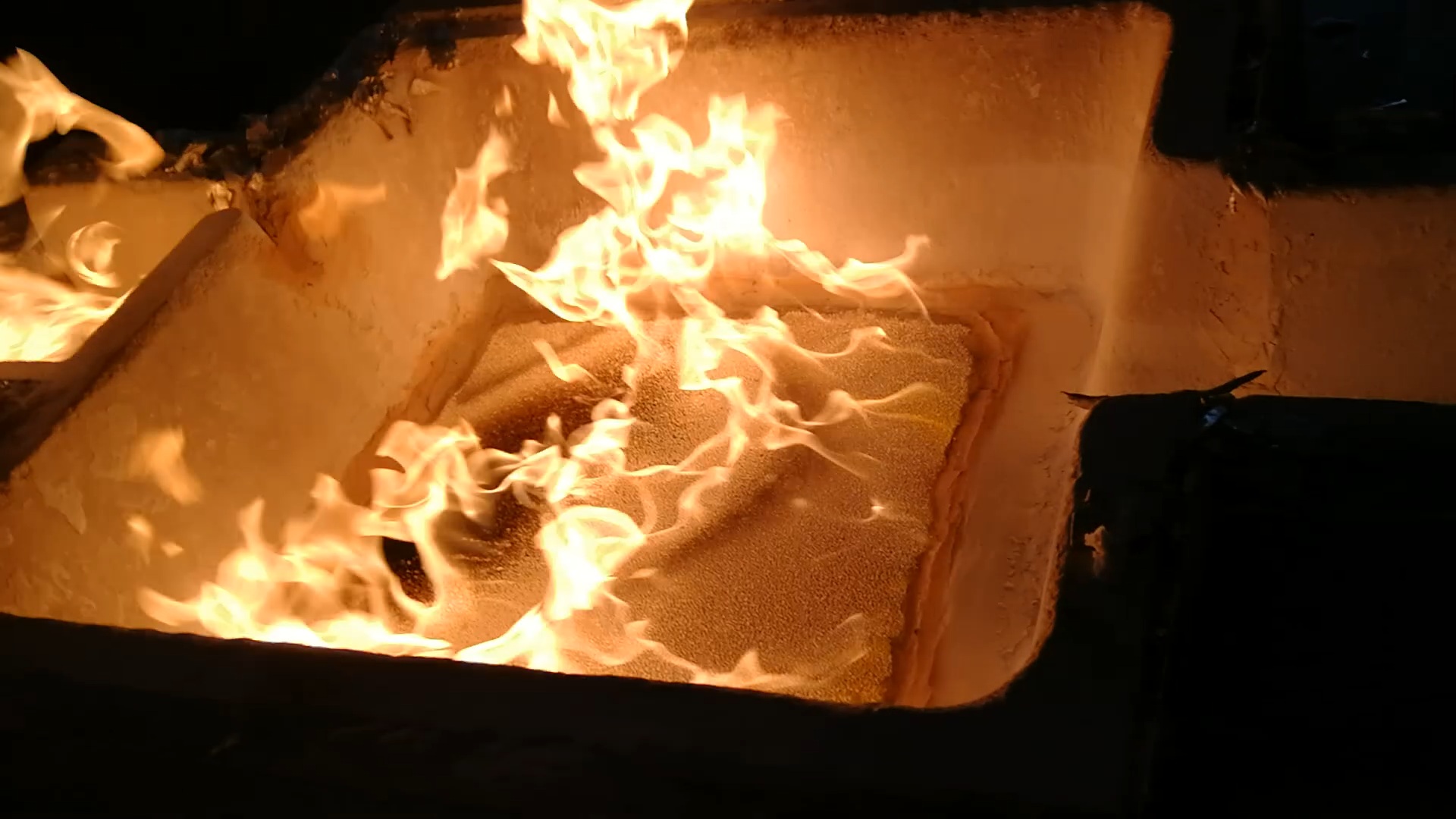

Reticulated Foam Filters are made by immersing polyurethane sponge in ceramic slurry, squeezing out the excess part, drying, and finally sintering at high temperature to form a three-dimensional porous ceramic material, which is a pipe with twists and turns interconnected with uneven thickness.

It is precisely this uneven tube wall that plays a key role in trapping small inclusions in the aluminum melt. This structure also increases the path through which the aluminum melt is in contact with the ceramic part of the filter, thereby increasing the probability of inclusion particles being attached.

The main purpose of using ceramic foam filters is to remove inclusions in the aluminum melt. Inclusions usually exist in three forms in the melt: metal oxides; foreign particles such as refractory scraps; particles introduced during melt processing.

Reticulated Foam Filters can not only effectively remove the bulk heterogeneous impurities in the molten aluminum, but also filter out small inclusions of a few microns that cannot be removed by traditional processes. Since the hydrogen atoms and other harmful ions in the aluminum liquid are often adsorbed on the inclusions, and the inclusions can become the core of bubble formation, so while filtering the inclusions, it can also reduce the harmful gases in the aluminum liquid.

The ceramic foam filter manufacturer will use a set of more complete measures to ensure the stability of the product, to ensure that the strength, through-hole rate, geometric size, appearance quality, physical and chemical properties of the final product meet the standards.

In production, in order to achieve a better filtering effect, the aluminum liquid upstream of the Reticulated Foam Filter must have a certain degree of cleanliness, that is, the upstream aluminum liquid can be treated with traditional gas dehydrogenation or flux treatment.

To remove inclusion particles above 30um, it is recommended to use multi-stage filtration technology and filter with different ppi filter combinations to achieve satisfactory results.

If the above measures are not used as a prerequisite, separate filtration and purification of aluminum alloy melts with high hydrogen and oxygen content, many non-metallic inclusions, and larger sizes, not only the filtration efficiency is low, but the filter is easy to block, resulting in increased costs and purification The effect will not be very good.

After taking the above measures, the hydrogen content in the alloy melt has been reduced to a very low level, and the size of the oxide inclusions in the melt has also been smaller.

Therefore, the use of Reticulated Foam Filters can effectively remove the fine and dispersed oxidation inclusions, thereby improving the filtration efficiency and reducing the cost of filtration and purification.

In addition, the filtered high-quality molten aluminum must be protected from secondary pollution, that is, there should be more stringent requirements for the refractory materials downstream of the filter box, and the surface oxide scale of the downstream molten aluminum must be protected.