the initial filter aperture opening, to prevent the thermal expansion and contraction to bring some plug to the filter plate.

Preheating can be electric or gas heating, normal heating 15-30 minutes.

4. Pay attention to observe the change of the aluminum hydraulic head when casting, and maintain the flow of normal demand aluminum liquid.

The normal initial pressure head is 100-150mm. When the aluminum liquid starts to pass,

The indenter will fall below 75-100mm, and then the indenter will slowly increase.

5. During the aluminium filtration process, avoid knocking and vibrating the filter plate.

At the same time, the flow tank should be filled with aluminum water to avoid the perturbation of the aluminum liquid.

6. After the filtration is completed, remove the filter plate in time and clean the filter box.