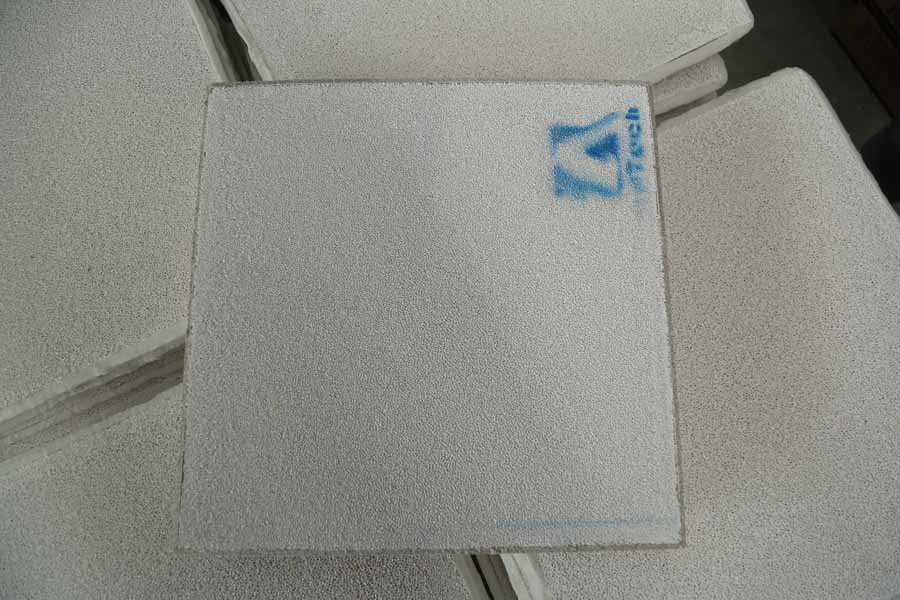

Molten Filtration is used to filter and purify molten aluminum, with light weight, durability, and excellent heat resistance.

In the manufacturing process of aluminum foil, related castings and aluminum plates, the Alumina ceramic foam filter we provide is widely used.

Foam Filter Manufacturers provide high-quality Foam Ceramic Filter, and we have won a huge customer base in the market. Our quality analyzer will inspect these Foam Ceramic Filters in strict accordance with various quality standards to provide our customers with a perfect product range.

The content of aluminum in the crust is second only to oxygen and silicon, ranking third, and is the most abundant metal element in the crust. The development of the three important industries of aviation, construction, and automobiles requires the characteristics of materials to have the unique properties of aluminum and its alloys, which greatly facilitates the production and application of this new metal aluminum.

The use of aluminum alloy castings is increasing, and the requirements for castings are getting higher and higher.

In addition to the requirements to ensure chemical composition, mechanical properties and dimensional accuracy, aluminum alloy castings are not allowed to have shrinkage, shrinkage, porosity, slag holes and other casting defects.

The purification of molten aluminum is one of the measures to ensure high-quality aluminum alloy products, and it is also the main means to improve the overall quality of aluminum alloys.

The refining effect of molten aluminum has an important influence on the formation of pores, shrinkage cavities and inclusions, and directly affects the physical and mechanical properties of aluminum alloy castings.

Without high-quality molten aluminum, even if the subsequent processing is advanced, the defects will always exist in the product once they occur, and high-quality castings are difficult to obtain. Therefore, we must pay attention to the gas and inclusions in the molten aluminum, and take measures to remove the gas and inclusions in the molten aluminum.

Adtech China-www.adtechamm.com-sales@adtechamm.com

The imminent advantages of Molten Aluminum Filter bring the best results in the foundry industry

The passage of metal in molten form may be an important step in the formation of the final casting. This is solved by installing Molten Aluminum Filter. Since there are no impurities and unnecessary bubbles are formed, the correct design can be provided. The machinery industry is doing its best to obtain the highest quality castings, and this type of Foundry Filter may have the greatest advantage.

If you need high porosity and mechanochemical activity in your work, you need to choose a brand that can provide the same brand as you. Filtec foam ceramic foam filters are ideal when phosphate-free and high thermal corrosion resistance are required.

Alumina ceramic foam filter can remove inclusions, reduce trapped gas, provide laminar flow when filtering molten aluminum, and increase dimensional tolerances during production. Zirconia filters have many uses, including their use in molten steel and alloy filtration.

The melting point of aluminum is 660°C, which means that it can be transformed (melted) from a solid state to a liquid state at this temperature.