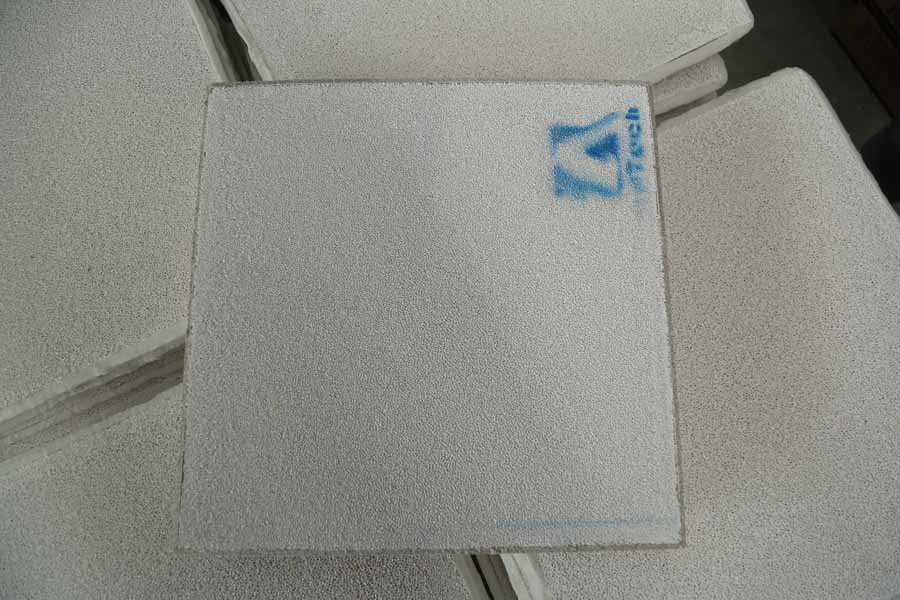

Sell Ceramic Foundry Filter which can improve the quality of finished products (foil, block, ingot, rod, profile, etc.) and meet the requirements of high purity cast metal. It reduces the scrap rate of the final product and improves the quality.

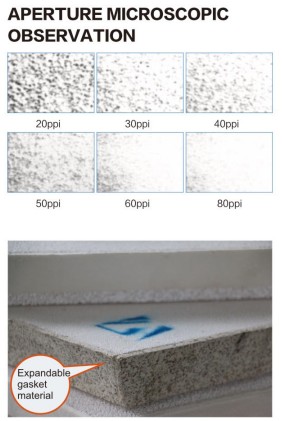

The filter usually uses a standard size in inches with a porosity of 10-60ppi (holes per inch).

The size of the filter depends on its porosity and is selected according to the filter capacity, casting time and the layout of the filter box. The choice of filter porosity depends on the specific alloy, casting temperature, metal contamination and the desired output quality.

Before casting, the filter must be fully preheated to ensure its normal operation.

Electric heating baking takes 1-2h, while natural gas baking takes 10-20min.

If the filter element is equipped with a permanent heating device, the filter can be reused. If the filter contains metal, the metal must be replaced for the next casting event.

The wetting behavior of aluminum and filtered Al2O3 and SiC foam ceramic filters were studied. Sell Ceramic Foundry Filter from sales@adtechamm.com

Nordic Aluminium tested the same CFF filter in a factory-scale filtration experiment.

Nordic Aluminium engineers said that the Adtech Ceramic foam filter has better contact with the metal, and the better wetting of the aluminum filter can improve the removal efficiency of impurities during the filtration process. And recommend Adtech Sell Ceramic Foundry Filter to other Nordic Aluminium Factory.

Wet inclusions are easier to remove.

Basic structure and classification of non-stick aluminum ceramic filter: The ceramic filter plate used for aluminum filtration is composed of a substrate, a surface film, a water outlet, a positioning seat, etc. The ceramic filter element for aluminum filtration is the core component of the CFF Unit.

It is a new type of porous functional ceramic material.

It is filled with criss-cross pores (about 1 to 10 microns in diameter). They are filtrate (water). The ceramic filter plate is composed of corundum, silicon carbide and other materials.