Molten Metal Foam Filter

Smelting aluminum alloys presents a number of difficulties. The low density of aluminum alloys contributes to the formation of gas shells and porosity, since gases easily penetrate into the metal medium and saturate it. Aluminum is easily oxidized. It is difficult to clear the melt of slag and oxides.

Slag and oxides remain in the melt in finely divided form in a suspended state, which significantly affects the quality of the alloy.

The use of fluxes (zinc chloride, cryolite) or modifiers also does not allow the melt to be cleaned completely, since it is difficult to separate them from the melt.

In the preparation of aluminum alloys, the purity of the starting materials and the accuracy of the composition of the charge are especially important.

Often, insignificant amounts of harmful impurities significantly impair the mechanical properties of the alloys.

All this necessitates a particularly careful sorting of waste. Without remelting, they can only be used if their chemical composition is known.

Scrap of unknown origin or poorly sorted and remelts (secondary alloys) containing many oxides and harmful impurities should be melted down into pigs.

During remelting, the melt is cleaned of impurities and chemical analysis is performed.

Melting and casting of aluminum is carried out with strict observance of the temperature regime and constant and accurate control of alloy heating.

Even slight overheating and excessive aging of the alloy at high temperature lead to its excessive saturation with gases and oxides and the appearance of shrinkage shells.

To remove oxides and slags, it is necessary to use fluxes that act both chemically and mechanically.

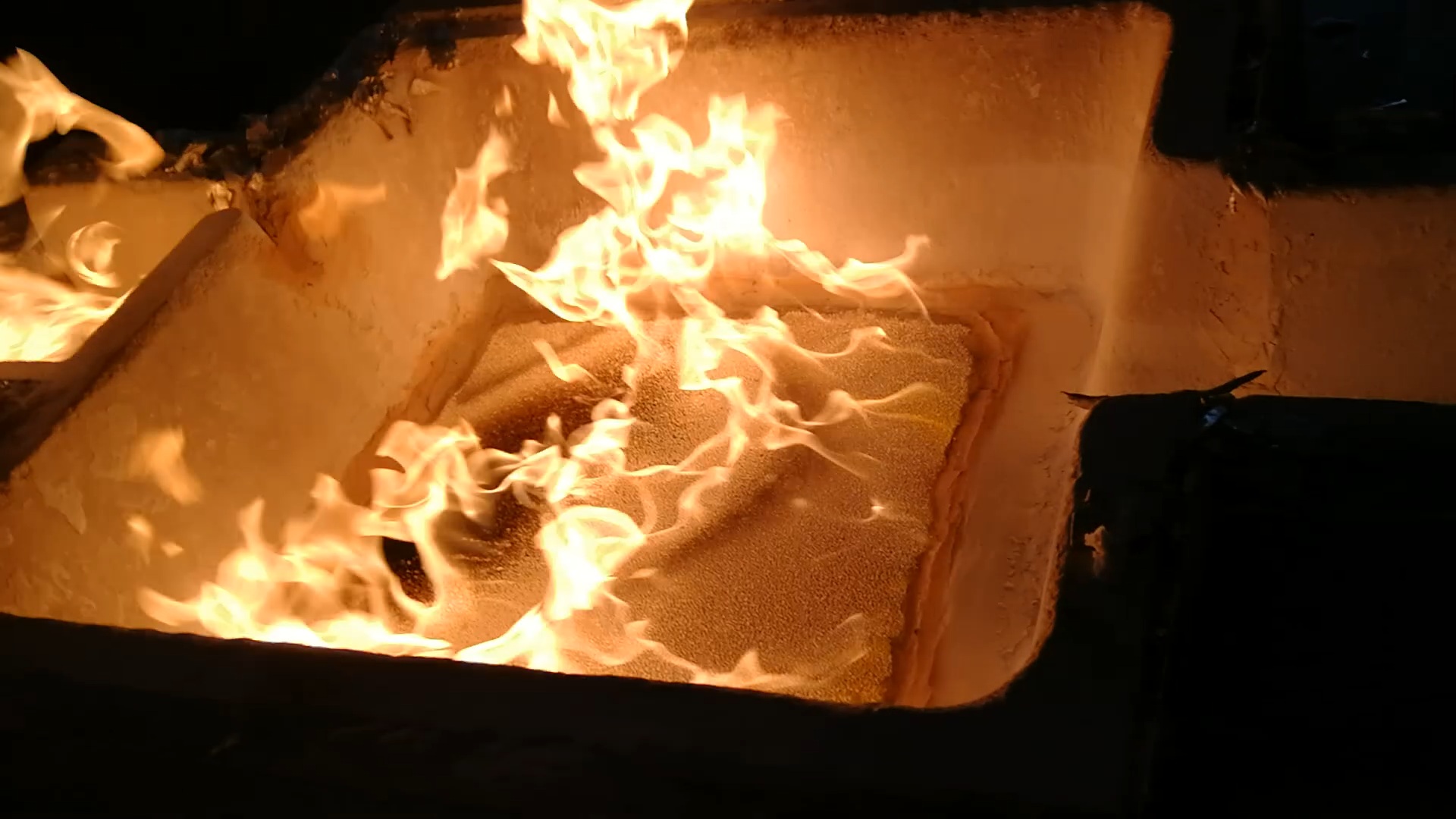

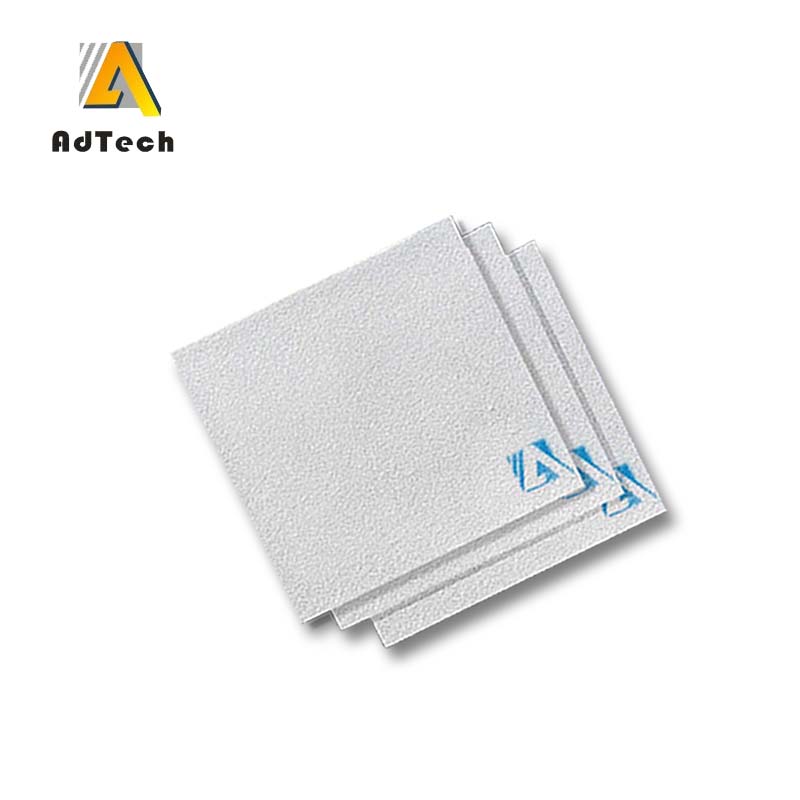

Molten Metal Foam Filter

[…] more pure, and greatly reduce the occurrence of waste problems such as blistering and holes. The molten metal foam filter has excellent thermal shock resistance, chemical resistance and high temperature […]