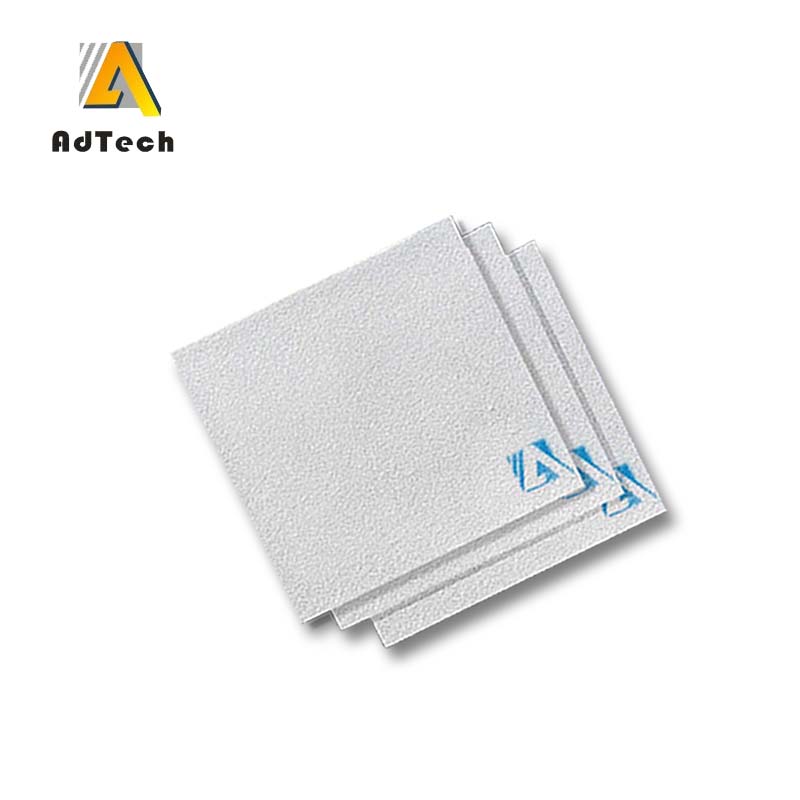

Molten Aluminum Filter

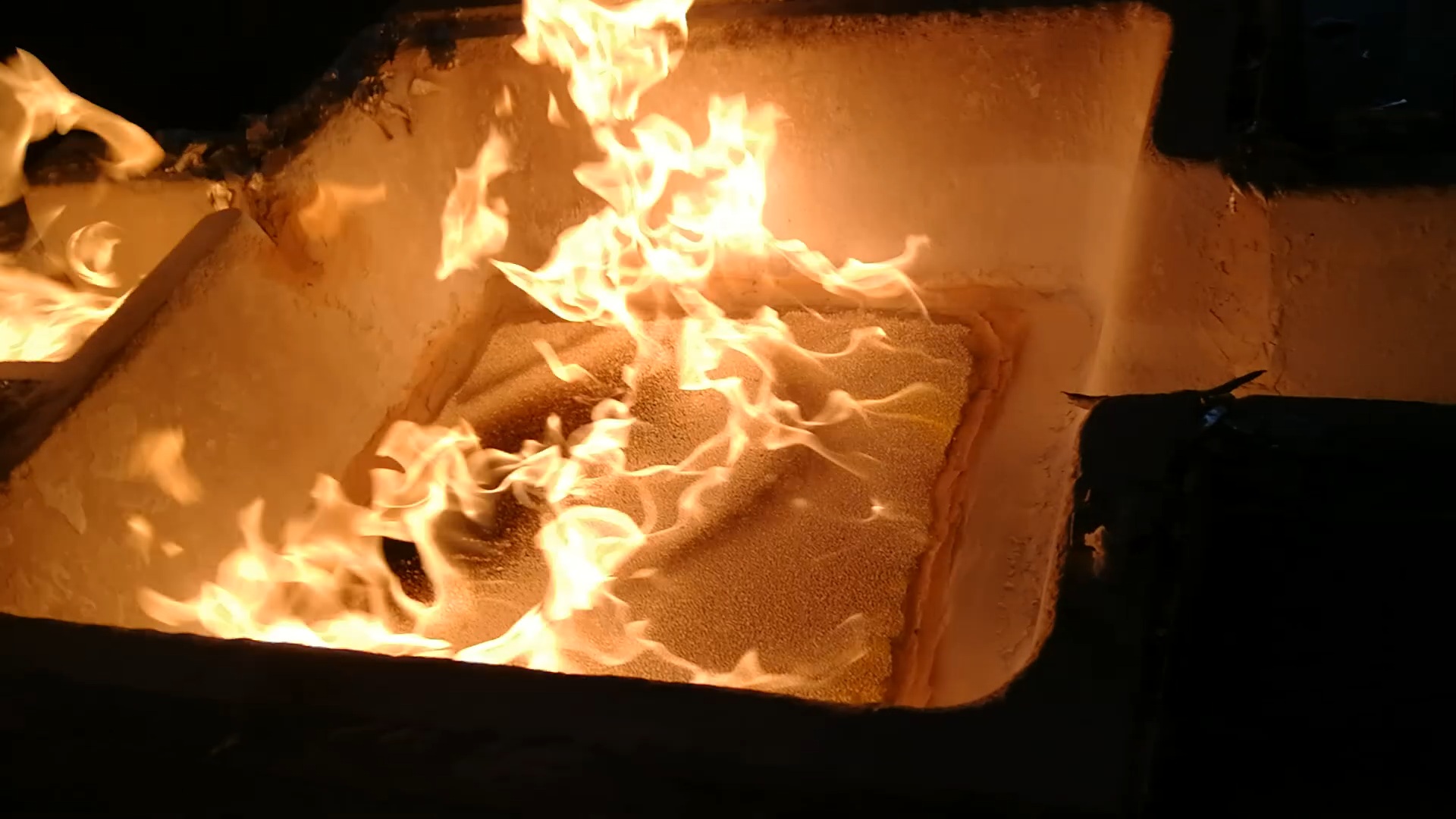

Molten Aluminum Filter is a common practice in industry.

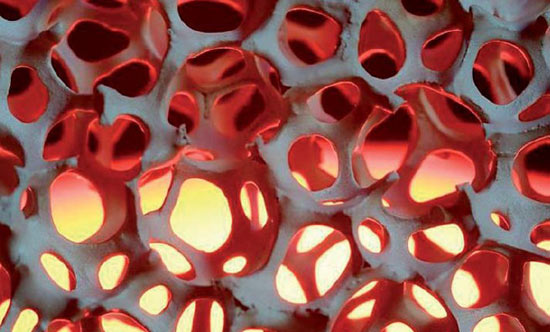

In particular, filtration of molten aluminum using reticulated foam filters is widely practiced in the art.

It is well known that the refractory and chemical stability of the filter material is of critical importance in obtaining effective inclusion particle retention and to avoid release of reaction products from the filter material into the molten metal as a contaminant.

Molten Aluminum Filter use silica as a refractory foam material, as it tends to be inexpensive, easily processed.

Silica also has a low thermal expansion and compressive modulus. Unfortunately, it is known to be highly reactive in molten aluminum alloys, especially in magnesium containing alloys.

The Merits of Molten Aluminum Filter include

Reduce gas and inclusions that are contained in the casting, reduce the turbulence level of molten metal when filling the mold, reduce surface defects in castings, and significantly reduce the rejection rate of casting

Increase the compressive sealing of casting, increase elongation and tensile strength of casting, improved surface finish of casting, improve the mobility of molten metal, increase the filling capacity and the feeding capacity of melt.

Simplify the casting system, reduce the length of the lateral flow channel, improve casting yield.

Reduce the processing time and tool abrasion, improve surface quality of casting.

Ceramic foam possesses high mechanical strength, chemical stability, high resistance to thermal shock and liquid metal flow shock even under high temperature environment. No slag or broken in working process, to ensure the quality and stable chemical composition of the molten metal.

Has a large and stable metal flow, even if the high content of inclusions in molten metals, ceramic foam filter will not be plugged.ery high dimensional accuracy, can be automatically placed in production line.