1. Application of deep bed filtration equipment

Deep bed applications

a. Applied to batch and continuous production lines, replacing plate filtration, increasing filtration capacity, and ensuring stable product quality;

b. can reduce labor costs and cause excessive unnecessary energy loss (compared to plate filter);

c . foundries for large-scale production of thin materials, such as cans, foils, etc. (the final product is thinner aluminum foil);

Carbide, or relatively difficult aviation flat and round ingots;

More distinctive products (such as PS board, bright anode foil, etc.) and capacitor foil;

d. double zero aluminum foil material (0.006mm);

Henan Mingtai Technology uses deep beds to produce large slab ingot production line:

Henan Mingtai Technology uses deep bed to produce large slab ingot production line

2. Function of deep bed filter equipment

a. Principle of deep bed filtration

The aluminum liquid enters from the inlet of the deep bed equipment, and after being filtered by the filter bed (filter medium), the impurities in the aluminum liquid are filtered out, and the pure aluminum liquid flows out from the outlet of the deep bed.

Principle of deep bed filtration

b. Deep bed filtration accuracy

It is generally used for all alloys. According to the purpose of deep bed equipment, the way of laying the filter medium is different from the size of the filter medium. The range of filtration accuracy (impurity diameter) is: 5μm–30μm;

Filtration slag removal effect, the range of aluminum slag content is: ≤0.03mm²/kg aluminum ~ ≤0.008mm²/kg aluminum (detected by ABB off-line slag tester).

c. Amount of aluminum passing through the deep bed (T/H)

According to the different specifications and models of deep bed equipment and the laying method and size of the filter medium, the range of aluminum flow is 15-80T/H.

Note: Due to the characteristics of magnesium (Mg) element, when alloyed (Mg≥1%), the amount of aluminum passing through the deep bed will decrease accordingly.

d. Deep bed insulation performance

The average temperature of deep bed shell: ≤+65℃

Such as Henan Hongxinghua Aluminum Co., Ltd., EG-S-55T online deep bed

EG-S-55T Online deep bed

3. Advantages of deep bed

a For batch and continuous production lines, replace the plate filter, improve the filtration capacity, and ensure stable product quality;

b Reduce labor costs and cause excessive unnecessary energy loss (compared to plate filter equipment);

c Realize semi-automated production and comprehensively reduce production costs, that is, automatic tilting device.

Automatic tipping device

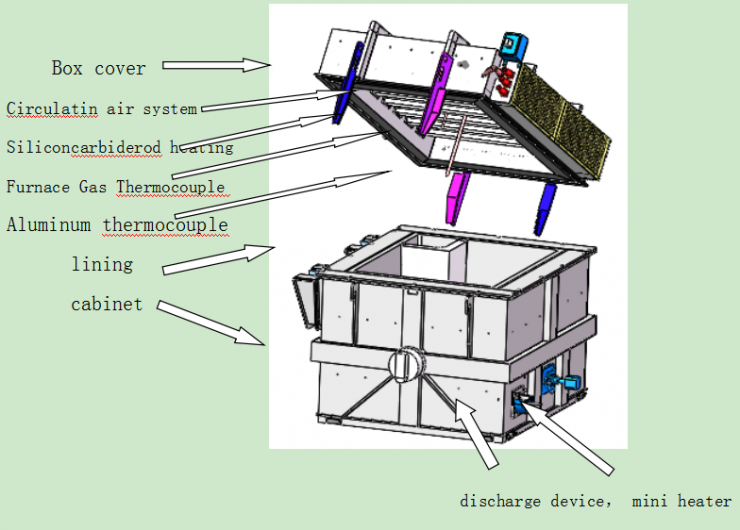

4. Deep bed equipment structure

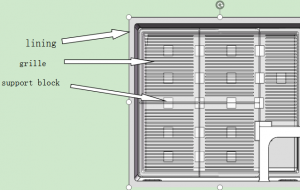

Deep bed equipment structure