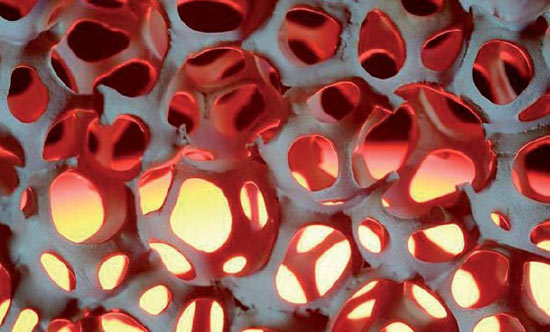

Foam Filter

The usage of Ceramic Foam Filter (CFF) grew continuously in metal casting process, for the reason that of the value added is greater than the cost of filter application and cost for purchasing filter. Whereas 20 years ago filter were used only in emergency cases but at present filter can be considered an integral part of casting (Sadon et al., 2001).

This is due to the advantages of the metal filtration which can be divided into three categories such as benefit to the foundry, benefits to the foundry`s customer and benefit to the final cast product (Schmahl and Aubrey, 1993b) .

Since 1976-2007 several efforts had been done to fabricate various ceramic foam filters in foundry industry include U.S.

Low expansion corrosion resistant ceramic foam filters for molten aluminum filtration 2007). Although all of the filters which have been fabricated in these patents have achieved acceptable ideal properties (high thermal shock resistance,adequate strength and low density), but none of them have been able to reach an acceptable price.

Therefore the present research has been done to fabricate ceramic foam filter for filtration of aluminum alloy with new cheaper additives materials and improve a ceramic foam filter for using in filtration of molten metal, especially aluminiumbased alloys.

FABRICATION OF CERAMIC FOAM FILTER

The experimental procedures for fabrication of ceramic foam filter are explained from section 2.1 to 2.6. The present ceramic foam filters are produced by immersing the polymeric sponge with an aqueous ceramic slurry, then burn out to leave a porous ceramic.

EXPERIMENTAL RESULTS

In this paper the ceramic form filter is measure in term of flow modification, weight and volume test, surface inspection, macro and micro structure.