Rusal Alumina Porous Filter SPECIFICATIONS

Rusal Alumina Porous Filter USE

For filtering melt Aluninium and its alloys.

Rusal Alumina Porous Filter MATERIALS

Rusal Alumina Porous Filter be bonded phosphate (sintering process), high purity aluminia or quartz, resist erosive and chemical attack and are not soluble in molten aluminum at a temperature of 800 ℃ or less. The filter is strong enough to withstand various processes, so that during transportation it will not get damaged in normal operational use. It does not have ceramic particles or powder (snowing). It is with self-expanding gasket or silicate fiber gasket at the periphery.

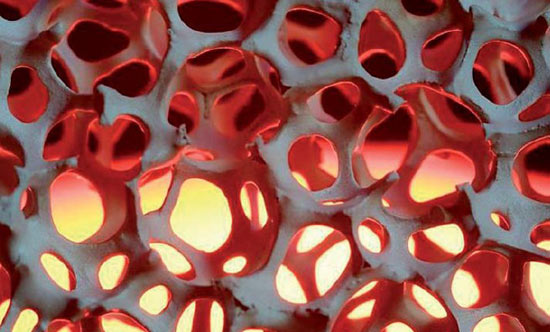

Ceramic foam filters have open, clean voids within a three-dimensional network.

The filters were designed to collect non-metallic sediments from liquid aluminum alloys.

The filter is based on silicon carbide (SiC) and aluminum (Al2O3).

The use of SiC and special aluminum oxides allows for a stable balance during casting of liquid metal, and also provides resistance to thermal shock.

Silicon Ceramic Foam Filter,10-50Ppi Alumina Ceramic Foam Filter, and Aluminum Casting Filtration are a ceramic product with a complex labyrinth of interconnected pores.

The skeleton of the products is determined by polyurethane foam, which is impregnated with liquid ceramics, followed by annealing.

According to their purpose, depending on the formulation of ceramics, the filters are divided into products for filtering cast iron, steel, aluminum alloys and other non-ferrous metals. Depending on the density of the polyurethane foam used, the products are produced in different porosities (ppi – pore number per square inch).