Top Level Ceramic Foam Filter

Top Level Ceramic Foam Filter from ADTECH keeps focusing on the manufacture of the metallurgical material.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

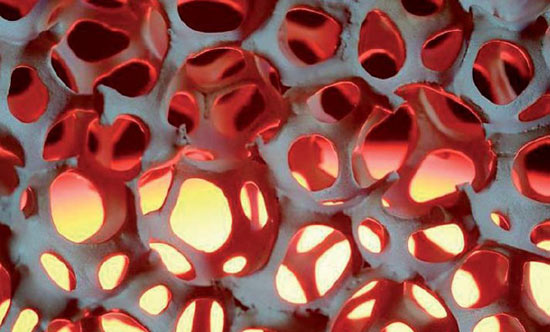

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

SALES@ADTECHAMM.COM

Top Level Ceramic Foam Filter use good portiforium foam and high purity ceramic as raw material, can removes non-metal solid mixture from molten aluminium and aluminium alloy fusant effectively in your aluminium casting industry.

Top Level Ceramic Foam Filter use good portiforium foam and high purity ceramic as raw material, can removes non-metal solid mixture from molten aluminium and aluminium alloy fusant effectively in your aluminium casting industry.

Top Level Ceramic Foam Filter Advantages

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

Top Level Ceramic Foam Filter Function

It is widely applied to the Foundry Foam Filters equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Ceramic Foam Filter transmittance

Transmittance refers to the effective filtration area of the foam ceramic filter plate product.

The higher the light transmittance, the less blind holes are, and the more effective the filter holes (potholes), the better the filtering effect.

The foam ceramic filter plate to be inspected is placed on a light box with a built-in 200W incandescent bulb.

The square transparent plastic plate with a uniform 5.0×5.0 mm square is used to measure the area of the large surface of the filter plate, so as to calculate the test.

The light transmittance of the filter plate is used to determine the light transmittance of the filter plate.

In this standard, the transmittance (through-hole ratio) of the filter plate is specified to be 95% or more.

Ceramic Foam Filter Porosity

Porosity is the percentage of the total volume of the cavities in the filter plate product to the total volume of the filter plate product.

Porosity determines the filtration capacity of the foam ceramic filter plate per unit volume.

The larger the porosity, the larger the filtration flow rate of the filter plate and the stronger the filtration capacity.

Ceramic Foam Filter Pore uniformity

Pore uniformity is used to describe the difference between the number of actual holes per 25.4 mm length in the filter plate product and the number of theoretically required holes.

The smaller the gap, the better the product quality, and the gap is too large, which will result in the ability of the filter plate product to reduce the impurity retention or the slow filtration rate of the melt, which can not meet the individual requirements of the user’s production.

The size of the pore uniformity mainly depends on the foam used in the production of the filter plate. The uniformity of the pores of the foam is good, and the uniformity of the pores of the filter plate is good, so the selection of the foam is extremely important.