Metallurgical Molten Aluminium Foundry Ceramic Filters

Aluminium Foundry Ceramic Filters For Liquid Aluminum is the most widely used filter in the area of aluminum melt filtration . The advantage is a high porosity, high filtration efficiency, easy to replace, low cost, adaptability, can also be isolated by filtration of solid inclusions portion of the liquid inclusions ; the disadvantage is the high temperature strength is low, short-lived (mostly single use) filtering small amount.

Aluminium Foundry Ceramic Filters is able to remove oxides from the surface of aluminum and thus increase casting quality. More and more aluminum sheets and foil manufacturers are today using these filters.

Adtech is one of the biggest foundries as supplier of ceramic foam filters products in India as well as global industrial market. The company supplies these high quality filters to its clients involved with the production of aluminum sheets and foils.

Aluminium Foundry Ceramic Filters Instructions for use

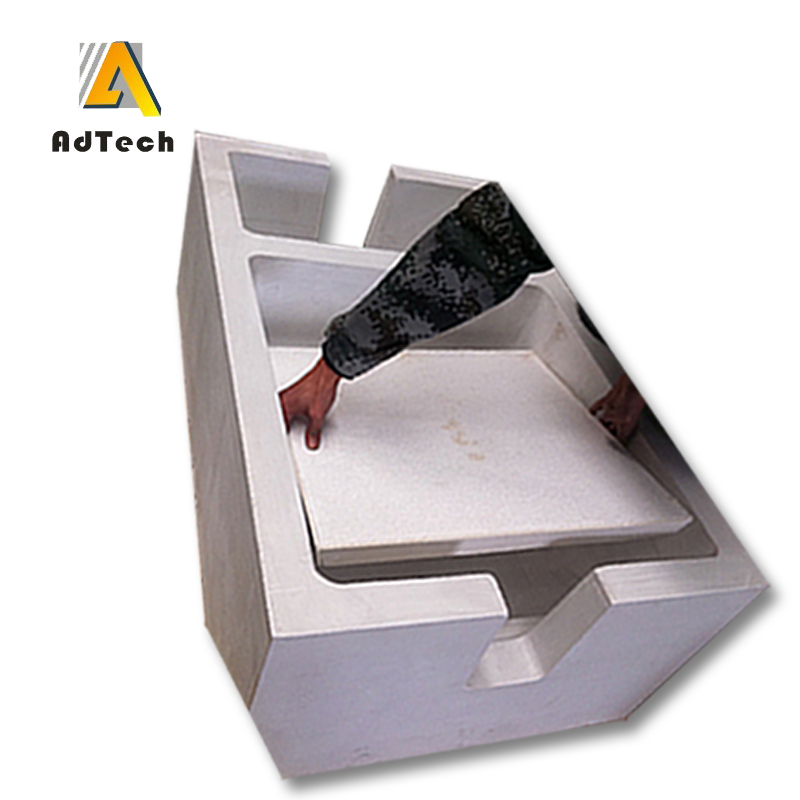

1. Check and clean the filter box surface debris to keep the filter box clean and free from damage.

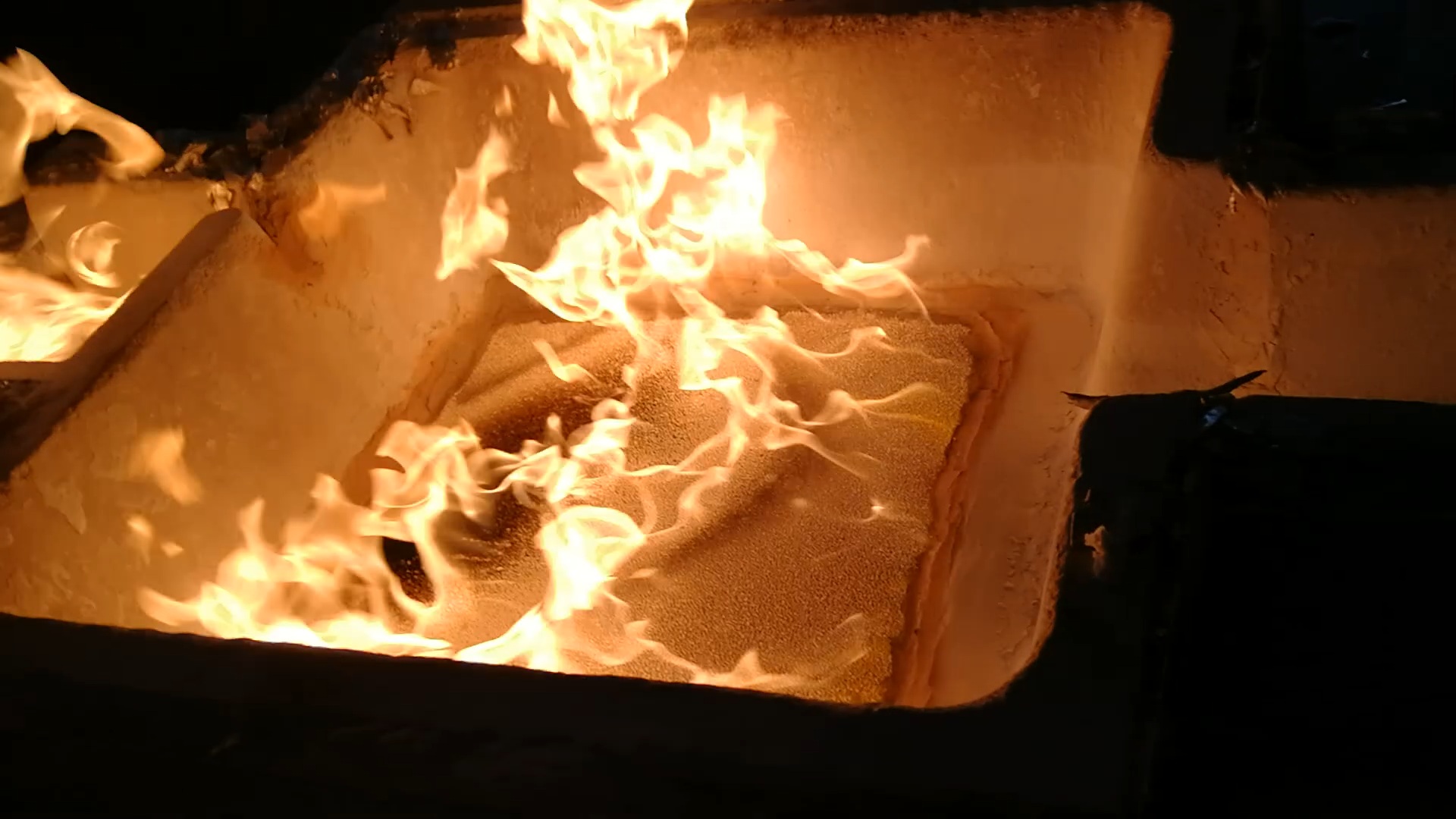

2. Gently place the filter plate in the filter box and press the seal gasket around the filter plate with your hand to prevent the aluminum liquid from flowing or floating. Preheat the filter box and the filter plate evenly so that it is close to the temperature of the aluminum liquid. The preheating temperature of the filter plate is not lower than 260°C. Preheating to remove adsorbed water helps to facilitate the opening of the initial filter pore size at the moment and prevents the heat from rising and shrinking to block some holes in the filter plate. Preheating can be electric or gas heating, normal heating 15-30 minutes.

4. Pay attention to observe the change of the aluminum hydraulic head when casting, and maintain the flow of normal demand aluminum liquid. The normal initial pressure head is 100-150mm. When the liquid begins to pass, the pressure head will drop below 75-100mm, and then the pressure head will slowly increase.

5. During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the flow tank should be filled with aluminum water to avoid the perturbation of the aluminum liquid too large or too small.

6. After the filtration is completed, remove the filter plate in time and clean the filter box.

Aluminium Foundry Ceramic Filters Features

Effectively remove the inclusions and reduce the scrap rate.

Improve surface quality and product performance.

Improve microstructure.

Aluminium Foundry Ceramic Filters selection and using

In general, choose alumina ceramic foam filter should take into account the requirements of finished product quality, the flow capacity of the molten aluminum tank, the amount of the total filtration of molten aluminum and aluminum liquid cleanliness and other factors.

1. Clean the filter box.

2. Gently put the filter into the filter box, and press the gasket around the filter to prevent the molten aluminum to flow from the side.

3. Even preheat filter box and filter plates, closer to the temperature of molten aluminum casting.

4. Observe aluminum liquid hydraulic head change, the normal initial pressure head is 75-150 mm. When the Alumina liquid began to pass, the pressure head will be reduced to 25 mm below, then the pressure head will gradually increase.

5. After filtration, timely remove the filter plate, clean the filter box.

Aluminium Foundry Ceramic Filters Advantages

1. Using the principle of adsorption, it can effectively remove large inclusions in the aluminum liquid and effectively adsorb fine inclusions of small size;

2. Do not drop slag, effectively reduce the pollution of aluminum liquid;

3. Good thermal shock resistance and improved resistance to molten metal corrosion;

4. Automated assembly line production, three calibration procedures, accurate dimensions, and more in line with the filter box;

5. Improve surface quality, improve product performance, and improve microstructure.