Foundry Ceramic Filters

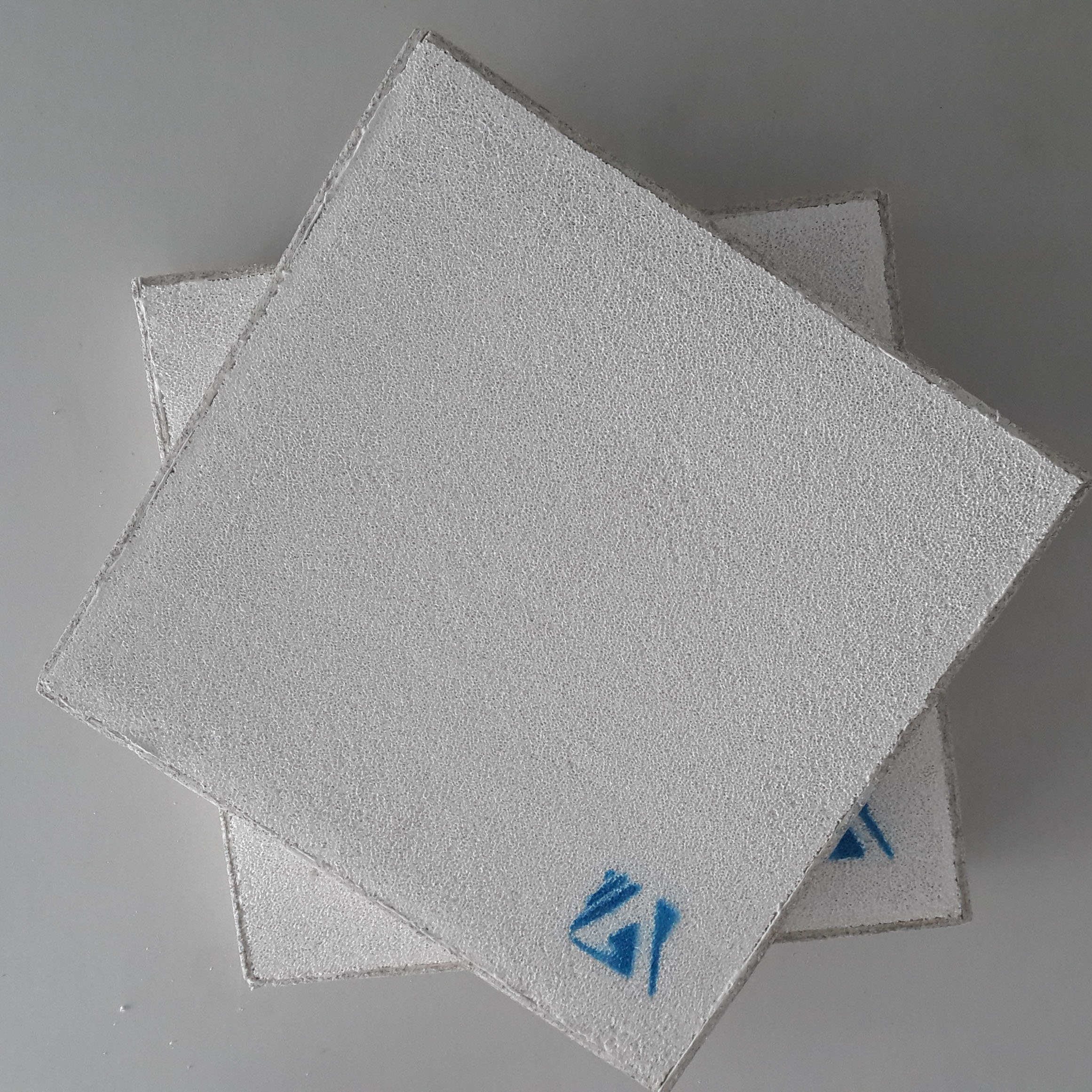

Highly absorbable Foundry Ceramic Filters(CFF) for aluminum alloy casting.

Foundry Ceramic Filters The four-square correction center distance automatic extrusion process is adopted to uniformly apply the slurry to the bubble skeleton of the carrier, and is baked and solidified at a high temperature of 1680 ° C.

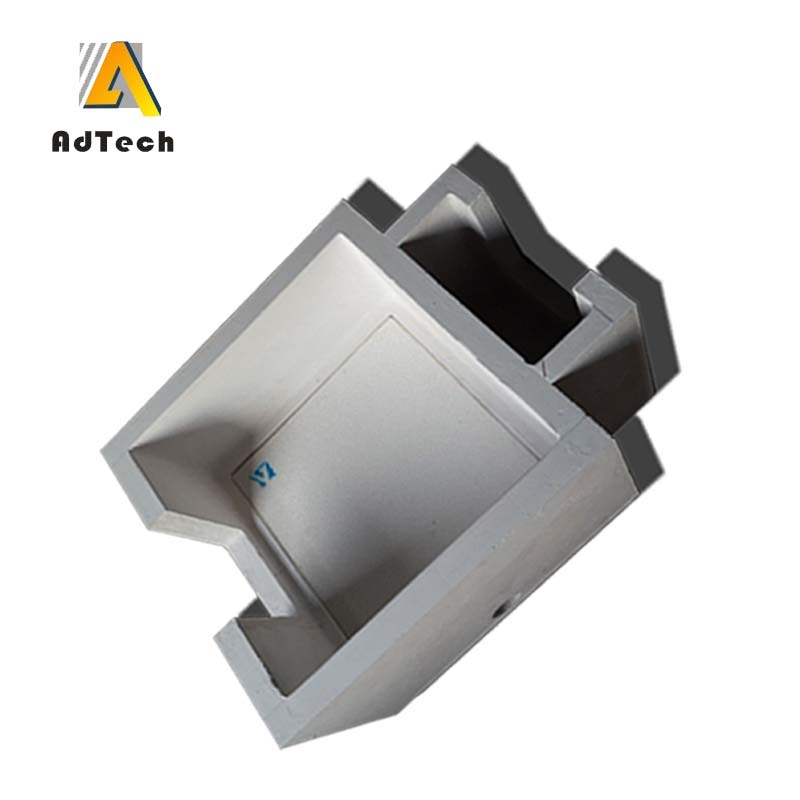

It is installed in the filter box for the impurity filtration of aluminum alloy liquid, and it can meet the high-value-added and high-tech aluminum alloy precision casting of aviation and transportation.

Foundry Ceramic Filters product advantages

1. Foundry Ceramic Filters adopts the principle of adsorption, which can effectively remove large inclusions in aluminum liquid and effectively adsorb fine inclusions of micron size. The filtration efficiency of the same mesh size is high;

2. No slag, effectively reduce the pollution of aluminum liquid;

3. Good thermal shock resistance and improved corrosion resistance to molten metal;

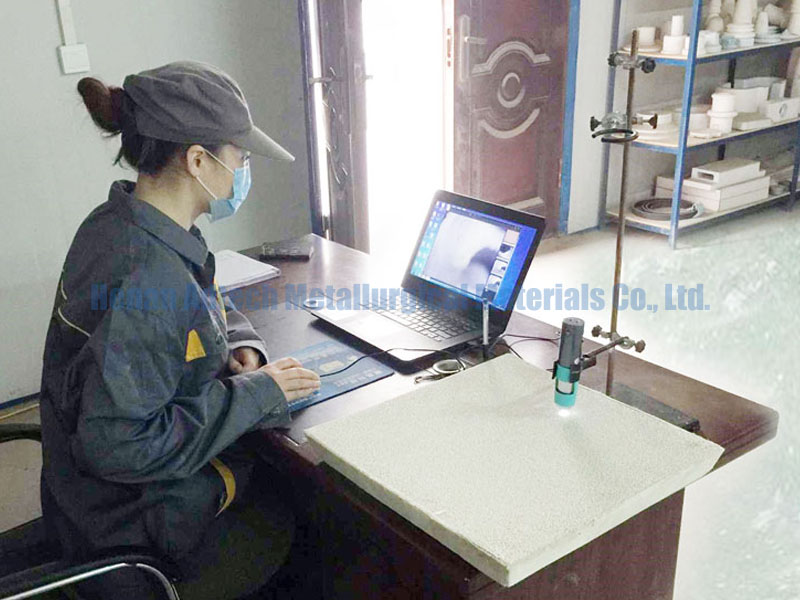

4. Automated assembly line production, three calibration procedures, accurate size, and more suitable for the filter box;

5. Foundry Ceramic Filters improve surface quality, improve product performance, and improve microstructure.

Foundry Ceramic Filters Instructions for Use

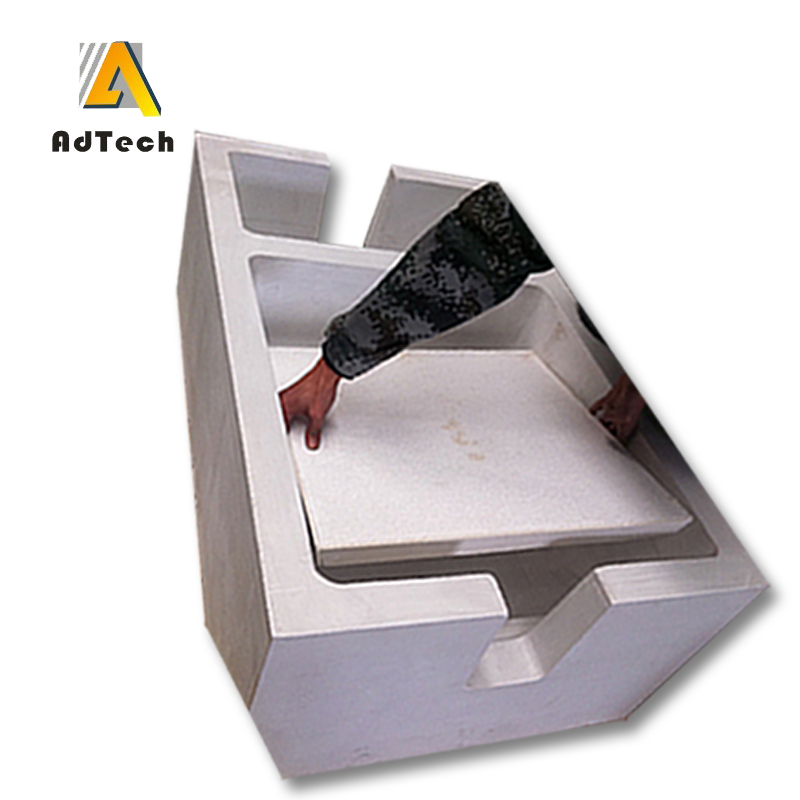

1. Check and clean the surface of the filter box to keep the filter box clean and free from damage.

1. Gently place the Foundry Ceramic Filters into the filter box and press the gasket around the filter plate by hand to prevent the aluminum from flowing or floating.

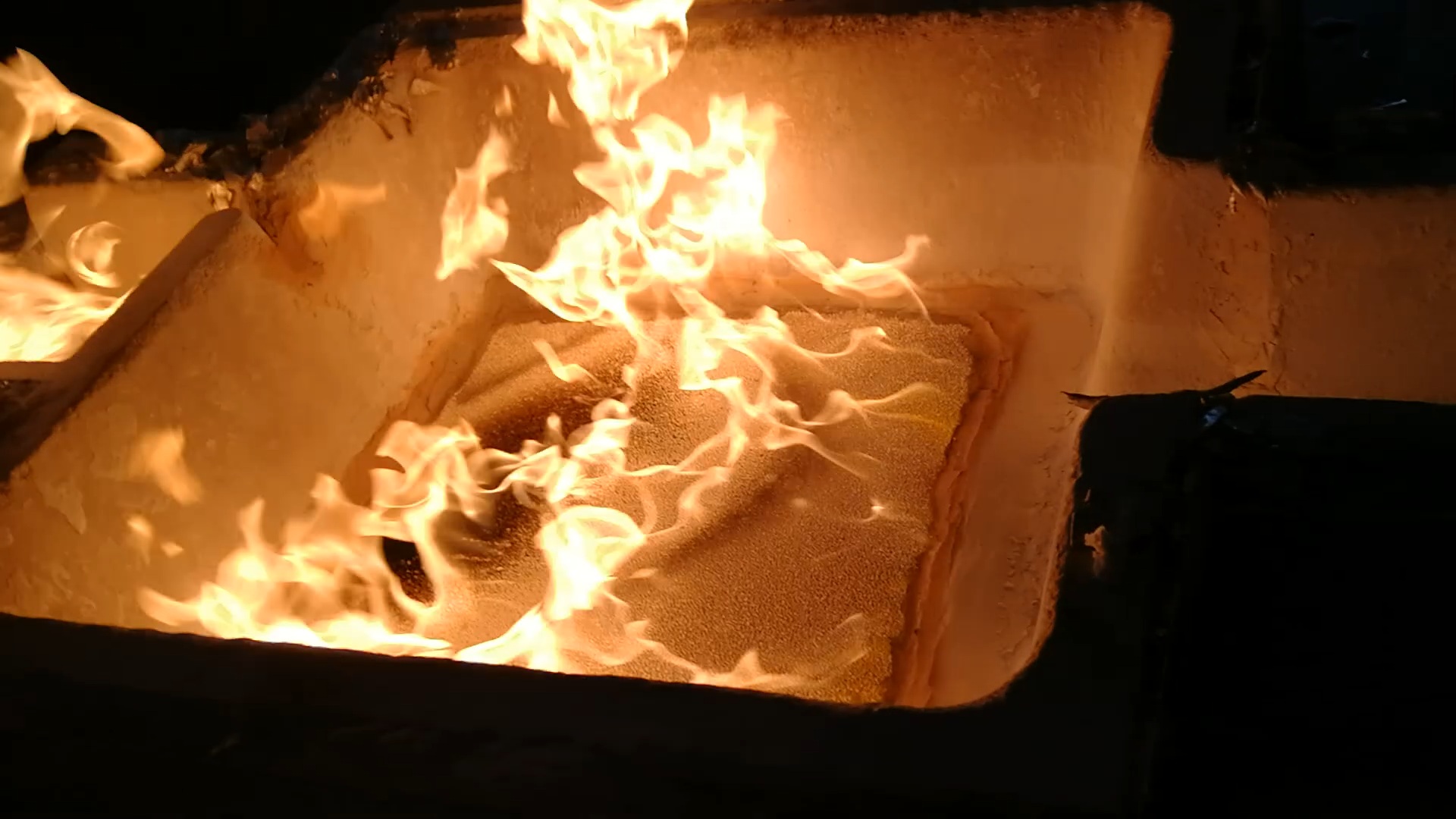

2. Evenly preheat the filter box and Foundry Ceramic Filters to bring it close to the temperature of the aluminum liquid. The preheating temperature of the filter plate is not lower than 260 °C.

Preheating to remove the adsorbed moisture helps to facilitate the initial initial filter pore opening, preventing the heat expansion and contraction from causing partial pore blockage to the filter plate.

Preheating can be heated by electricity or gas, and heated normally for 15-30 minutes.

3. Pay attention to the change of aluminum hydraulic head during casting, and maintain the normal demand of aluminum liquid control flow. The normal starting pressure head is 100-150mm.

When the aluminum liquid begins to pass, the pressure head will drop below 75-100mm, and then the pressure head will gradually increase.

4. Avoid tapping and vibrating Foundry Ceramic Filters during normal filtration. At the same time, the launder should be filled with aluminum water to avoid too much and too little disturbance of the aluminum liquid.

5. After the filtration is finished, remove the Foundry Ceramic Filters and clean the filter box.

[…] the modern aluminum casting industry, in the process of producing aluminum products, Foundry Ceramic Filters can effectively remove the alumina impurities in the aluminum liquid, and increase the quality of […]

[…] system and the hot top casting platform. During the solidification of the metal, the ability of Foundry Ceramic Filters to capture these inclusions is critical to keeping the steel ingot clean. This ensures the quality […]