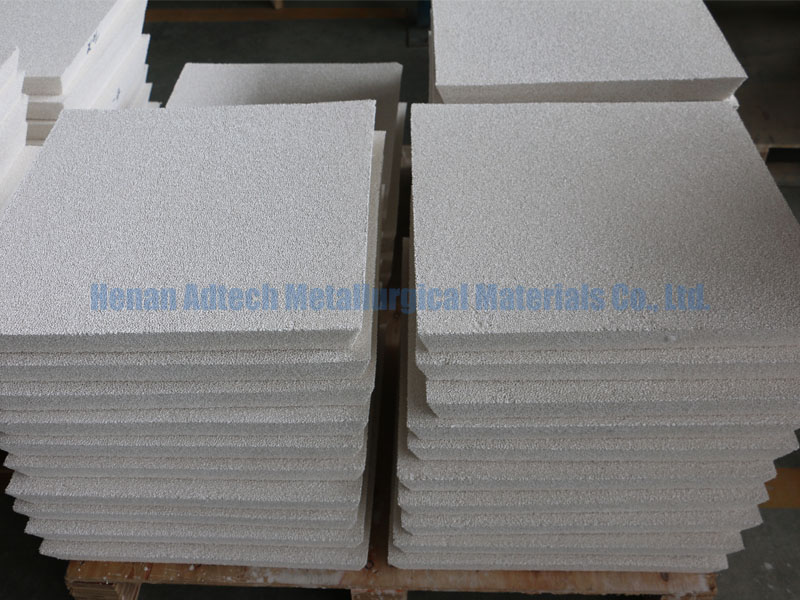

Porous Alumina Ceramic Foam Filter

Porous Alumina Ceramic Foam Filter plays a vital role in the metal casting and foundry industries, where they are used to filter out impurities in molten metal to improve the quality and performance of the end product.

Ceramic foam filters demand precision performance in extreme heat and harsh conditions, and have to meet the highest standards in terms of performance, durability and heat resistance.

This is where Technical Foam Services’ expertise and engineering know-how come to the fore.

As the recognised leader in engineering-based foam conversion, we supply products that are used in some of the most well-known foundries around the world for casting aluminium, steel, iron and copper.

Even the slightest non-metal impurities in molten metal can have a devastating effect on the performance and strength of finished metal goods.

This can result in end products failing to meet the necessary quality standards, which may prove extremely costly if they need to be recast or scrapped.

Porous Alumina Ceramic Foam Filter plays an essential role in removing these impurities and ensuring high-quality casting.

As a result, precision and accuracy in ceramic filters is paramount.

That’s why so many Aluminium casting Company customers choose Adtech Ceramic Foam Filter Services as their supplier – to ensure quality, durability and performance every time.

As renowned converters of high-grade polyurethane reticulated foam, Adtech China can produce ceramic filters in a wide range of thicknesses, pore sizes (20ppi to 80ppi) and composites to meet the needs of every metal casting process.

These range from slim castings for automotive and aerospace applications to robust ceramic foam filters, for casting iron or steel plant and machinery components.

Whatever the application, with Adtech China(www.adtechamm.com) you can be sure of the highest quality and superior performance every time.

Forging ahead in ceramic filter technology

As a leading engineering-based company, Adtech ceramic foam filter effectively remove non-metallic inclusions to improve performance in the end product and facilitate the fabrication processes in numerous ways.

1. Superior mechanical performance

With non-metallic elements removed from the molten metals, the finished product will provide improved strength and resistance to fatigue and wear.

This is vital in all applications, but particularly in situations where metal fatigue could result in serious human injury, such as in the automotive or aerospace sectors.

2. Improved appearance

The purer the molten metal, the smoother the surface that is achieved, resulting in more aesthetically pleasing and mould-resistant goods.

Ceramic filtration also prevents gas bubbles from forming.

3. Effective machining

In general, non-metallic elements are denser and harder, resulting in a reduced lifespan for tooling and machining equipment.

4. A melting pot of ideas

Having been involved in the conversion of high-quality ceramic foam filters since 2012, Technical Foam Services has a wealth of knowledge and experience in this field.

[…] liquid aluminum permeability to ensure smooth filtration during the production process. Therefore, Porous Alumina Ceramic Foam Filter should have a small thermal expansion coefficient without cracking when heated. It does not absorb […]