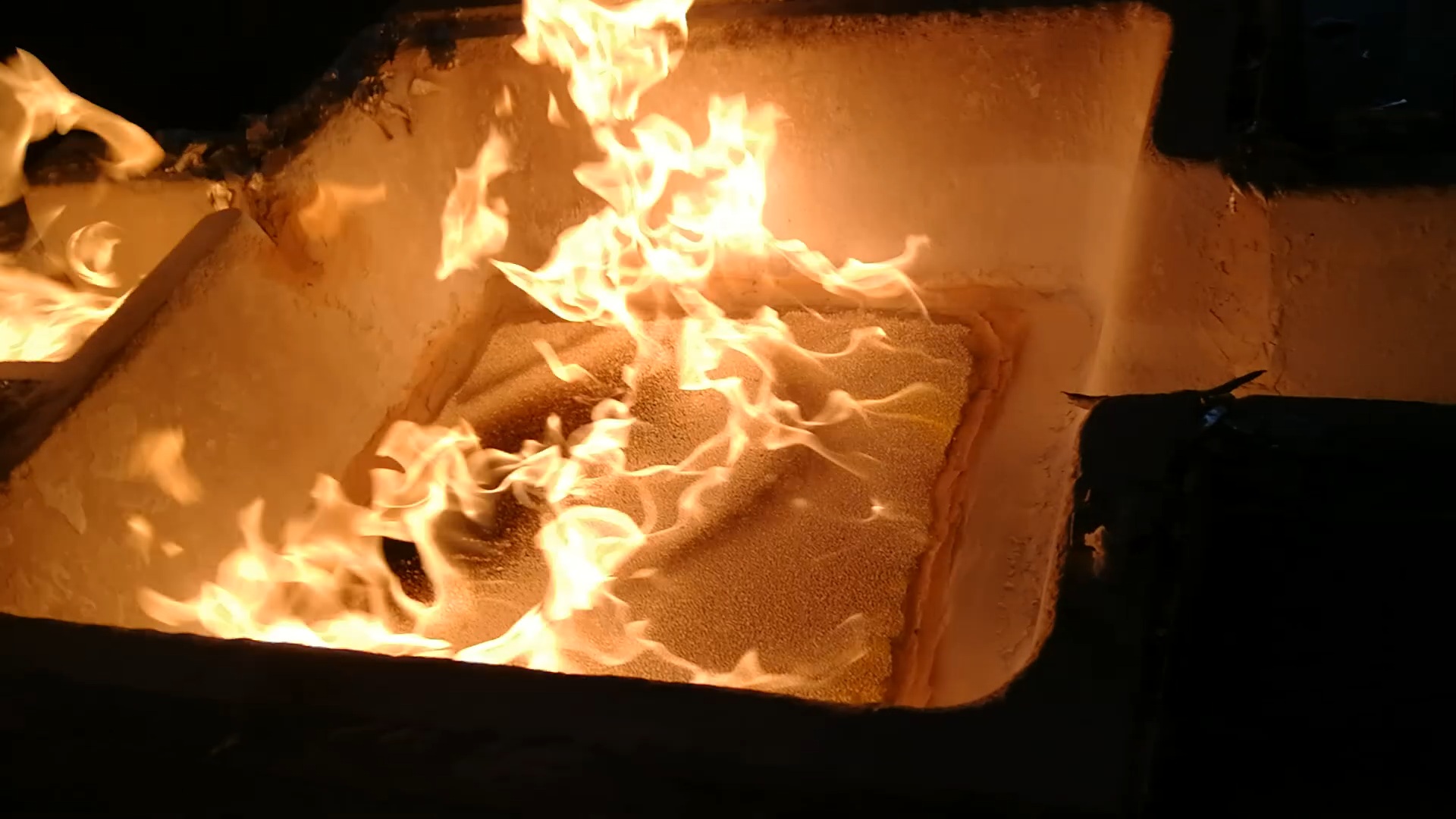

Molten Aluminum Filter Coimbatore filters out molten aluminum inclusions larger than the pore size of the filter surface through mechanical separation, and precipitates at the flow end of the liquid metal of the filter.

As the number of inclusions on the filter surface increases, a layer of “filter cake” will gradually form, further reducing the flow path of the molten metal. Therefore, the surface of the new filter media can better filter out inclusions.

In addition, the inside of the media also has a filtering effect. Among the many small holes that enter the ceramic body, some show small holes, and some have dead ends. These different areas of change are the potential locations involved in the interception. There is also a “filter cake” effect inside the filter.

Molten Aluminum Filter Coimbatore is composed of multiple bridge-shaped opening micropores with uniform pore size distribution and interconnection. When the fluid passes through these micropores, the suspended solids, colloidal particles, and macromolecular organic matter in the fluid are trapped or adsorbed in the micropores in the road, so as to achieve the effect of uniform purification and filtration.

The ceramic filter plate produced by our company has high strength, wear resistance, high temperature resistance, corrosion resistance, no pollution, uniform pore size distribution, long service life and simple regeneration. It is used for aluminum liquid filtration and solid-liquid separation. complete.

Advantages of Molten Aluminum Filter

Using the principle of filtration and adsorption, most of the substances in the aluminum liquid can be effectively removed, and solid impurities can be effectively adsorbed.

Damaged slag will not fall off, effectively reducing the pollution of molten aluminum.

Good thermal shock, improve the corrosion resistance of molten metal.

Automatic flow creation, calibration steps, and precise dimensions make the filter fit the device firmly.

Improve surface appearance and performance, and purify molten aluminum.

The company’s ceramic foam filter uses fine foam and high-purity ceramics as raw materials, which can effectively remove the non-metallic solid mixture in the aluminum liquid and aluminum alloy flux in the aluminum casting industry.

Foam ceramic filters are widely used in continuous casting, semi-continuous casting, gravity casting, low pressure casting aluminum casting filter devices.

Hindalco Industries Ltd., the flagship company of the Aditya Birla Group of metals, is a leader in the aluminum and copper industries. The turnover of the metal giant is combined with Rs. At 600.128 million yuan (approximately US$15 billion), Hindalco Industries is the world’s largest aluminum rolling company and one of Asia’s largest aluminum producers. Its copper smelter is the world’s largest single-site custom smelter.

Established in 1958, Hindalco Industries commissioned its eastern aluminum factory in Renukoot in 1962. Later acquisitions and mergers in Australia, Indal, Bila Copper and Cutie and Mt.Gordon copper mines strengthened the company’s position with value-added alumina, aluminum and copper, and the products were vertically integrated by acquiring captive copper concentrates.

In 2007, Novelis’s world-leading aluminum rolling and acquisition can be recycled, marking an important milestone in the history of India’s aluminum industry. According to its collaboration with Novelis Times Hindalco Industries ranks among the world’s top five professional aluminum alumina as an integrated producer with a combination of low-cost and high-end aluminum rolling facilities and functions, and a global footprint in 12 countries outside of India. Its consolidated turnover is US$15 billion and its location is among the Fortune 500 companies in the world.