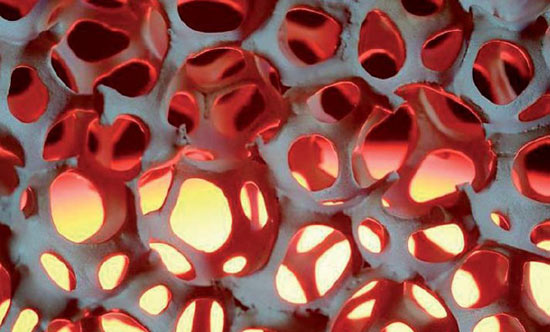

Molten Aluminum Filter Kolhapur aluminum can effectively remove the large inclusions in the aluminum liquid and absorb the micron-level fine inclusion particles, which can improve the surface quality, improve the product performance, improve the microstructure, and increase the yield. Widely used in the production of aluminum profiles, aluminum foils, and aluminum alloys

Ceramic foam filter Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

Ceramic foam filter Pore Size (PPI): 10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filters in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

Kolhapur aluminum’s engineer introduced the relevant only

The number in front of the English letter PPI represents the hole density of the product, corresponding to the uniformity of the hole.

For example, the model 10PPI indicates that the foam ceramic filter product has a pore uniformity of 7 to 13 holes at any 25.4mm length.

Aluminum and aluminum alloy production processes often use 178x178x50mm, 230x230x50mm, 305x305x 50mm, 381x381x50mm, 432x432x50mm, 508x508x50mm, 584x584x5, a total of seven specifications of ceramic foam filter products. Other specifications and models are required. Both parties can negotiate.

The size and size deviation of the Molten Aluminum Filter Kolhapur aluminum used in the foundry

For the size and shape deviation of the ceramic foam filter plate, we mainly consider the side length tolerance, which has a great influence on the use of the ceramic foam filters plate. Diagonal length tolerance, plane spacing thickness tolerance, inclination angle deviation is 5 indicators. The following filter plate dimensions are allowed to vary 381mm 381mm~430mm 430mm side length tolerance, mm ±3 ±4 ±5 diagonal length tolerance, mm ±5 ±7 ±9 plane clearance, mm 3 6 thickness tolerance, mm allowable deviation ±2 sides Angle ±1° Note 1: Diagonal deviation refers to the difference between the length of two diagonal lines on the larger surface of the filter plate;

Note 2: The plane gap is to place the larger part of the filter plate on the platform, and measure the gap between the filter plate and the platform;

Note 3: The side bevel angle refers to the angle between the side bevel surface and the larger surface.

Note 4: The filter plates are all products with a theoretical thickness of 50mm and a side angle of 17.5°. The transmission foam ceramic filter plate refers to the effective filtering area of the product. The higher the light transmittance, the fewer blind holes, the more effective the filter holes (pits), and the better the filtering effect.