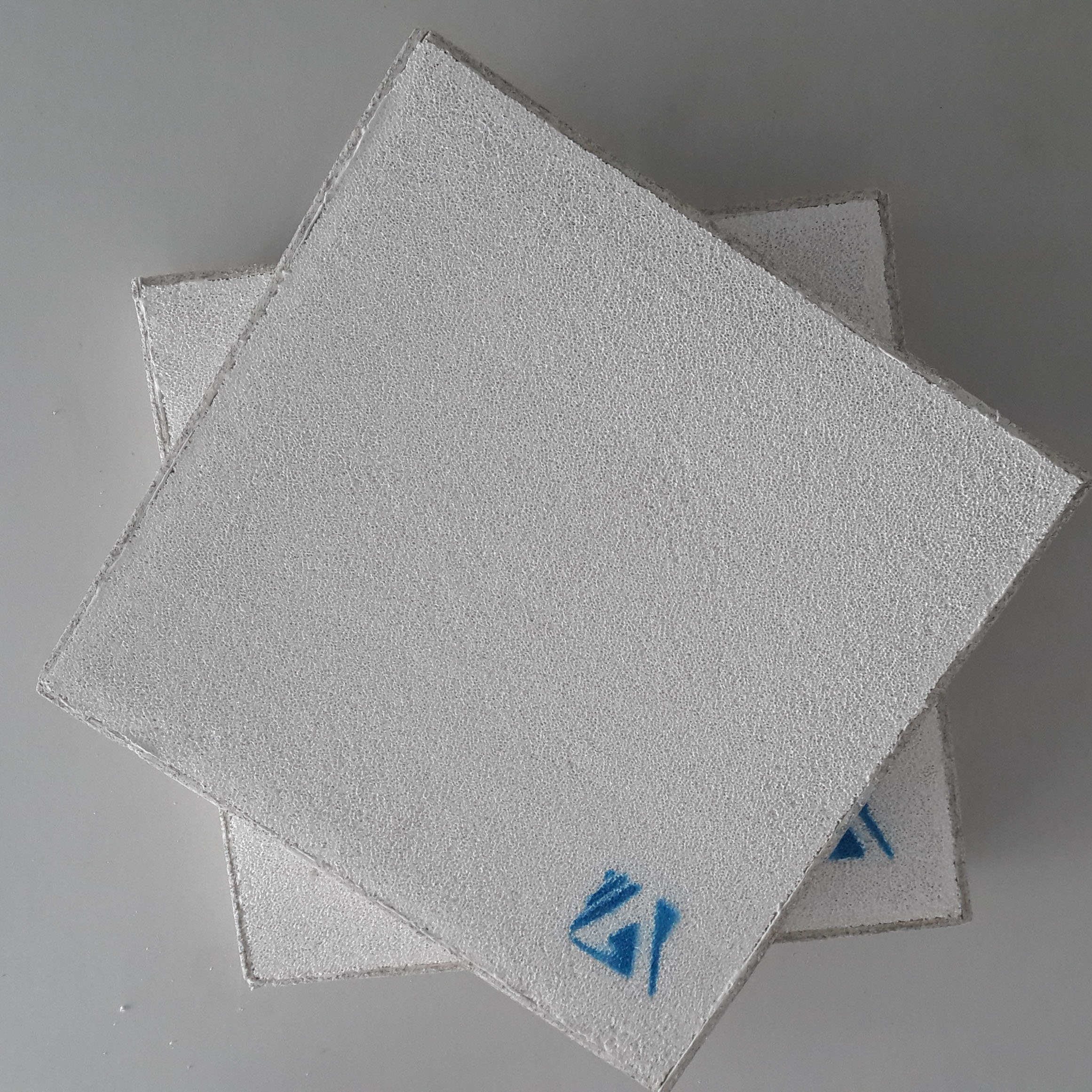

Selee Ceramic Foam Filter is the most widely used filter in the field of aluminum melt filtration. The advantages are high porosity, high filtration efficiency, easy replacement, low cost, strong adaptability, and can also be separated by filtering solid inclusions in liquid inclusions; disadvantages are low high temperature strength and short life (mostly for one-time use) The amount of filtration is small.

The aluminum cast ceramic filter can remove oxides on the aluminum surface, thereby improving the casting quality. Today, more and more aluminum sheet and aluminum foil manufacturers are using these filters.

Selee Ceramic Foam Filter is mainly used to filter aluminum and alloys in foundries and foundries. Due to its excellent resistance to corrosion and corrosion by molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow. Therefore, the filtered metal is significantly cleaner and the metal can produce higher quality castings. Fewer waste products and fewer inclusion defects, all of which help increase profits.

The density of aluminum is very small, only 2.7 g/cm³. Although it is relatively soft, it can be made into various aluminum alloys, such as hard aluminum, super-hard aluminum, rust-proof aluminum, cast aluminum, etc.

These aluminum alloys are widely used in manufacturing industries such as airplanes, automobiles, trains, and ships.

The conductivity of aluminum is second only to silver, copper and gold. Although its conductivity is only 2/3 of copper, its density is only 1/3 of copper. Therefore, the quality of aluminum wire is only half that of copper wire for the same amount of electricity. . The oxide film on the aluminum surface not only has the ability to resist corrosion, but also has a certain degree of insulation. Therefore, aluminum has a wide range of uses in the electrical appliance manufacturing industry, the wire and cable industry, and the radio industry.

Rusal Aluminum said that Adtech Ceramic Foam Filter has better performance than Selee. Engineers are thinking of recommending Adtech to aluminum casting plants in Russia.

Rusal Aluminum is using Adtech Ceramic Foam Filter to implement the following procedures to meet the total filtration capacity of the aluminum liquid and the cleanliness of the aluminum liquid.

1. Clean the filter box.

2. Gently put the filter in the filter box, and then press the gasket around the filter to prevent molten aluminum from flowing out of the side.

3. Even if the filter box and filter plate are preheated, they must be close to the temperature of the molten aluminum casting.

4. Observe the change of the liquid aluminum hydraulic head, the normal initial pressure head is 75-150 mm. When the alumina liquid starts to pass, the indenter will decrease below 25 mm, and then the indenter will gradually increase.

5. After filtering, remove the filter plate in time and clean the filter box.