Overview of refractory materials

Refractory is an inorganic non-metallic material with a refractoriness of not less than 1580 ° C. It is the basic material for high temperature technology.

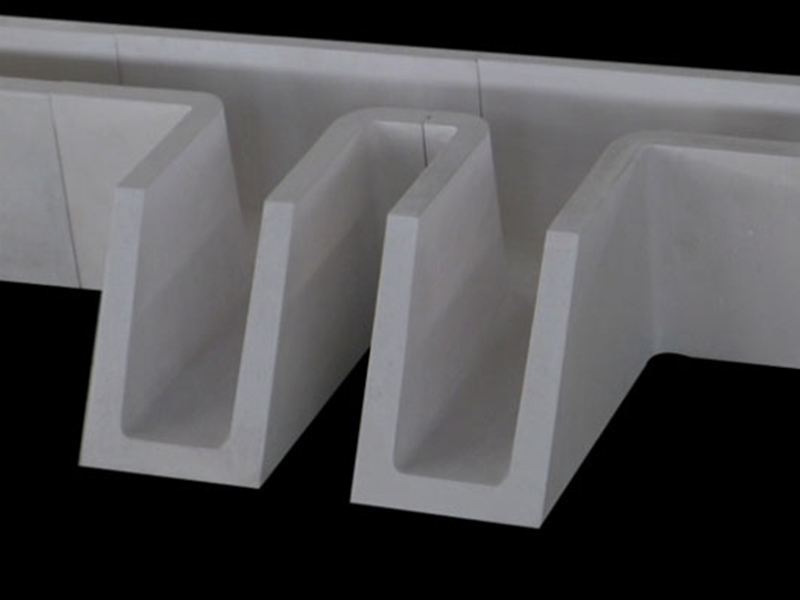

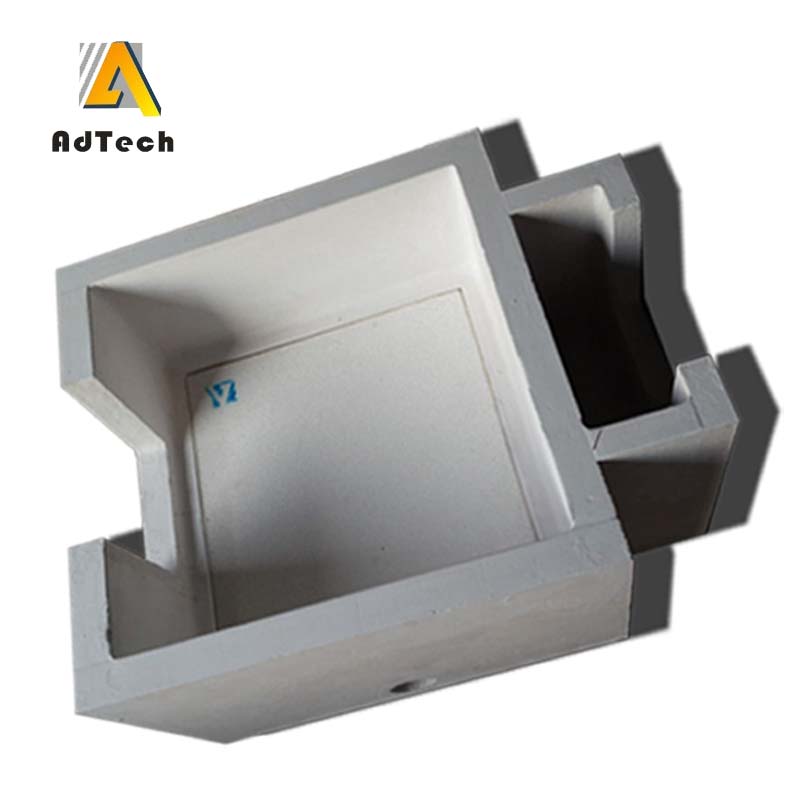

It is a structural material for thermal equipment such as masonry furnaces, and is also a functional material for manufacturing certain high-temperature containers and components or for special functions.

The successful use of refractory materials under high temperature must have good microstructure, thermal properties, mechanical properties and performance.

With high refractoriness, load softening temperature, thermal shock resistance and chemical resistance, it can withstand various physical and chemical changes and mechanical effects to meet the requirements of thermal equipment and components.

Refractory materials are generally manufactured by processing natural stone, such as bauxite, silica, magnesite and other raw materials, called ordinary refractory materials.

At present, high-quality refractory raw materials and synthetic materials are increasing, and advanced refractory materials are developed.

Special refractories made of pure oxides and refractory compounds have also been greatly developed.

These refractories have been widely used in industries such as metallurgy, building materials, petrochemicals, machinery and atomic energy, and have achieved good economic results.

Refractory materials are mainly used in the metallurgical industry, and their consumption accounts for 60% to 70% of the total.

Therefore, refractory materials are an important foundation for the development of the metallurgical industry and have a strategic position. The development of refractory materials is interdependent and mutually reinforcing with the technological advancement of the metallurgical industry.