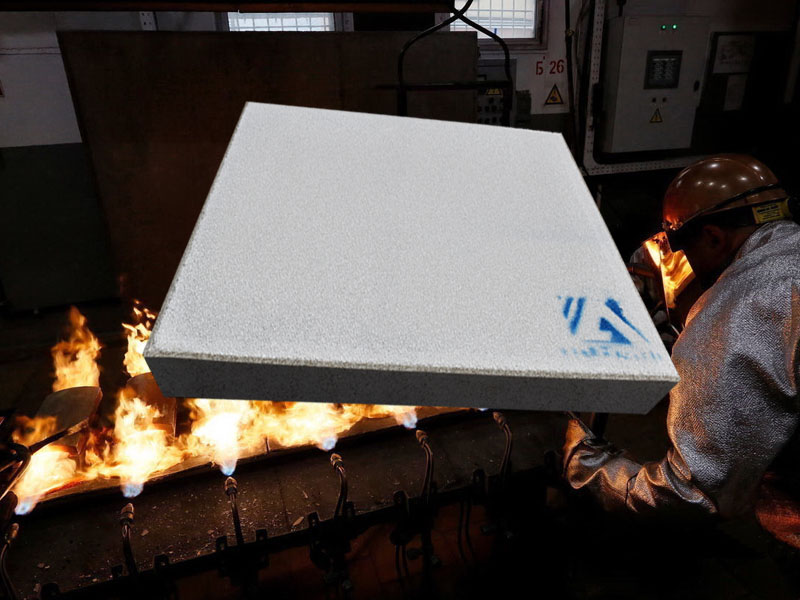

Molten Aluminum ceramic foam Filter Kai Aluminium Bd is a filter medium made of high-temperature resistant materials, which chemically reacts with molten aluminum at high temperatures to rust.

The filter media must also maintain structural integrity, for example at elevated temperatures, and of course, must capture or prevent solids in chemical reactions and/or mechanically prevent fluids and semi-liquids from flowing through them.

In the melting, refining, and manufacturing of metals, especially in molten metal casting, it is desirable to separate inclusions from molten metal.

The inclusion of such impurities leads to the appearance of raw materials used for smelting, from slag, scum, and oxides, in the form of slag, aggregates, and oxides on the surface of the melt, and in the form of small fragments of refractory materials. Used to make chambers or containers that melt metal by melting.

If these inclusions are not removed from the molten state of the metal, it may cause the final solid metal body (the final product of the casting operation) and/or the weakening of the porosity reduction point.

Generally, the granular refining agent is added to the aluminum liquid first, and the slag removal treatment is performed after the reaction is complete.

The aluminum liquid filtering device is a degassing box used to remove hydrogen in the aluminum liquid.

Finally, the impurities in the aluminum melt are filtered, after passing through the filtering device.

Especially in the case of using Molten Aluminum Filter Kai Aluminium Bd, after long-term use, the pores will be blocked by sodium chloride adsorbed on the surface.

Therefore, Molten Aluminum ceramic foam filters have a multilayer network structure. The pore size decreases along the flow direction of the liquid aluminum. By setting the particle size of the granular material, the granular material can be continuous or stratified in the flow direction of the aluminum melt, and the same effect can be achieved, that is, longer filter life can be obtained.