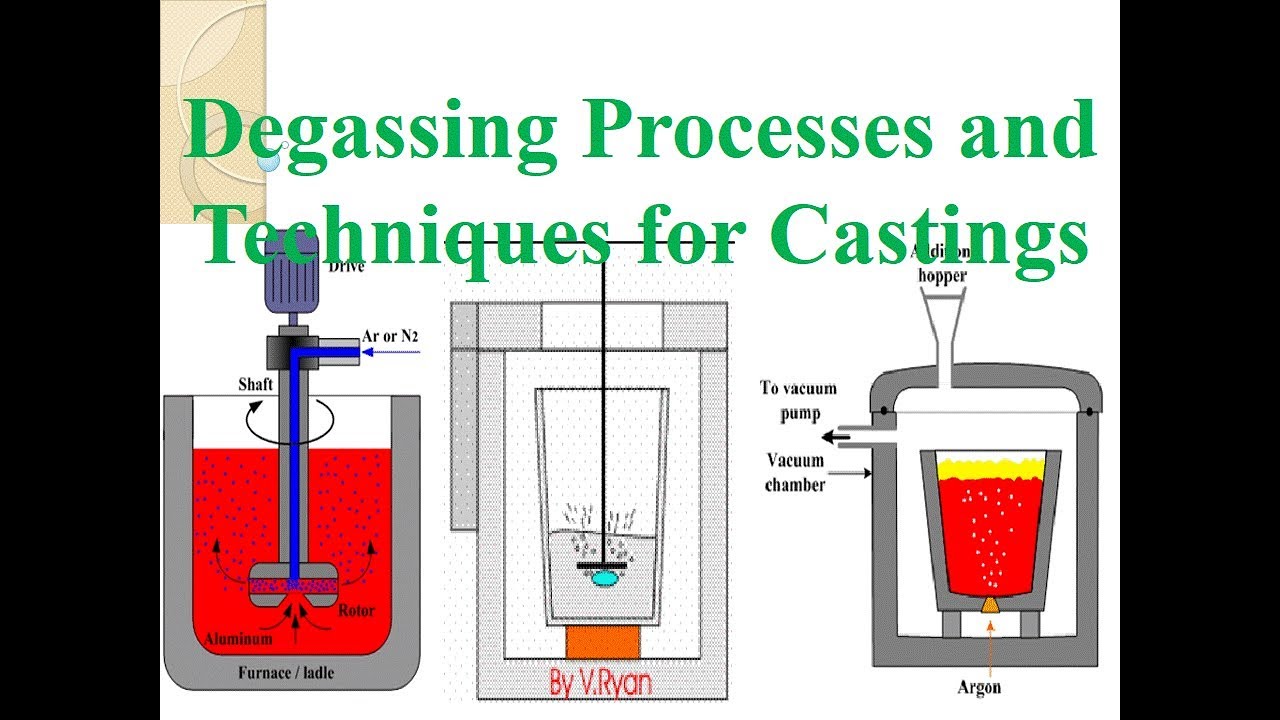

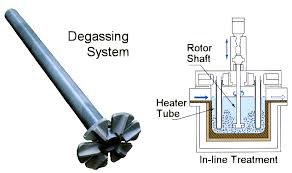

Nitrogen Degassing Unit is used to reduce the oxide and hydrogen in the aluminum liquid, reduce the loss of aluminum and refining agent in the slag removal process, and also reduce the oxide deposition on the furnace wall.

Through automatic cycle refining timing and setting, automatic degassing and refining agent injection can be used respectively.

During the smelting process of aluminum alloy, molten aluminum, air and water vapor react to produce hydrogen and dissolve into the molten aluminum. When the molten aluminum solidifies, the hydrogen will be separated from the molten aluminum.

The hydrogen content and non-metallic inclusions of molten aluminum alloy in the melting and casting workshop will seriously affect the quality of the casting.

Usually during the condensation process, as the solubility of hydrogen decreases, hydrogen has no time to escape from the solution, and non-metallic inclusions have no time to float to the surface before entering the crystallizer.

In the subsequent rolling process, the white spots and pinholes on the surface of the sheet and foil will increase, the mechanical properties of the material will decrease, and the product will eventually be scrapped.

Therefore, the Nitrogen Degassing Unit must be used to degas and purify the aluminum alloy melt.

As we all know, because the aluminum alloy wire has the performance that ordinary steel core aluminum stranded wire can’t match.

At present, aluminum alloy wire has been widely used in the world, and its consumption has reached 20% of the total amount of wire.

The concentration of aluminum alloy wires is that the wires are locally brittle and have poor bending performance. The main reason is that the magnesium element in the aluminum alloy liquid changes the dissolution rate of hydrogen in the liquid aluminum, improves the solubility of hydrogen, and makes the aluminum alloy liquid contain The amount of hydrogen is much higher than ordinary molten aluminum.

If the hydrogen and impurities in the aluminum alloy liquid are not removed, the mechanical properties such as bending and torsion of the aluminum alloy wire will hardly meet the quality requirements.

At present, large domestic aluminum processing industries and manufacturers of aluminum-magnesium-silicon alloy wires have installed degassing equipment on aluminum casting and rolling production lines to reduce the hydrogen content of aluminum alloy liquid to less than 0.12mg/100ml.

The performance of alloy wires has met the needs of engineering, and alloy wires can be widely used.

In view of this, it is particularly important to develop efficient and stable degassing devices. A new type of degassing device is introduced below.