Molten Aluminum Filter Aluminium Bangladesh is very important to the quality of aluminum melt, which greatly affects the post-processing performance and quality of the final product. Therefore, all countries in the world like the purification of aluminum melt very much.

Features of Molten Aluminum Filter Aluminium Bangladesh

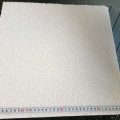

1. Ceramic foam filter can effectively remove large liquid aluminum inclusions.

2. The ceramic filter plate can remove small inclusions of a few microns in size that are reactive in the conventional process of molten aluminum. At the same time, the small splint material is filtered, because the number of effective liquid aluminum nuclei is reduced, the liquid aluminum is swelled and nucleated under freezing conditions, the solidification time is shortened, and the structure is refined.

3. Reduce the hydrogen content in molten aluminum. Hydrogen can be adsorbed on some oxide inclusions, and the mixed oxide core can grow into bubbles and inclusions, so its removal gas can also be filtered.

The selection of the ceramic foam filter is first determined according to the quality requirements of the final casting product based on the impurity content in the aluminum melt and the melt transfer flow rate.

The impurity content is high and the casting quality is normal. A large mesh ceramic foam filter can be used, and a glass fiber cloth coarse filter is added in front of the foam ceramic filter. At this time, it is very important to use glass fiber cloth for coarse filtration in semi-continuous casting.

There are many reasons for aluminum pollution

On the one hand, during the melting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state, which is easily oxidized, reacts with water vapor, and easily absorbs hydrogen. It is also easy to produce metal slag (such as furnace lining debris, chlorides, carbides in the stream, etc.) and coarse intermetallic compound particles.

On the other hand, part of the scrap in the combined charge contains some non-aluminum impurities during the recycling process. Because the waste comes from process waste, geometric waste and off-site waste from various processes in the factory.

These impurities make the slab produce bubbles and inclusions, which seriously affect the purity of the metal melt, and affect the processing performance, mechanical properties, corrosion resistance and appearance quality of the product.

India has one of the most dynamic aluminum markets in the world, with aluminum production and consumption increasing every year.

Large-scale infrastructure projects are expected to bring more aluminum consumption growth. India’s power, construction, packaging and transportation industries provide important growth opportunities for aluminum consumption. These industries are expected to double in the next 10 years. Multiple growth.

In India, per capita aluminum consumption is 1.3kg. Compared with China’s per capita aluminum consumption of 12kg and Europe’s per capita aluminum consumption of 25kg, India has a lot of room to increase.

For the first time, the Indian Aluminum Industry Exhibition and the Aluminum Association of India jointly cooperated with the Indian Aluminum Industry Association. Exhibitors highly recognized the professional visitors invited by the exhibition and the authority of the Aluminum Association of India. After soliciting the opinions of most exhibitors, the International Aluminum Industry Exhibition of India in 2021 will continue to be held in the region. Aluminum Association of India The aluminum industry conference will continue to be held. The theme of the conference in 2021 will focus on the raw material technology of the aluminum processing application industry in India and the application of aluminum materials in the automotive manufacturing industry.

In 2021, the Aluminum Industry Conference of the Aluminum Association of India will gather strength for the second time to help hold the International Aluminum Industry Exhibition in India.