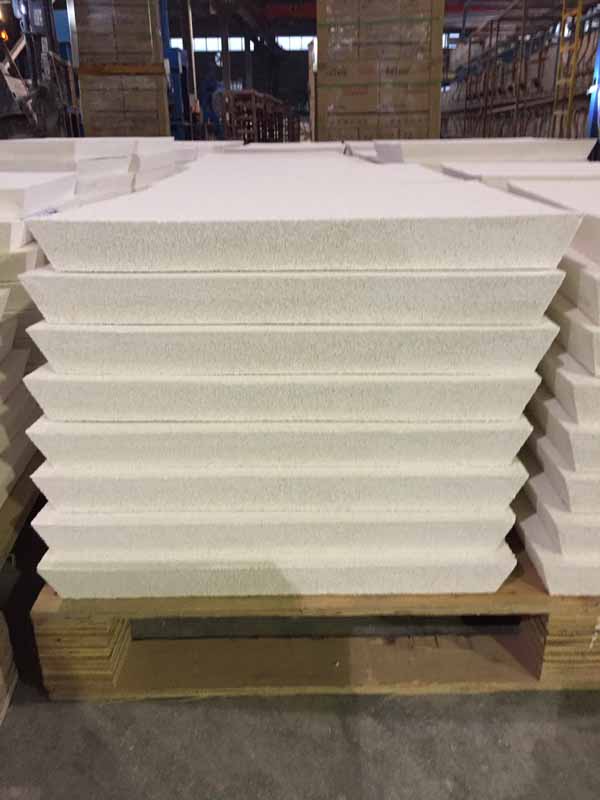

Hot Sale Ceramic Foam Filter from China has a method for preparing and using an AlF3 surface-active alumina foam ceramic filter, which belongs to the field of casting and is used for removing alkali and alkaline earth metal elements in an aluminum melt.

The preparation method is as follows: the prepared alumina ceramics (porosity 80%-90%) are placed in a carbon tube furnace, and HF gas is continuously introduced into the furnace tube, and the heating temperature is 650 ° C – 750 ° C, and the temperature is kept for 15 min – 30 min. It is then taken out of the carbon tube furnace for cooling and drying.

AlF3 surface active alumina foam ceramic filter is used in the process of aluminum melt casting, the thickness of the filter is selected and the casting speed of the aluminum melt is controlled to ensure the time of the aluminum melt flowing through the AlF3 surface active alumina ceramic foam filter. More than 30s

As a result, the removal rates of elements such as [Na], [Li], [Mg], and [Ca] in the aluminum melt were all above 95.00%.

Ceramic filter has been widely approved by the market, applied for producing multiple series of aluminum alloys products….