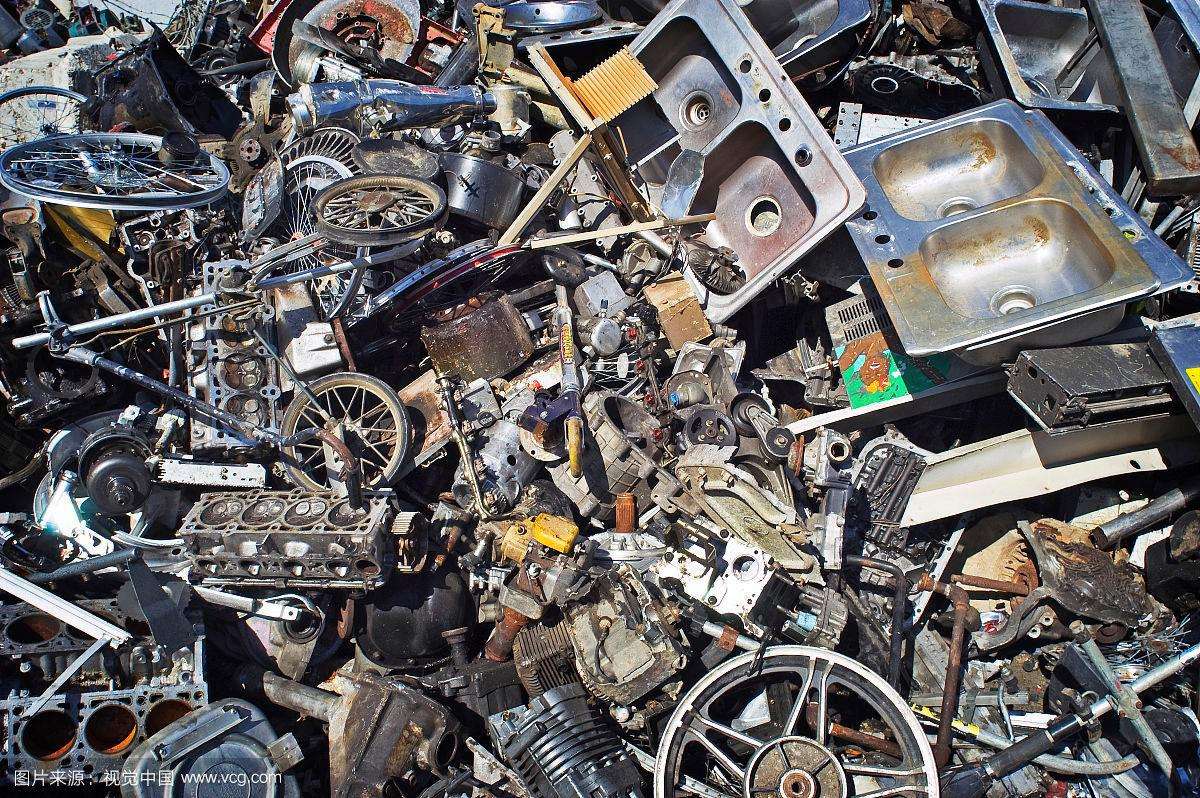

Scrap aluminum recycling

Scrap aluminum often contains organic non-metallic impurities such as paints, oils, plastics, and rubber.

Before returning to the furnace for smelting, it must be removed.

For wire scrap aluminum, measures such as mechanical grinding or shear stripping, heating stripping, and chemical stripping can generally be used.

At present, domestic companies often use high-temperature ablation to remove insulators. During the ablation process, a large amount of undesirable gases will be generated, which will seriously pollute the air.

If a combination of low-temperature baking and mechanical peeling is used, the insulator is softened first by thermal energy, the mechanical strength is reduced, and then peeled off by mechanical rubbing, which can not only achieve the purpose of purification, but also recover the insulator material.

The coatings, oil stains and other contaminants on the surface of waste aluminum utensils can be cleaned with organic solvents. If they still cannot be removed, the paint stripping furnace should be used to remove the paint.

The higher temperature of the paint stripping furnace should not exceed 566℃, as long as the waste material stays in the furnace for a sufficient time, the general oils and coatings can be removed.

For aluminum foil paper, it is difficult to effectively separate the aluminum foil layer and the paper fiber layer using ordinary waste paper pulping equipment. The effective separation method is to first heat the aluminum foil paper in an aqueous solution, pressurize it, and then quickly discharge it to a low pressure environment to reduce pressure. , And mechanical stirring. This separation method can recover both fiber pulp and aluminum foil.

The liquefaction separation of scrap aluminum recycling is the future development direction of recycling metal aluminum. It combines the pretreatment of scrap aluminum scrap with remelting and casting, which not only shortens the process flow, but also avoids air pollution to a greater extent, and makes the net metal The recovery rate is greatly improved.

There is a filter that allows gas particles to pass through. In the liquefaction layer, aluminum precipitates at the bottom, and organic materials such as paint attached to the waste aluminum are decomposed into gas, tar, and solid char at 450°C and then pass through the oxidation device inside the separator. Completely burned.

The waste is stirred by the rotating drum and mixed with the dissolving liquid in the silo. The impurities such as sand and gravel are separated into the sand and gravel separation area. The dissolve carried by the waste passes through the recovery propeller and returns to the liquefaction silo.

According to the preparation and quality status of scrap aluminum materials, and according to the technical requirements of recycled products, the ingredients are used and the amount of various materials is calculated.

Ingredients should consider the degree of oxidative burning loss of metal. The oxidative burning loss of silicon and magnesium is greater than other alloying elements. The burning rate of various alloying elements should be determined in advance through experiments.

The physical specifications and surface cleanliness of the scrap aluminum material will directly affect the quality of the recycled finished product and the actual yield of the metal. Waste aluminum that is not cleaned by oil removal can have up to 20% of the effective ingredients into the slag.

Deformable aluminum alloys that can be produced from waste aluminum alloys for regenerated deformed aluminum alloys, mainly producing 3105 alloys. In order to ensure that the chemical composition of the alloy material meets the technical requirements and process requirements of pressure processing, a part of primary aluminum ingot should be added if necessary.

Only a small part of scrap aluminum is regenerated into deformed aluminum alloys, and about a quarter of them are regenerated into deoxidizers for steelmaking, most of which are used to regenerate aluminum alloys for casting. The die-cast aluminum alloys A380 and ADC10 widely used in the United States, Japan and other countries are basically recycled from scrap aluminum.

[…] Grain refinement In order to ensure that the aluminum alloy ingot that meets the standard is obtained, in the later stage of smelting, grain refinement is required, […]