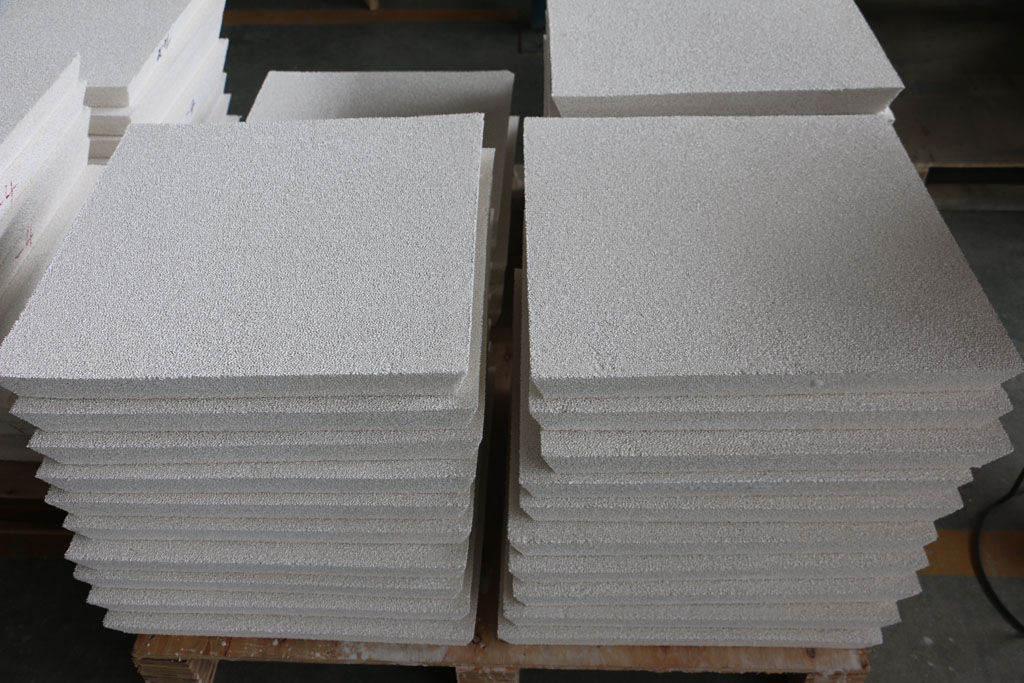

Porous Ceramic Filter Filtration is a ceramic with a porosity as high as 70% ~ 90%. It has a three-dimensional network structure. It is a new type of porous material that replaces the connected pore structure of metal.

The ceramic foam filter for aluminum separates the inclusions in the liquid casting alloy through three physical and chemical effects on the molten metal, so as to achieve the effect of purifying the molten metal.

Filter cake effect

The composite foam ceramic structure can effectively mechanically resist slag.

When the molten metal passes through the ceramic foam filter with complex structure, the filter medium is mechanically separated to filter out the inclusions larger than the pore size of the filter surface, and make it precipitate at the inflow end of the filtrate metal.

As the number of inclusions on the filter surface increases, a layer of “filter cake” will gradually form, which will further narrow the flow path of the molten metal. Therefore, the surface of the new filter medium can filter out finer inclusions.

Surface effect

When the molten metal flows through the ceramic body with complex structure, it is divided into many small streams, which increases the contact area and contact probability of the inclusions in the molten metal and the filter medium.

Because the surface of the filter is extremely small with concave and convex, the size of the concave block is about 1~10um, which has electrostatic adsorption and adhesion interception of inclusions.

Rectification effect

When the molten metal flows through the ceramic foam filter, it is divided into many small unit streams, the diameter of which is small, which makes the Reynolds number smaller, and the liquid flow tends to be laminar.

When the molten metal is in a laminar flow state, since the density of the molten metal is much greater than the density of the inclusions, the inclusions have enough time to float and be removed, that is, the ceramic foam filter can assist the flow channel to stop the slag.

Adopt Porous Ceramic Filter Filtration

According to the melting point of the alloy, select a filter of suitable material to avoid excessive temperature, which may damage the function of the filter and fail to achieve the filtering effect.

Choose the corresponding filter, the purification effect should meet the pouring requirements.

Try to use the upper limit of the casting temperature to increase the fluidity of the metal.

When the filter is placed horizontally under the cup or parting surface, the height of the casting should not exceed 20cm. It is best to rinse the metal liquid on the wall of the cup, not directly on the filter.

This filter must be handled gently. When not in use, place it in a dry and ventilated place to avoid moisture absorption affecting the strength of the filter.