Sell Alumina Ceramic Foam Filter to all aluminum melting and casting processing industries, such as strip processing plants, foil processing plants, tubular bar processing plants and recycled aluminum ingot plants.

The quality of aluminum melt is very important, and has a great influence on its subsequent processing performance and the quality of the final product. Therefore, all countries in the world are very fond of purified aluminum melt.

During the melting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-melted state. It is easily oxidized, easily reacts with water vapor to absorb hydrogen, and easily forms various forms of non-metallic slag (such as furnace) lining garbage and flux. In chlorine). Compounds, carbides, etc.), coarse intermetallic particles, etc.

Sell Alumina Ceramic Foam Filter by ADTECH through sales@adtechamm.com, it has been focusing on the manufacture of metallurgical materials.

ADTECH is one of the followers of international companies, focusing on manufacturing metallurgical materials.

1. Ceramic foam filter

2. Degassing device

3. Filter element

4. Hot Top Casting Series

5. Die casting nozzle

6. Flux series

7. Other metallurgical materials

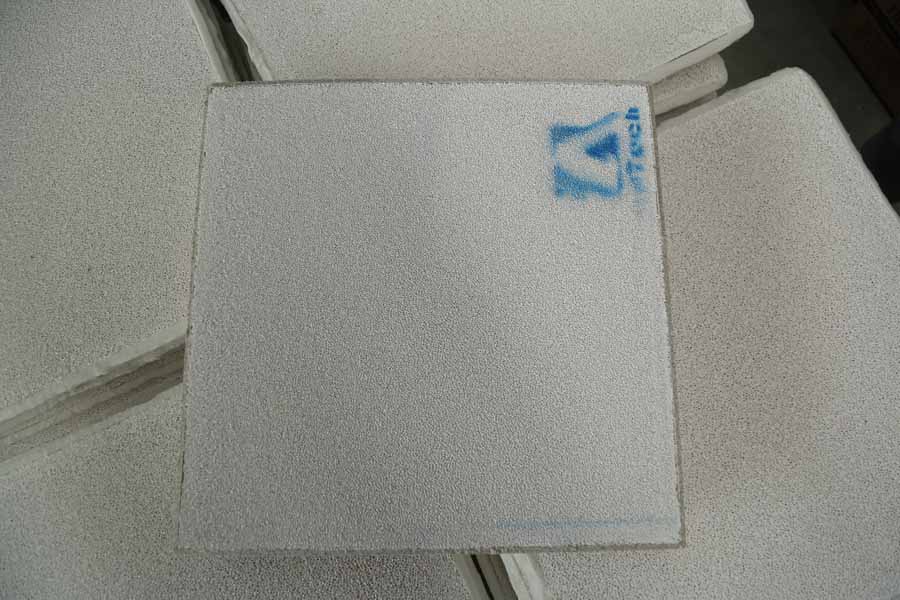

Alumina Ceramic Foam Filter adopts a three-dimensional network structure. It uses organic bubbles connected to the voids as the carrier and is immersed in the thixotropic alumina material slurry. The square-compensated center distance automatic extrusion technology is used to uniformly coat the slurry on the carrier. The foam is formed by firing and curing at a high temperature of 1180°C.

Features of aluminum casting filter

Filtration technology has been used to remove inclusions in molten aluminum for more than 30 years.

After successful production practice, it quickly replaced glass filters, microporous ceramic tubes, alumina balls and other filter carriers.

Advantages of ceramic foam filter

The filter adopts the adsorption principle, which can effectively remove the large inclusions in the molten aluminum and effectively adsorb the fine inclusions.

There is no debris, effectively reducing the pollution of molten aluminum.

Excellent thermal shock resistance, improve the corrosion resistance of molten metal.

Automatic production, 3 calibration procedures, accurate dimensions, and close installation of the bowl.

Improve the appearance and performance of the surface and purify molten aluminum.

Malaysia Aluminum Company has always maintained a high evaluation of Adtech Alumina Ceramic Foam Filter and achieved a long-term stable supply-demand relationship, and recommended this product to other aluminum factories.

The melting and casting plant of Southwest Aluminum (Group) Co., Ltd. successfully trial-produced a 6XXX alloy round bar. This is the work policy of the Southwest Aluminum melting and casting plant to promote the transfer of factory capacity. Combining the characteristics of domestic tools, it selectively adjusts the degree of automatic casting production. High equipment functions, compared with the alloy production experience, successfully produced a model of new alloys and new specifications.