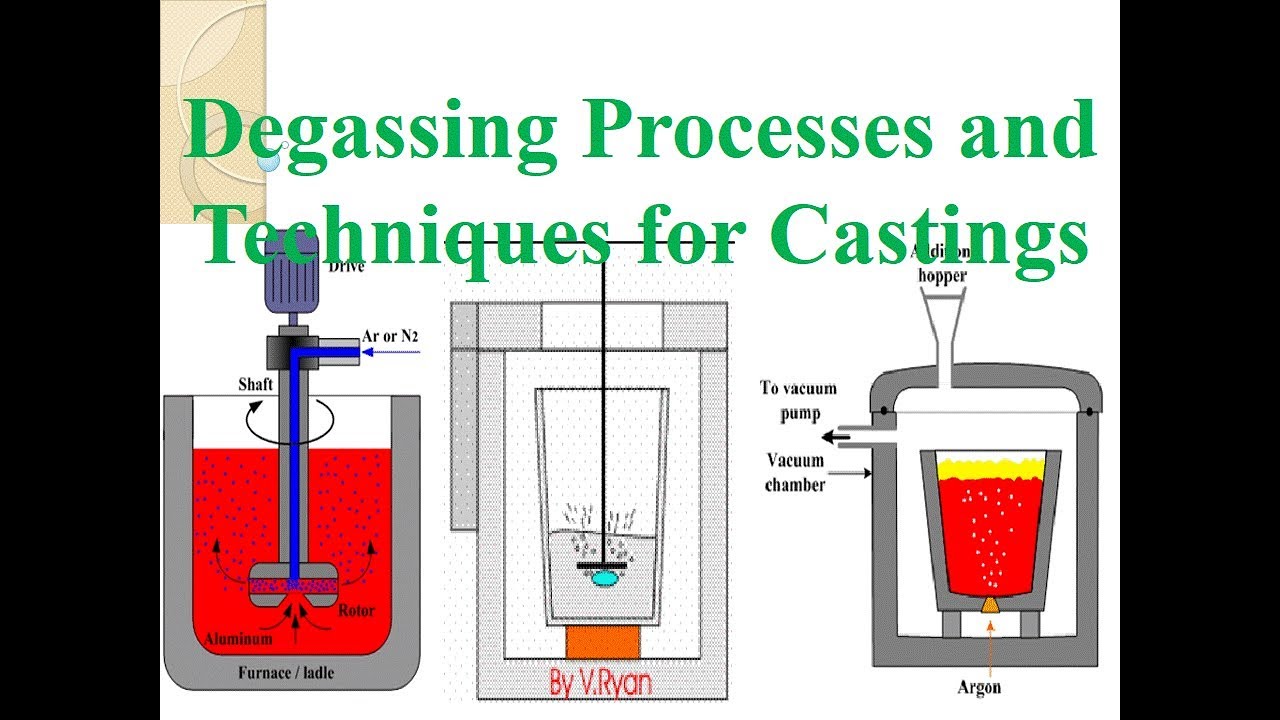

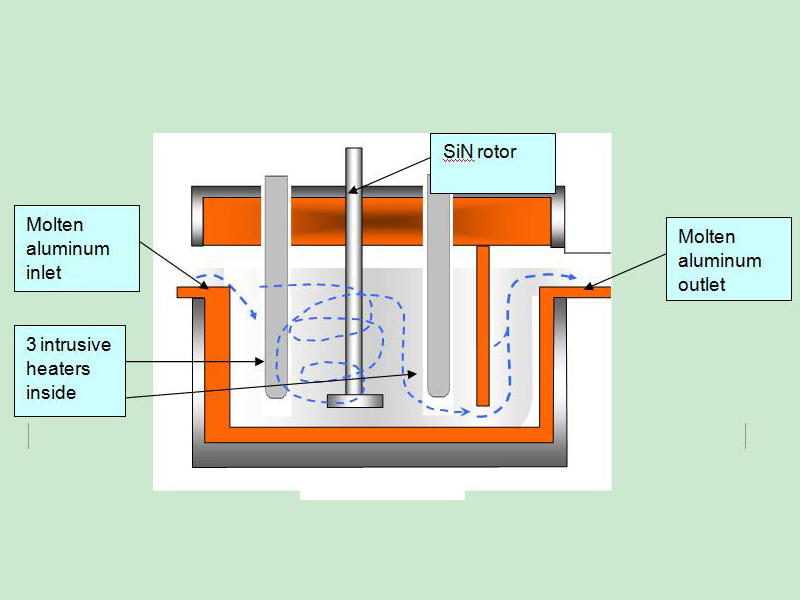

Rotors Degassing Machine is mainly used for the purification of liquid aluminum. It is the purification process of liquid aluminum alloy and the main method to improve the comprehensive performance of aluminum alloy.

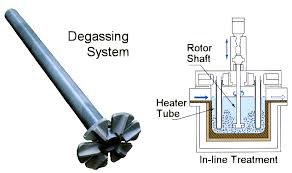

In the purification treatment process, the method of mixing the purification gas and the solvent and using the rotating spray of the silicon nitride rotor to the aluminum melt for purification treatment is currently the internationally advanced treatment method.

Aluminum alloy is superior to zinc alloy in many aspects, especially in terms of performance. In addition, its casting performance, mechanical properties and rigidity are higher than zinc alloy, and the precision of die castings is high, and the cutting allowance is small, so aluminum and aluminum alloy The development of die casting is extremely rapid.

The melting process and quality control of aluminum alloy materials are the first step in the entire melting and casting process. Rotors Degassing Machine is one of the important equipment in the aluminum alloy melting and casting process. How to ensure the stability and reliability of the smelting process during the production process and the effective monitoring of process quality are crucial.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

The liquid impurities in the aluminum alloy liquid are mainly chloride salts generated in situ. The chloride salt can be in a solid state or a molten state. Once formed, it is very difficult to remove from molten aluminum.

Chlorine and aluminum can combine to form AlCl3 at about 178ºC. If there is no magnesium in the molten aluminum, it will quickly vaporize and escape from the molten aluminum.

If the molten aluminum contains more than 0.2wt% of magnesium, AlCl3 will react with magnesium to form MgCl2. If MgCl2 enters the casting, it is a very harmful impurity.

Similarly, the sodium, calcium, lithium and strontium present in the aluminum liquid will also react with AlCl3 to form the corresponding chloride salt.

The pure substances of these chloride salts are generally solid at the smelting temperature, and form a liquid mixture after forming a eutectic system with magnesium chloride.

It is a very difficult challenge to remove these molten chloride salt mixtures from molten aluminum.

Because even with a metal filter, it is impossible to separate two immiscible liquids.

Due to the low density and small particle size of this molten chlorine salt, it will not precipitate in molten aluminum.

When sodium chloride-based salt flux is used in the slagging process, it will cause the compound reaction of the flux and the formation of liquid-phase slag-containing fragments.

It is very difficult to scrape off these substances. They are easily combined with oxides and slag. The density of the formed aggregate is very similar to that of the molten aluminum.