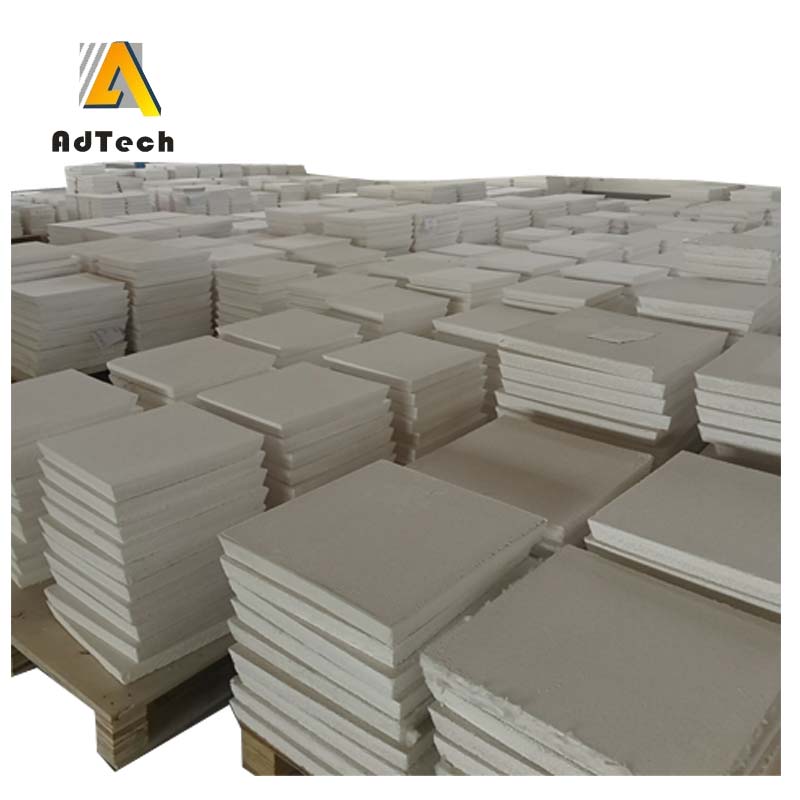

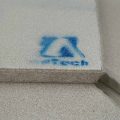

Foam Filter Material Product for aluminium casting is based on a carrier with a solid network structure and combined with organic foam cells.

Production steps

The carrier is put into the thixotropic alumina slurry, and the square-centered automatic extrusion process is adopted to make the slurry dry and solidify and deposit evenly on the foam skeleton of the carrier.

The carrier is then calcined at a high temperature of 1180°C to form the final product.

The ceramic filter is surrounded by a gasket, which is located between the filter and the filter cup to prevent the molten aluminum from leaking through the interface. AdTech’s filters use three different types of gaskets, namely fiber paper material, fiber cotton material, and expanded cotton material.

Advantages of Foam Filter Material Product for aluminium casting

The filter adopts the principle of adsorption, which can effectively remove large inclusions in molten aluminum, and effectively adsorb small inclusions.

No debris falls off, effectively reducing the pollution of molten aluminum.

Excellent thermal shock resistance, improve the erosion resistance of molten metal.

Improve surface appearance and performance, purify molten aluminum.

High-grade ceramic foam filters-these filters are only used for aluminum castings. Currently, market-leading suppliers offer various sizes and thicknesses.

You must choose the right one according to your requirements.

If your requirements are not suitable for common sizes, you can order custom sizes.

In order to avoid re-oxidation of molten aluminum during casting, pressureless casting technology can be used.

It increases the productivity of the manufacturer while preparing the filter for the next large shipment.

Ceramic foam filter Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

Ceramic foam filter Pore Size (PPI): 10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.