On July 12, 2019, a group of three technicians, purchasing directors, and project managers from a Korean company visited AdTech.

The company has production lines such as ingot, hot rolling and cold rolling, of which the ingot production capacity is about 800,000 tons per year, which is the largest aluminum company in Korea.

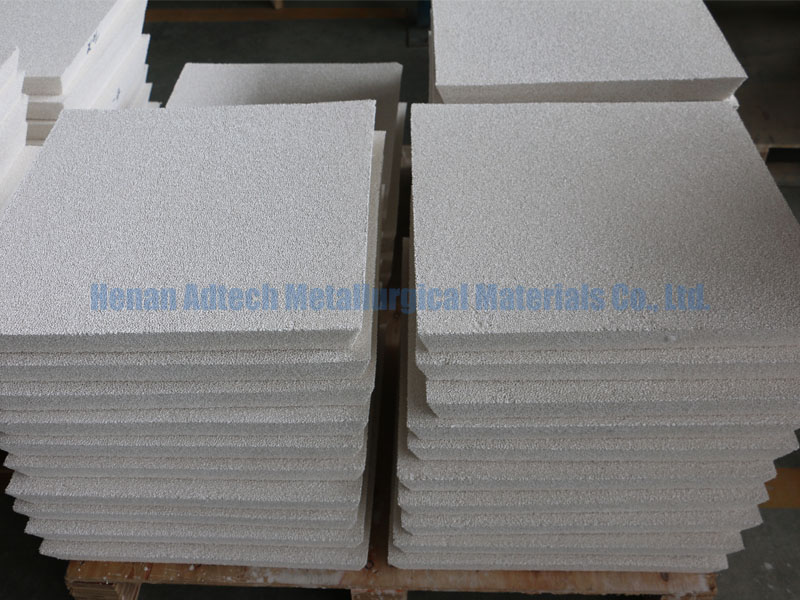

The Korean customer visited the production line of filter plates, the production line of fiber products and the production line of hot top parts. A line of detailed research on the production process, raw material control, operation standards and production equipment of AdTech products fully affirmed AdTech’ workshop environment, quality control and inspection measures. Highly appreciated the implementation of the ISO quality system in the workshop.

Subsequently, a group of three people, under the leadership of the factory personnel, visited the high-precision equipment workshop with great interest, and detailed technical parameters, physical and chemical indicators, and use cases of the overall online degassing equipment, online filtration equipment, and overall flow tank. Understand, communicate with factory technicians and make relevant records.

After the visit, the Korean customers listened to AdTech’ product introduction, development history, future planning, corporate mission, etc. in the conference room, and introduced the AdTech filter board test in the company, reached a batch cooperation intention; coating, Product intentions such as filter box linings have reached the sample.

AdTech will continue to provide the most powerful guarantee for the aluminum foundry industry with excellent product quality and perfect after-sales service.