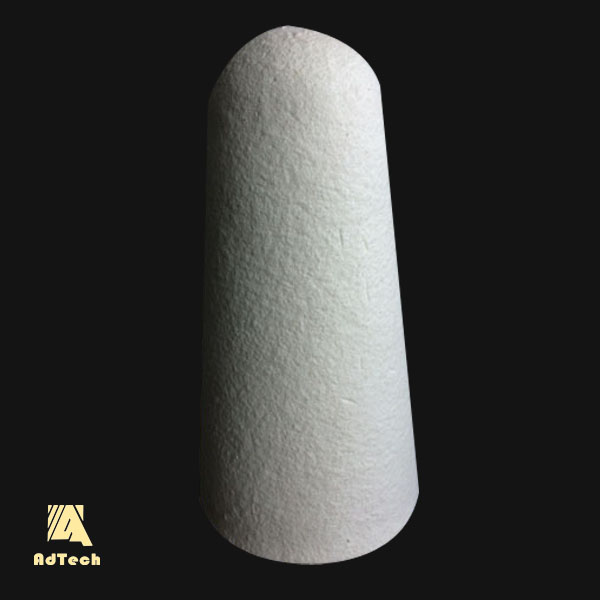

Refractory Cone Molded and Unshaped

Aluminosilicate refractory materials

Aluminosilicate refractories (alumina-silica refractories) are refractories made primarily from A12O3 and SiO2.

Depending on the amount of A12O3 content, such Refractory Cone are:

– semi-acidic (A12O3 content – from 14 to 28%);

– chamotte (A12O3 content – from 28 to 45%);

– high alumina (A12O3 content – from 45 to 95%).

Semi-acid refractories – aluminosilicate refractories with a mass fraction of A12O3 from 14 to 28%.

Their properties allow the use of such refractories only in insignificant areas of the lining of coke ovens and in some other steel units, but as fire insulation, this type of refractory has great prospects.

Refractory Cone refractory materials

1) Features:

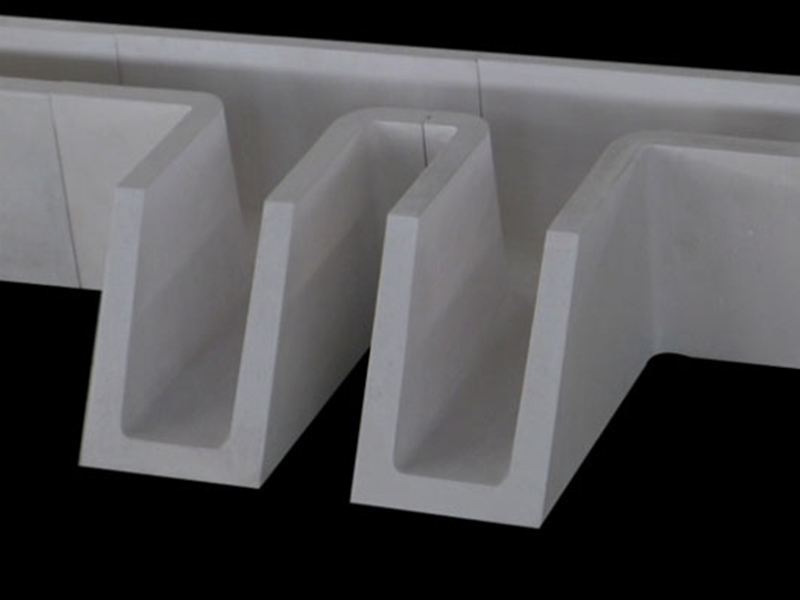

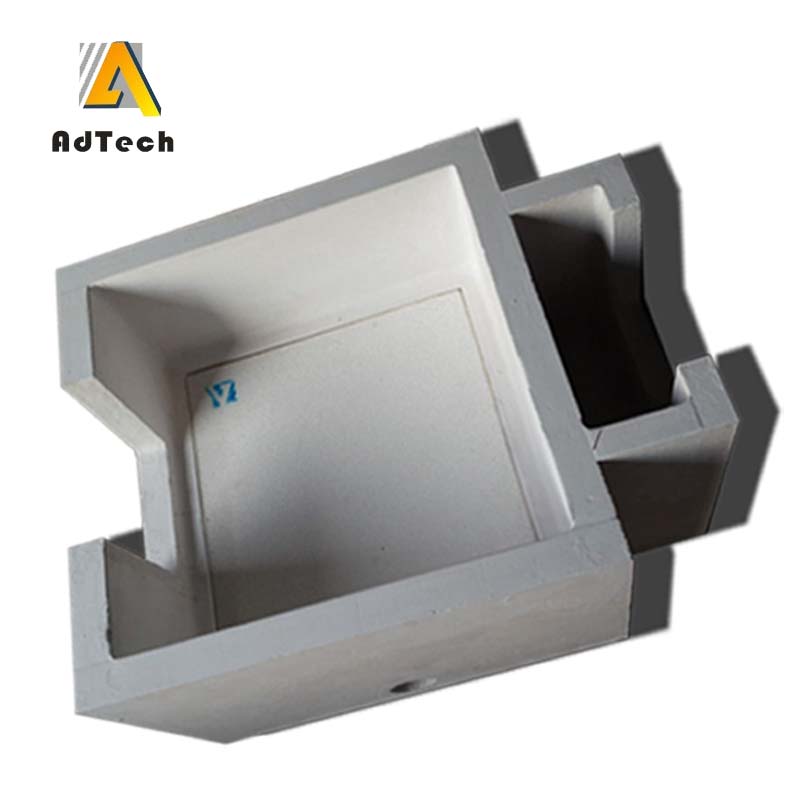

1. Silica aluminosilicate fiber cone is a kind of aluminosilicate fiber / ceramic fiber product, non-stick aluminum and non-slip.

2. Plastic is evenly distributed with good flexibility.

3. Tight Lock and stable flow control.

2) use

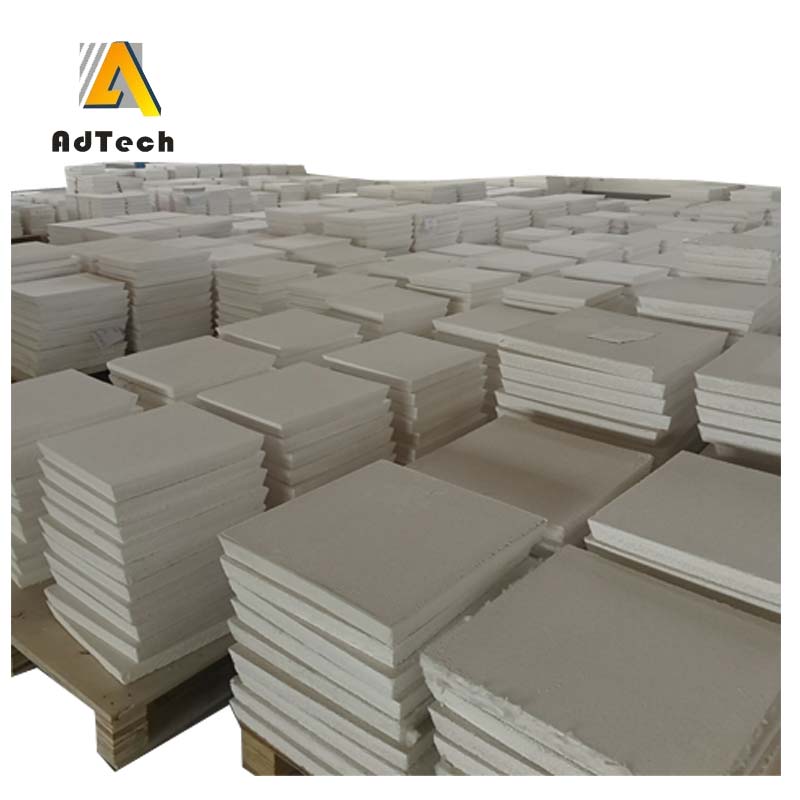

Alumina silicate fiber Refractory Cone made of high quality alumina; to control or block the flow of liquid aluminum for precision casting of aluminum and aluminum alloy.

3) TAP OUT CONE Performance(click it for the parameter)

1. Silica alumina cone made of ceramic fiber

2. Silica alumina cone has the properties of non-stick aluminum and non-coagulation; Moreover, plastid evenly distributes good elasticity, tight blocking, stable flow control

4) Dimensions

The length of the cone of silica fiber alumina 20-350 mm, usually conical; or made according to customer requirements.