Component Analysis for porous ceramic filter Devices

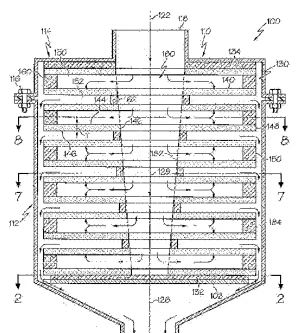

1 The filtering device according to claim 1, is characterized in that each of the radial flow areas has an axial width limited between the corresponding pair of the plurality of porous ceramic plates, wherein the axial width of at least one of the first group of radial flow areas is greater than the axial width of at least one of the second group of radial flow areas

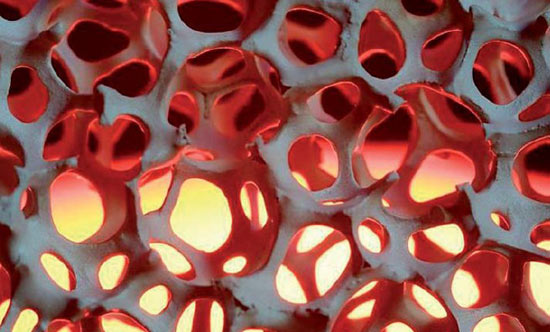

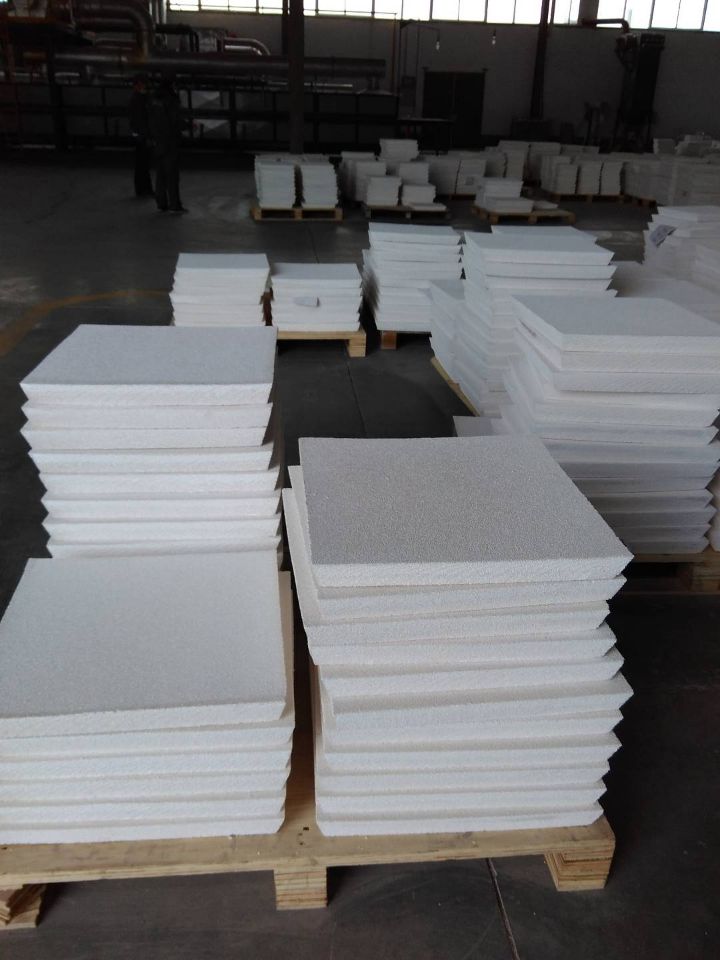

porous ceramic filter

2. The filtering device according to claim 1, is characterized in that: The first side of the plurality of porous ceramic plates has a corresponding filtering surface area that is successively larger than the previous one in the axial direction.

3. The filtering device according to claim 1, is characterized in that the central hole of the plurality of porous ceramic plates is successively smaller than the previous one in the axial direction.

4. The filtering device according to claim 1, is characterized in that the plurality of porous ceramic plates alternate between the first group of porous ceramic filters and the second group of porous ceramic plates in the axial direction, Wherein, each porous ceramic plate in the first group of porous ceramic plates comprises an outer circumference configured to be nested in the corresponding porous ceramic plate in the second group of porous ceramic plates. The filtering device according to claim 1, is characterized in that the plurality of porous ceramic plates alternates between the first group of porous ceramic plates and the second group of porous ceramic plates in the axial direction, Each porous ceramic plate in the first group of porous ceramic plates includes a central collar part, which is configured to be accepted in the central hole of the corresponding porous ceramic plate in the second group of porous ceramic plates.

5. A filtering device, including a filter stack, wherein the filter stack comprises a plurality of porous ceramic plates each including a central hole positioned along the central flow channel, and the plurality of porous ceramic plates are axially spaced from each other in the axial direction of the filtering device to define a plurality of axially spaced radial flow areas, The plurality of axially spaced radial flow areas alternate between the first group of radial flow areas open to the central flow channel and the second group of radial flow areas closed to the central flow channel in the axial direction, wherein the plurality of porous ceramic plates alternate between the first group of porous ceramic plates nested with the second group of porous ceramic plates, and wherein, Each of the plurality of porous ceramic plates includes a first side and a second side, wherein at least one of the sides defines a plurality of radial grooves, and the plurality of radial grooves are arranged in a radial array around the corresponding holes of the porous ceramic plate to increase the filtering surface area of the side with the radial grooves

6. The filtering device according to claim 14, is characterized in that: Each porous ceramic plate in the first group of porous ceramic plates comprises an outer edge configured to be nested in the corresponding porous ceramic plate in the second group of porous ceramic plates

7. The filtering device according to claim 14, is characterized in that each porous ceramic plate in the first group of porous ceramic plates comprises a central collar part, The central collar part is configured to be accepted in the central hole of the corresponding porous ceramic plate in the second group of porous ceramic plates