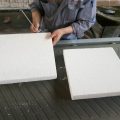

Foundry Ceramic Filters Cambodia is mainly used to filter molten aluminum and alloys in foundries and foundries.

Alumina Ceramic Foam Filter has excellent resistance to molten aluminum erosion and corrosion, can effectively remove inclusions, reduce trapped gas and provide laminar flow, and the filtered metal is significantly cleaner.

Cleaner metals will produce higher quality castings, less scrap and fewer inclusion defects, all of which help increase profits.

Application: Used for aluminum liquid filtration

● Reduce waste related to inclusions

● Reduce costs related to inclusion defects

● Improve productivity through higher extrusion or rolling speed

● Improve casting flexibility by easily changing alloys

●Non-stick aluminum

Foundry Ceramic Filters Feature

● Superior dimensional tolerance

● Stable chemical composition

● Highest filtration efficiency

● Excellent strength

● Resistant to corrosion attack of molten aluminum and alloy

● Beveled edges and compressible washers

Physical Characteristics

Main material: Al2O3, SIO2

Working temperature: ≤1100℃

White color

Hole density: 10/20/30/40/50/60PPI (PPI=number of holes per inch)

Porosity (%): 78-90

Compressive strength (MPa): ≥1.0 (room temperature)

Bulk density (g/cm3): 0.35-0.45

Thermal shock resistance: ≥2 times/800℃-room temperature

Foundry Ceramic Filters Cambodia is basically divided into 6 pore sizes: 10PPI, 15PPI, 20PPI, 25PPI, 30PPI, and 40PPI. The larger the number, the smaller the aperture. But in actual practice, the four types of 10PPI 20PPI 30PP 40PPI can meet the needs of customers.

Aperture selection

1. The casting: 10~25ppi

2. Semi-continuous casting: 30~60ppi

3. High-quality aluminum or sheet: 50~60ppi

4. Continuous casting and rolling: 50~60p