Molten Aluminum Filter Dhaka Aluminium can effectively remove large inclusions in molten aluminum and adsorb micron-sized particles of fine inclusions.

It plays a role in improving surface quality, product performance, microstructure and yield. Aluminum melt filter is widely used in the production fields of aluminum profile, aluminum foil, aluminum alloy and so on.

Inclusions and gases in the metal have a significant impact on strength, fatigue resistance, corrosion resistance, and stress corrosion cracking performance.

Effective control of oxidized inclusions in the melt can improve the quality of cast rods and rolled plates, and has become a common goal pursued by the metallurgical, casting and material industries of all countries.

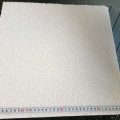

At present, filtration and purification methods are widely used to remove inclusions in aluminum alloy melts. Practice has proved that the ceramic foam filter plate is the most effective tool for removing oxidized inclusions in molten aluminum.

AdTech ceramic foam filter plate is installed in the CFF filter box.

The molten aluminum flows through the filter box from the furnace mouth, and then enters the distribution plate through the flow trough.

With the extension of the filtration time, the inclusions on the surface of the filter plate and the pore wall increase, and the filtration flow rate decreases.

The choice of CFF should be based on the flow of molten aluminum.

The cleanliness of the melt, the maximum content of inclusions and the total flow of the melt filter plate must be considered. It is mainly determined by the size and porosity of the filter plate. The greater the porosity of the filter plate, the worse the slag removal effect. For aluminum castings with very strict requirements, a filter plate with a smaller pore size should be selected.

Molten Aluminum Filter Dhaka Aluminium can filter aluminum and aluminum alloy smelting non-metallic solid inclusions economically and effectively.

The ceramic foam filter plate has the advantages of uniform pore size, high through-hole rate, sufficient sintering, good bending and compressive strength, and good filtering effect.

Foam ceramic filters are widely used in continuous casting, semi-continuous casting, gravity casting, low pressure casting and other aluminum and aluminum alloy melt filtration and purification equipment.

Vedanta expects India’s aluminum production to reach 5 million tons in 5-6 years

A senior at Vedanta Ltd said on Thursday that India’s aluminum production is expected to reach 5 million tons per year in five to six years, an increase of about a quarter from current levels.

Fitch Solutions said that in the next few years, India will become the “leading player” in the growth of aluminum consumption, because the country hopes to solve the infrastructure shortage, so there will be more construction projects.

Fitch Solutions expects that India’s aluminum consumption will increase from the current 2.6 million tons/year to 9.5 million tons/year by 2030.

It is expected that production growth can be achieved in the next 12-18 months, which will help reduce Vedanta’s dependence on imported alumina.

The current annual aluminum output in India is 4 million tons, and it is expected to reach 5 million tons in the next five to six years.