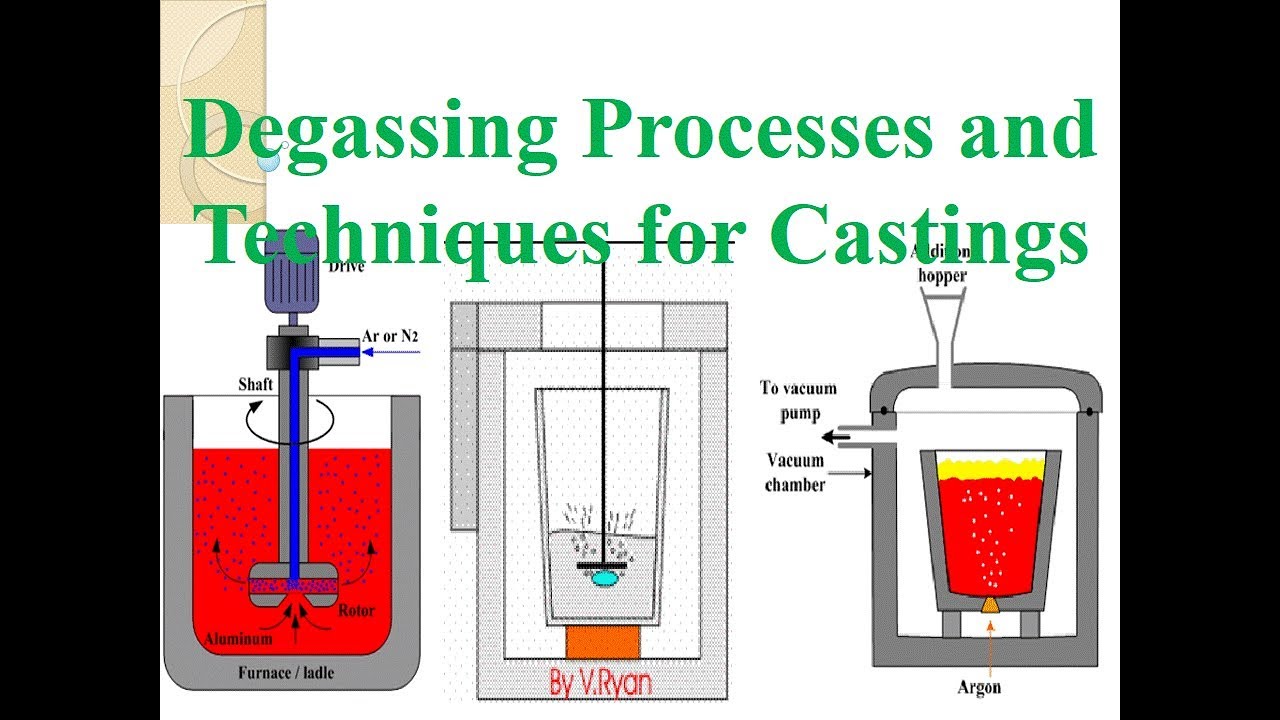

Rotary Degassing Equipment is carried out between the casting (or metal holding) furnace and the casting machine. Such a metallurgical launder can have a slight inclination from the casting furnace to the casting machine, and is suitable for the flow of molten metal from the casting furnace to the casting machine.

Impurities in molten aluminum

The impurities in the aluminum melt, in addition to the metal raw materials, during the melting process, the aluminum melt will also absorb impurities from the furnace lining, furnace gas, flux, charge and operating tools.

For the non-metallic inclusions in the aluminum melt, mainly refers to alumina. Its properties are dense and tough. Whether it is solid or liquid, it is easy to form a solid protective layer that adheres closely to the surface.

When the aluminum oxide film is impacted in the molten state, it is easy to become a fine film, causing the greatest damage. Although the density of alumina can reach 3~4g/cm, it is only 2.3~2.4g/cm at high temperature, which is almost the same as the density of aluminum solution.

Therefore, they are actually in suspension in the molten aluminum melt.

Once the oxidized slag has solidified, it is mixed into the casting strip.

Because it can neither be dissolved in aluminum alloy, nor can it form intermediate compounds with other elements.

It can only be distributed in the grain boundaries of the crystal grains in a solid state, thereby destroying the bonding force between the crystal grains.

Due to the presence of this oxide slag, the intercrystalline bonding force is destroyed.

It causes many hazards, reduces the process performance during pressure processing, and leads to delamination of the metal during processing, which leads to cracks.

The strength of aluminum products is unstable, and the elongation rate is greatly reduced. Especially under impact load or vibration load, ductile fracture will occur, thereby affecting the service life of the material.

At present, most aluminum alloy casting processes have been applied in Rotary Degassing Equipment. Practice has proved that different liquid temperatures in the online degassing device have different degassing effects.

Therefore, it is necessary to consider the liquid temperature requirements for the degassing effect of the online degassing device.

In addition, the escape of gas from the liquid in the crystallizer should also be considered.

Due to the low casting temperature, the gas in the mold is too late to emerge from the liquid surface, resulting in porosity and looseness, and may also cause quality defects such as slag and cold insulation.

The high casting temperature should not exceed the melting temperature.

Too high casting temperature will cause aluminum leakage at the beginning of casting.

Because the length of the transfer tool is different and the temperature drop of the liquid is also different, there are heating points on the pipeline, and the temperature of the liquid fluctuates greatly during the transfer process.

Therefore, the casting temperature should refer to the temperature of the liquid injected into the mold.

Generally, the casting temperature is 50°C to 70°C higher than the actual crystallization temperature of the alloy.

The transition zone of 1xxx and 3xxx series aluminum alloys in the casting machine is narrow, and the casting temperature should be higher. The transition zone of 2xxx and 7xxx series alloys is wider. The casting temperature should be lower than this temperature.