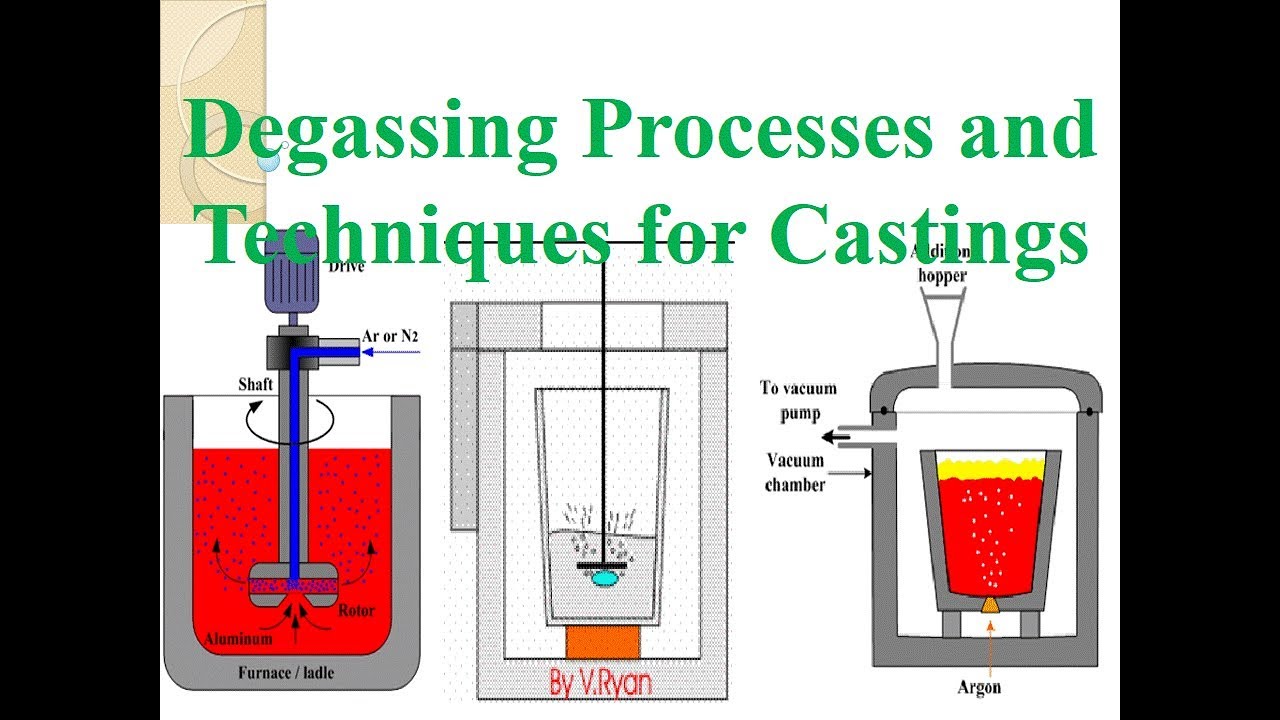

Online Degasser achieves stable operation by changing the power transmission mode of the rotor, so that the rotor can run at high speed, thereby removing the H. in the molten aluminum.

Currently, it is usually 300 to 450 rpm, and the maximum is 600 rpm.

After changing to the bottom gearbox, the length of the drive shaft is shortened, the length of the rotating shaft is shortened, the rigidity of the drive shaft is increased, and the swing of the turntable is reduced, so that the maximum speed can reach 900rpm and run stably.

The degassing efficiency has also been further improved and can reach 65% or higher of the traditional 50% degassing rate.

Online Degasser is easy to maintain

Only the rotor and the turntable need to be placed at the bottom of the degassing box lining, and the remaining parts do not need to be replaced, the modification cost is low, and it is convenient to upgrade the degassing equipment.

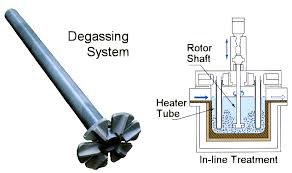

Online Degasser includes a box body, a box cover that covers the box body, and a rotor.

The rotor extends into the box through the bottom of the box.

The upper end of the rotor is coaxially connected with the turntable, and the interior of the rotor and the turntable are hollow and communicated.

Among them, the shape of the turntable varies from a traditional disc structure to a streamlined round head structure.

The streamlined round head structure consists of two parts: the cylindrical shape and the truncated cone shape.

The air outlet is ring-shaped on the side of the cylindrical part, and two groups are arranged in the box.

The rotor and the turntable can change the traditional nearly straight upward airflow into multiple spiral upward airflows, so that the fine bubbles are more evenly dispersed in the molten aluminum, thereby improving the degassing effect.

Experimental verification shows that the bubbles generated by the turntable are small and evenly distributed, achieving the most effective degassing and slag removal effect.

The material of the turntable is silicon nitride or graphite. The speed of the rotating turntable can be changed by a variable frequency motor, and the speed can be adjusted in the range of 0-900rpm to meet the needs of the process.