Molten Metal Cleanliness When Casting Aluminium

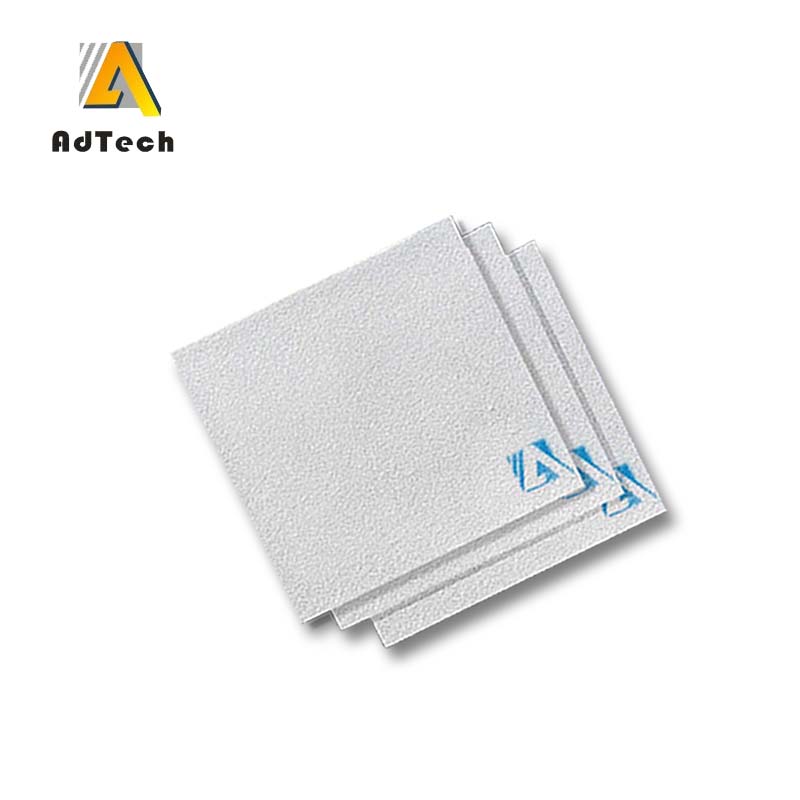

Our ceramic foam filter use good foam and high purity ceramic as raw material, can removes non-metal solid mixture from aluminium and aluminium alloy fusant effectively in your aluminium casting industry.

Advantages:

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

Function:

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

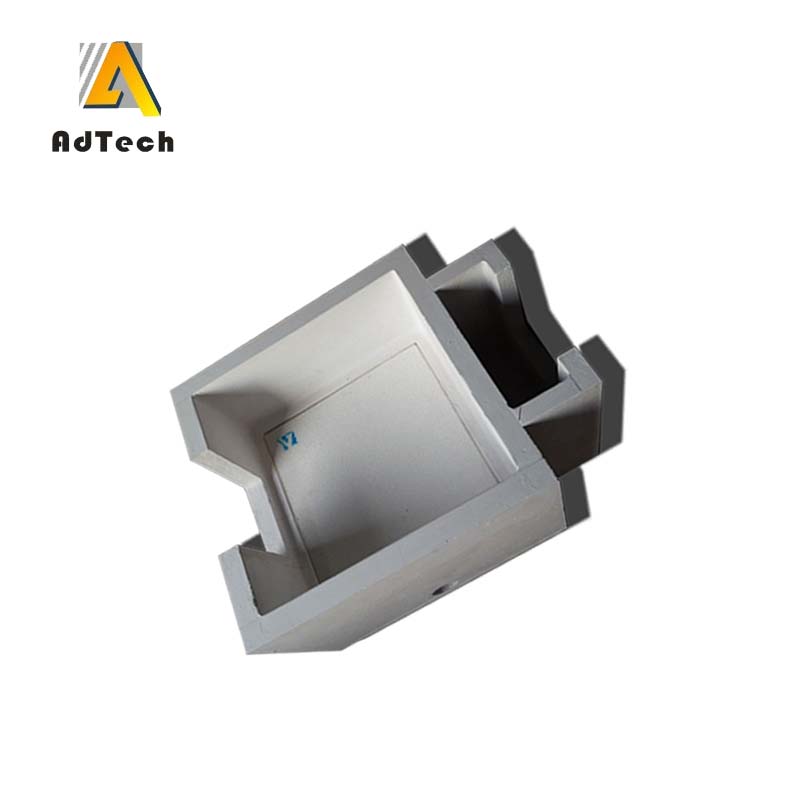

AdTech Ceramic Foam Filter for Aluminum Casting

It is alumina based ceramic foam filter which are used for temperatures up to a limit of 1100℃. CFF-A is most suited for the filtration of aluminum and its alloys.

Features:

1. High strength

2. Outstanding thermal shock resistance

3. Available in various of shapes, sizes and pore sizes

4. Adaptable to all vertical and horizontal gating systems, e.g. aluminum alloy rod continuous casting-rolling line

Functions:

1. Effective inclusion removal

2. Fewer casting defects

3. Increasing casting yield

4. Less scrap

AdTech skilled and dedicated people are the key to creating good quality castings. Because each and every casting is unique, consistent quality is the product of understanding the customer’s casting requirements, knowing the variety of process variables, defining and documenting the parameters, and developing and continually executing production procedures.