How To Make Ceramic Foam Filter

Adtech here will let you know how to make ceramic foam filter here.

Preparation of a slip for impregnation of polyurethane foam: potassium salt and phosphoric acid are mixed in a container until completely neutralized.

Then an aluminum-chromophosphate binder is introduced and then, with constant stirring, loose components are introduced: melt, aluminum hydroxide, filler and fine-ground foam ceramic filter waste.

Mixing the suspension continues for 30-40 minutes until complete homogenization.

How To Make Ceramic Foam Filter? Billets made of polyurethane foam with an open-porous elastic structure are impregnated with a finished ceramic slip, and the excess suspension is squeezed out.

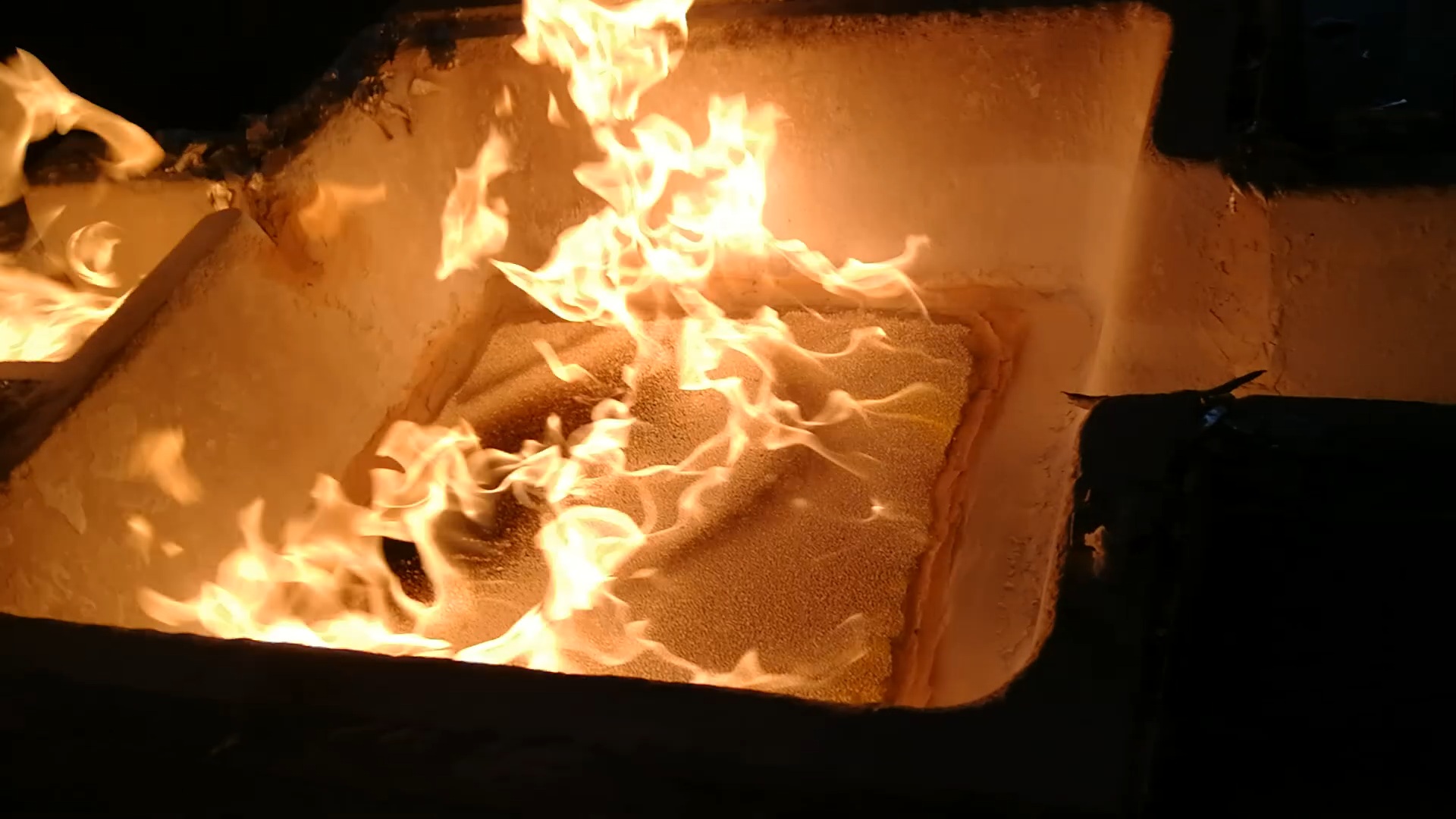

The semi-finished product is dried at a temperature of 100-130 ° C to constant weight and then fired at a maximum temperature of 1280-1290 ° C.

Finished foam filters were tested for resistance by filtration during casting in the form of aluminum alloys.

The compositions of the proposed masses and prototype Physico-technical characteristics obtained during the testing of foam filters.

The proposed solution allows to increase the mechanical strength and heat resistance of ceramic foam filters.

The ceramic foam filters from the proposed mass compares favorably with higher rates of mechanical strength and heat resistance and, very importantly, due to the absence of cracks in the ceramic body, have high bending fracture resistance, which favorably affects the quality of the metal being cleaned.

In addition, the introduction of fine-ground wastes from the PCF allows the organization of waste-free production of ceramic foam filters.

Ceramic foam filters are used to eliminate impurities in metal castings. PPU-based filters remove impurities through their openly porous structure. The paths for molten metal pass through the pores during the casting process. In the direction of ceramic foam filters, PUF serves as a matrix for the further catalytic process. The foam is coated with a ceramic suspension and dried. Then the blanks of various shapes are launched into the furnace, where the matrix of the reticulated polyurethane foam burns out, leaving behind a ceramic mesh frame of the finished filter. Ceramic filter pore sizes range from 10 to 45 PPI / linear inch.

The mesh structure of the ceramic foam filter provides deep filtration, which carefully removes a large amount of impurities without impurities. The filter is able to withstand significant metallostatic pressure, while maintaining effective filtration. Ceramic foam filters are usually used for primary and secondary aluminum smelting, as well as for filters of aluminum smelting furnaces.

Ceramic foam filters have the following advantages

Filtration of metallic and non-metallic impurities from molten metal streams.

Reduction of oxide during turbulent flow formation.

Increased metal flow.

Elimination of inclusions and various metal defects.

Improving the quality of casting, PPU filters have good mechanical properties.

Reduction of scrap and additional work in production.

Ceramic foam filter is available in a wide variety of sizes and shapes.

All ceramic foam filters are characterized by a mesh matrix, spherical pores of uniform size and volume are connected to each other throughout their volume, and form windows through their walls. The winding paths of this structure pass and simultaneously capture molten slag and other contaminants. As a result, this unique PPU-based filter structure shows superior metal filtration efficiency compared to other structures and filters in the foundry market.

Ceramic foam filters have high heat resistance and are easily impregnated with molten metal. The superior durability of PPU-based filters eliminates the need for redundant metal screens.

Improving the quality of casting occurs when filtering slags that are formed in the molten metal during the casting process. With the help of PPU-based filters, the quality of the final casting is improved, the workability of the metal is improved, the casting waste is reduced at the same time, the production speeds of the lines are increased.

Pores in ceramic foam filters act as “traps” for various impurities. This filter structure compares favorably with conventional standard ceramic filters. When the molten mass of ferrous metals comes into contact with the surface of the ceramic foam filter, the special additives that make up the filter coating begin to decompose, and instantly form a continuous film of fayalite. This coating becomes soft and viscous at high temperatures, the fayalite film retains even micron-sized inclusions as they pass through the filter. Conventional ceramic filters are not able to capture so many impurities of molten metal in full.

When using filters from polyurethane foam in the production, you will achieve cleaner metal, improve its fluidity, and in general the quality of the final casting, which will lead to an increase in the profits of the plant and foundry.